Description

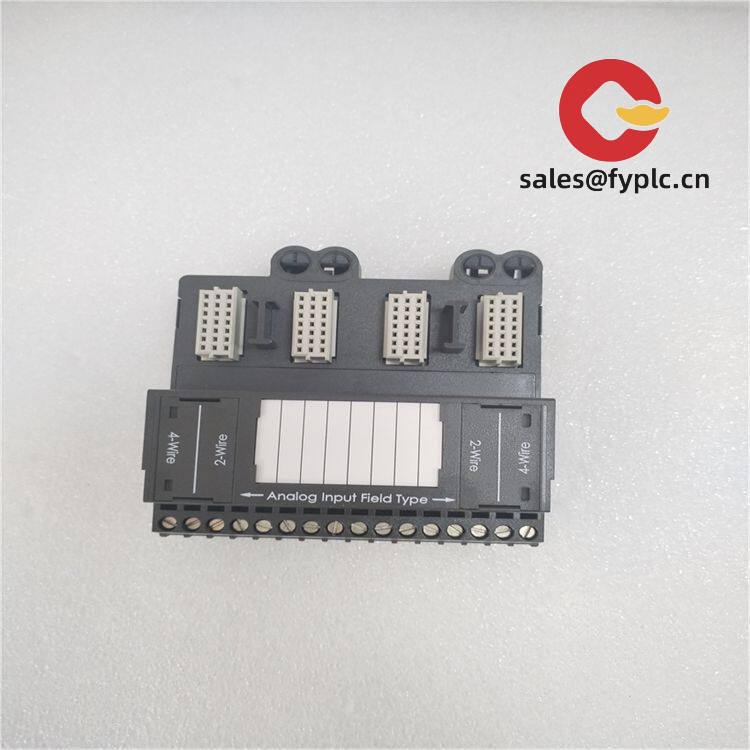

Emerson VE4033S2B1 Redundant Analog Input Card – Reliable 4–20 mA acquisition for high-availability process control

The Emerson VE4033S2B1 is a redundant analog input card engineered for continuous process industries where uptime matters. From my experience, plants choose this module when they need stable 4–20 mA signal collection with the option to run in a redundant pair for switchover without losing data. It typically slots into the Emerson system backplane and integrates with plant asset management, so you can pull diagnostics and HART data (where enabled) alongside your process variables. One thing I appreciate is how predictable the commissioning feels—wiring, auto‑recognition, and channel checks are straightforward in most cases.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Redundant operation – Designed to be deployed as a redundant pair for bumpless transfer and higher availability.

- 4–20 mA analog inputs – Stable, low‑noise measurement for common transmitters in oil & gas, chemical, power, and water.

- HART pass‑through (where configured) – Access device diagnostics and secondary variables without extra wiring.

- Backplane integration – No external power required; communicates over the Emerson system backplane for configuration and diagnostics.

- Hot‑swap capable – In many cases you can replace the card online on a redundant system to minimize downtime.

- Channel health and diagnostics – Open circuit, over‑range, and wiring status help technicians pinpoint issues faster.

- Compact footprint – Fits the standard Emerson I/O carrier, simplifying spares strategy and cabinet layout.

Technical Specifications

| Brand / Model | Emerson VE4033S2B1 (Redundant Analog Input Card) |

| HS Code | 8537.10 (Boards/panels for electric control; programmable controller assemblies) |

| Power Requirements | Backplane powered from the Emerson I/O carrier; no external supply required |

| Signal Inputs | 4–20 mA analog inputs; HART pass‑through typically supported on compatible channels |

| Redundancy | Supports redundant pairing for high availability and online maintenance |

| Communication Interfaces | System backplane to the controller/processor; asset management integration where enabled |

| Operating Temperature | Typically 0 to 55 °C (consult system manual for exact limits) |

| Installation Method | Plug‑in module on the Emerson I/O carrier/baseplate; DIN‑rail or panel mount cabinet assemblies |

| Dimensions & Weight | Compact plug‑in form factor (approx. small‑module size used across Emerson I/O); light weight for easy hot‑swap |

Note: Channel count and certain electrical limits can vary by system revision and carrier. If you share your installed base details, we can validate exact fit and specifications.

Application Fields

- Refining and petrochemical – reliable transmitter inputs on critical loops (flow, pressure, temperature).

- Power generation – boiler drum level, turbine auxiliary systems, and balance-of-plant analog signals.

- Water and wastewater – lift station pumps, clarifier monitoring, and chemical dosing feedback.

- Pharmaceutical and food – utility skids, CIP/SIP temperature and pressure monitoring.

- Metals and mining – slurry density, reagent feed, and utility monitoring in harsh environments.

Advantages & Value

- High availability – Redundant architecture reduces unplanned downtime and allows online maintenance.

- Lifecycle alignment – Compatible with mainstream Emerson system backplanes, simplifying migrations and spares pooling.

- Total cost control – Backplane power and hot‑swap reduce installation time and outage planning costs.

- Diagnostics – Early warning on wiring faults and device issues cuts troubleshooting time.

- Supportability – Documentation, firmware tools, and widely used practices across sites make it easier to maintain with existing teams.

Installation & Maintenance

- Cabinet & carrier – Install on the matching Emerson I/O carrier in a clean, ventilated cabinet (IP54 or better is typical for plant areas).

- Wiring – Use shielded twisted pair for 4–20 mA. Land shields at one end to avoid ground loops. Verify channel polarity before energizing.

- Ventilation – Maintain airflow around modules; avoid mounting near heat sources. Keep ambient within specified temperature.

- Redundant pairing – For high availability, commission as an A/B pair and confirm switchover logic prior to cutover.

- Routine care – Periodic terminal re‑torque checks, dust cleaning with dry air, and firmware updates (if applicable) during planned outages.

- Safety – De‑energize field loops or use proper bypass procedures. Follow site LOTO and ESD handling practices when hot‑swapping.

Compatible Accessories & Spares

- I/O carrier/baseplate – Matching Emerson carrier for VE‑series cards; provides backplane power and bus communications.

- Field terminal blocks – Shielded terminal assemblies for clean terminations and easier loop checks.

- Redundant mate module – Second VE4033S2B1 to form an A/B redundant pair.

- HART modem or multiplexer – For asset management and remote device diagnostics on HART‑enabled channels.

- Spare fuses and labels – For cabinet upkeep and rapid maintenance during turnarounds.

Quality & Certifications

- CE compliance for EMC and safety (typical for Emerson I/O modules)

- UL/CSA certification for industrial control equipment

- RoHS conformity for hazardous substances

- Manufacturer warranty: 12 months (365 days)

You might notice that noisy transmitters settle down after enabling proper shielding and checking the card’s channel filters. One maintenance supervisor from a chemical plant told me the redundant pair let them swap a suspect module mid‑shift without touching the running loop—no PV bump on the operator screen.

Reviews

There are no reviews yet.