Description

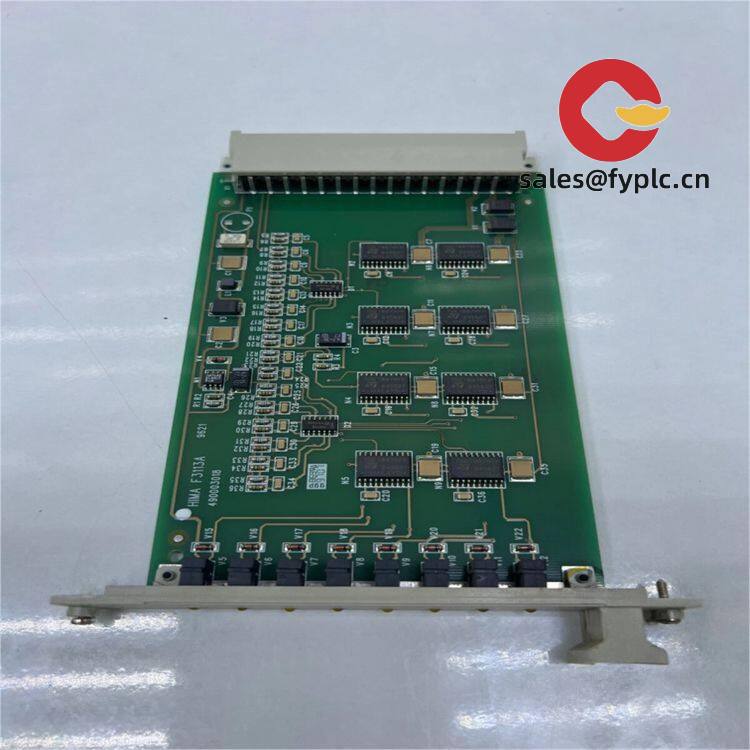

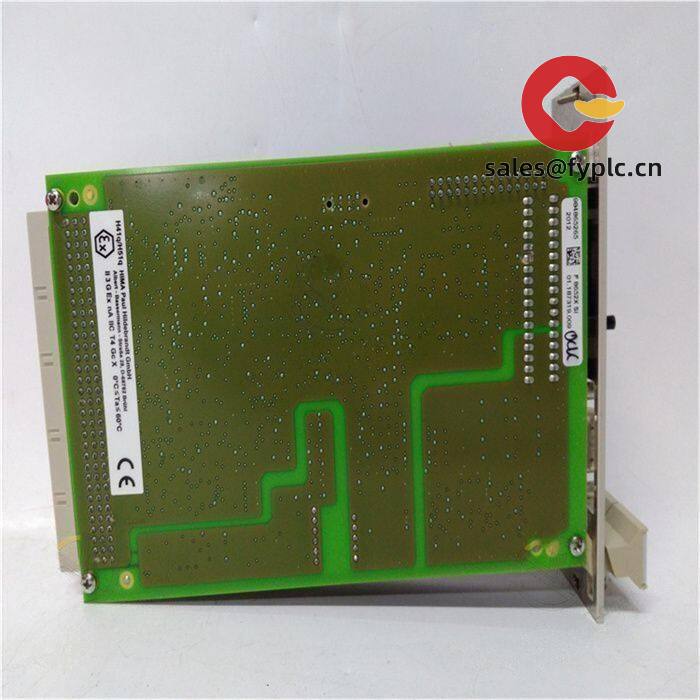

HIMA F2102 – Smart Safety Module for High-Integrity Shutdown and Interlocks

The HIMA F2102 is a smart safety I/O module designed for use in HIMA safety systems, typically deployed in ESD, F&G, turbomachinery protection, and other SIL-classified applications. It slots into a HIMA backplane and works with SILworX engineering software, giving you deterministic safety logic, detailed diagnostics, and the kind of reliability plants expect from HIMA. From my experience, the F2xxx family is often chosen when teams want robust, line-monitored I/O and straightforward maintenance in critical environments.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- SIL-ready design – Built for use in IEC 61508 safety architectures (SIL 2/3 applications, system-dependent), giving predictable behavior in trip scenarios.

- Safety I/O with line monitoring – Channels typically support line fault detection (open/short), which makes finding field wiring issues faster.

- Rich diagnostics – Front-panel indicators and system diagnostics in SILworX help maintenance spot a failing loop before it becomes a nuisance trip.

