Description

EMG ECU01.5 (ECU01 Series) – Analog Input Module for Precise Industrial Signal Acquisition

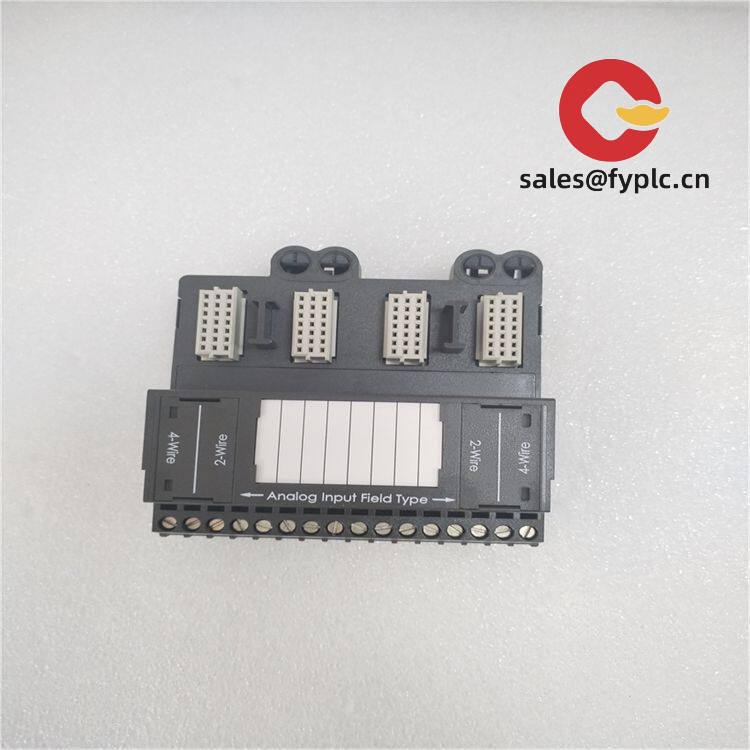

The EMG ECU01.5, part of the ECU01 series, is an analog input module designed for reliable signal acquisition in industrial control cabinets. From my experience, it fits well when you need clean, stable readings from field transmitters—think 4–20 mA loops and 0–10 V sensors—without fighting noise or drift. You might notice that it’s built for typical DIN-rail environments and integrates via the system backplane, which keeps wiring tidy and commissioning straightforward.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment, full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Multi-range analog inputs – Typically supports 0–10 V, 0–5 V, 4–20 mA, and 0–20 mA so you can standardize on one module across different sensors.

- Industrial-grade accuracy – 16-bit class A/D conversion in many cases, giving stable readings for closed-loop control and trending.

- Channel isolation – Designed with input-to-bus isolation to reduce ground loops and noise coupling in mixed-signal cabinets.

- Backplane integration – Communicates via the EMG system backplane; no external comm wiring needed, which simplifies installation.

- DIN-rail friendly – Slim module footprint helps keep panel width under control in brownfield retrofits.

- Diagnostics LEDs – At-a-glance channel and status indicators to speed up commissioning and troubleshooting.

- Shielded wiring practices – Terminal layout is typically arranged for clean routing of shield and common, which minimizes EMI issues.

Technical Specifications

Note: Values below reflect typical configurations for the ECU01 series and the ECU01.5 variant. Minor differences can exist by firmware or revision; we can verify exact data against your serial and BOM before shipment.

| Brand / Model | EMG / ECU01.5 (ECU01 Series) Analog Input Module |

| HS Code | 8537.10 (Programmable control equipment) |

| Power Requirements | 24 VDC via backplane; typically 3–5 W module consumption |

| Analog Inputs | 4 channels, configurable per channel: 0–10 V, 0–5 V, 4–20 mA, 0–20 mA; 16-bit typical resolution; input-to-bus isolation |

| Signal Input/Output Types | Voltage and current analog inputs; pluggable screw or spring terminals (field) |

| Communication Interfaces | Backplane bus to EMG controller; no external port required |

| Installation Method | DIN rail (EN 60715) inside control cabinet |

| Dimensions & Weight | Approx. 115 × 99 × 25 mm; ~0.15 kg |

| Operating Temperature | 0 to +55 °C (cabinet-mounted, non-condensing) |

Application Fields

This module is widely used where stable analog measurements are critical:

- Metals processing: strip thickness, roll gap, hydraulic pressure and coolant temperature monitoring

- Paper & converting: tension feedback, nip pressure, web guide sensors

- Chemical & process: flow, level, and pH transmitters on 4–20 mA loops

- Power & utilities: valve positioners, analog feedback from transducers

- General machine building: servo hydraulic control feedback and temperature sensing

“We swapped in ECU01-series AI modules on an older line. Noise dropped noticeably and our trending finally matched the handheld calibrator.” — Maintenance Lead, coil coating plant

Advantages & Value

- Reliability – Robust isolation and conservative thermal design typically help the module run for years in closed cabinets.

- Compatibility – Works within the EMG ECU01 backplane ecosystem; mixed voltage/current channels reduce spares.

- Cost savings – Less panel rework thanks to DIN-rail profile; reduced downtime through quick diagnostics LEDs.

- Technical support – We can assist with signal scaling, wiring diagrams, and recommended shielding/grounding practices.

Installation & Maintenance

- Cabinet environment – Mount on EN 60715 DIN rail in a ventilated enclosure; maintain airflow around modules; avoid mounting near VFDs without shielding.

- Wiring – Use shielded twisted pair for current loops and route sensor cables away from power; terminate shields at one end to prevent ground loops.

- Power – Supply clean 24 VDC to the backplane; include proper grounding and surge protection, especially in high-EMI plants.

- Safety – De-energize cabinet before inserting/removing modules; verify channel range and scaling prior to live tests.

- Routine maintenance – Periodically check terminal tightness, clean dust with dry air, and verify calibration against a traceable source; plan firmware updates where applicable.

Quality & Certifications

- CE compliant (EMC and Low Voltage directives)

- RoHS compliant

- Manufactured under ISO 9001 quality systems

- Warranty: 12 months from delivery

Suggested Supporting Components

- ECU01 backplane base and end-clamps for DIN rail

- 24 VDC redundant power module (for higher availability cabinets)

- Shielded I/O cable sets and labeled terminal blocks

- Panel surge protection for analog loops and 24 VDC rails

One thing I appreciate is how the ECU01.5 seems to balance resolution with noise immunity; you don’t have to overcomplicate filtering to get stable values. If you share your sensor types and ranges, we can confirm the exact channel configuration and ship the correct variant right away.

Reviews

There are no reviews yet.