- Backplane integration – Seamlessly integrates into HIMA racks; parameters and firmware handled via the system backplane, not point-to-point.

- Hot-swap capability – In many cases, modules can be replaced online in redundant architectures, reducing mean time to repair.

- Galvanic isolation – Channel and system isolation improves immunity to noise and minimizes ground loop troubles in brownfield plants.

- Time stamping and SOE – You might notice that events are captured with precise timing, helping post-trip analysis and audit trails.

- Engineered in SILworX – Centralized configuration, version control, and proof-test documentation support normal and turnaround workflows.

Technical Specifications

| Brand / Model | HIMA F2102 Smart Safety Module |

| HS Code | 85371000 (Industrial control equipment, ≤1000 V) |

| Power Requirements | Backplane supplied, typically 24 V DC system power (provided by the HIMA rack/PSU) |

| Signal I/O Types | Safety I/O module; common variants provide 24 V DC digital inputs/outputs with line monitoring and isolation (exact channel mix variant-dependent) |

| Communication Interfaces | Internal system bus via HIMA backplane; engineered and diagnosed via SILworX |

| Installation Method | Plug-in module for HIMA rack/baseplate; cabinet-mounted in control panels with proper grounding and ventilation |

| Operating Temperature | Typically 0…60 °C (32…140 °F), non-condensing; confirm per exact module revision |

| Dimensions & Weight | Plug-in card format; approx. 100–130 mm height, 25–35 mm width; ~0.2–0.3 kg (typical for HIMA F2xxx modules) |

| Safety Integrity | For use in SIL 2/3 architectures (IEC 61508), depending on system configuration and proof test intervals |

Application Fields

- Emergency Shutdown (ESD) and High-Integrity Pressure Protection (HIPPS) in oil & gas and petrochemical plants

- Fire & Gas (F&G) detection, cause & effect, and shutdown logic in onshore/offshore facilities

- Turbomachinery protection, burner management, and compressor anti-surge systems

- Safety interlocks for pharmaceuticals and specialty chemicals where batch safety is critical

- Power generation balance-of-plant safety trips and auxiliary protection

A maintenance supervisor told me their team cut loop-fault troubleshooting time by “at least half” after moving critical points onto F2xxx safety I/O with proper line monitoring. It seems to be these small diagnostics that save hours during a turnaround.

Advantages & Value

- Reliability you can audit – Proven safety behavior, hot-swap in redundant setups, and detailed SOE data for incident reviews.

- Compatibility – Works within HIMA safety platforms and toolchain (SILworX), easing integration with existing cabinets and documentation.

- Lifecycle savings – Fewer nuisance trips and faster fault finding typically reduce unplanned downtime and callouts.

- Supportable – Clear diagnostics, guided proof-test routines, and spare interchangeability make procurement and maintenance simpler.

Installation & Maintenance

- Cabinet environment: Install in an industrial control cabinet (IEC/UL), with clean, dry air and adequate ventilation; avoid vibration and conductive dust.

- Grounding & wiring: Maintain proper shield termination and single-point grounding. Use certified intrinsically safe barriers where required.

- Backplane & slots: Seat the module firmly in the designated slot of the HIMA rack/baseplate; check keying to avoid misplacement.

- Hot-swap practice: If hot-swapping in a redundant system, follow plant MOC and HIMA procedures; verify channel state and permissives before reinsertion.

- Routine maintenance: Visual inspection for connector wear, clean with lint-free swabs, verify LED diagnostics, and back up configurations.

- Functional testing: Perform proof tests at intervals defined by your SIL calculations; document results in SILworX for audit trails.

- Firmware/Tools: Keep SILworX and module firmware at approved versions after change control; test in a staging environment first.

Quality & Certifications

- Designed for use in systems assessed to IEC 61508 (SIL 2/3, application-dependent)

- CE conformity for EMC and Low Voltage (module/system dependent)

- UL/cUL recognition in many installations (verify per exact variant and panel listing)

- RoHS compliant manufacturing; ISO 9001 quality system

- Manufacturer warranty: 12 months

Supporting Components (Typical)

To complete a system, plants typically pair the F2102 with HIMA CPU modules, redundant power supply modules, and the appropriate HIMA rack/baseplate, all engineered in SILworX. If you share your rack type and channel counts, I can match the exact module variant and accessories so it fits first time.

Reviews

There are no reviews yet.