Description

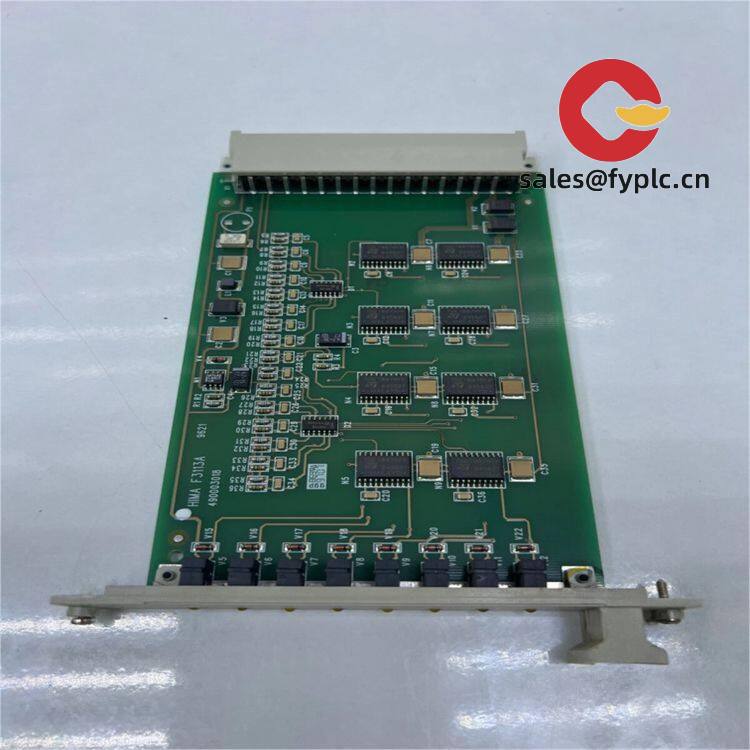

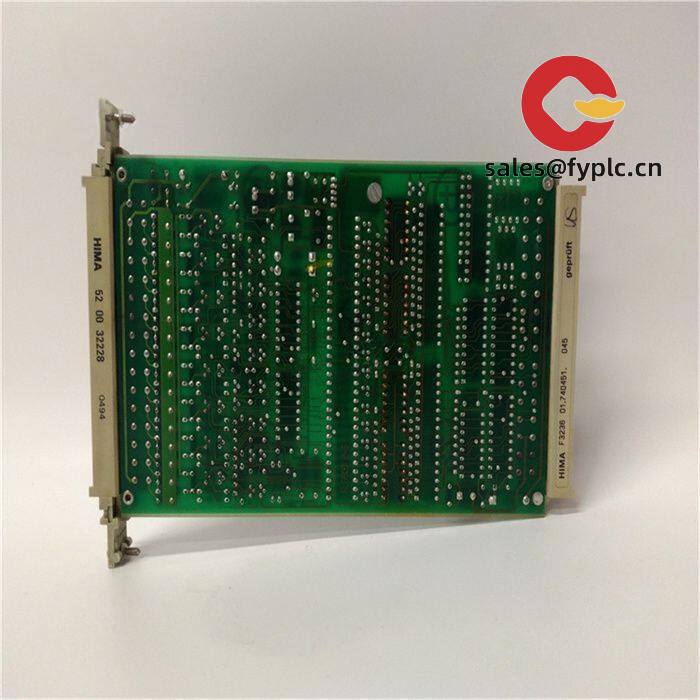

HIMA F3222 Digital Input Module – Reliable 24 VDC Safety-Critical Signal Acquisition

The HIMA F3222 is a digital input module designed for safety PLC systems where reliable, deterministic capture of field signals really matters. From my experience, it’s typically used to bring in 24 VDC discrete signals with built-in diagnostics and line monitoring, so you can detect wiring faults before they become production problems. If you’re expanding a HIMA safety controller or replacing a legacy DI card, the F3222 slots in neatly and keeps your proof-test and maintenance routines straightforward.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Safety-grade digital inputs: Optimized for 24 VDC signals in safety-related applications, typically supporting SIL 3 architectures.

- Line monitoring and diagnostics: Detects wire break and short-circuit conditions to reduce troubleshooting time.

- Configurable input filtering: Adjustable debounce/filter times help reject noise in harsh electrical environments.

- Backplane integration: Communicates via system backplane; no external comm ports needed or extra wiring overhead.

- Hot-swap friendly design (system dependent): In many HIMA racks, modules can be replaced with minimal downtime when procedures are followed.

- Front connector access: Field wiring via front connector for quick install, tidy cable management, and easy maintenance.

- Robust operating range: Built for industrial cabinets where temperature swings and electrical noise are the norm.

Technical Specifications

| Brand / Model | HIMA F3222 |

| HS Code | 8538.90 (Parts for electrical control equipment) |

| Power Requirements | Supplied via system backplane (24 VDC system supply, typical) |

| Operating Temperature | -20 to +60 °C (typical for HIMA safety I/O) |

| Signal Input Type | 24 VDC digital inputs with diagnostic/line monitoring; configurable filtering |

| Communication Interfaces | Internal backplane bus to safety controller; no user-facing comm ports |

| Installation Method | Plug-in module for HIMA safety PLC racks; front connector field wiring |

| Dimensions & Weight | Standard HIMA plug-in form factor; approx. 0.4–0.5 kg (system variant dependent) |

Application Fields

You’ll typically see the F3222 used where shutdown functions and interlocks depend on clean, time-accurate digital inputs:

- Oil & gas (ESD/PSD, burner management, compressor protection)

- Chemical and petrochemical plants (SIS input collection, permissives, trips)

- Power generation and boiler safety (flame safeguard interlocks, valve feedback)

- Pharmaceutical and fine chemicals (critical utilities and containment safety)

- Rail and infrastructure (where certified safety inputs are required)

A maintenance lead in a refinery told us they value the module’s fault detection because it “flags a cable issue during the turnaround, not during startup,” which is exactly the kind of detail that saves a day on the critical path.

Advantages & Value

- Reliability: Engineered for high availability; diagnostic coverage improves proof-test outcomes and uptime.

- Compatibility: Works within HIMA safety PLC ecosystems, so expansion and spares strategies stay simple.

- Cost control: Early fault detection and channel diagnostics typically reduce field callouts and wiring rework.

- Lifecycle support: From my experience, firmware and configuration tools are stable, keeping validation and requalification effort manageable.

Installation & Maintenance

- Cabinet environment: Install in a clean, ventilated control cabinet; maintain ambient within the specified temperature range.

- Wiring: Use shielded cables for noisy areas; observe HIMA grounding, segregation, and terminal torque guidance.

- Backplane/system: Ensure the rack power budget supports the added module; reserve I/O addresses as per project configuration.

- Hot swap & safety: If your HIMA rack supports online replacement, follow the approved procedure; otherwise isolate power before removal/insertion.

- Routine maintenance: Periodically verify channel status LEDs, clean connectors, check line-monitoring thresholds, and apply approved firmware updates during planned outages.

- Proof testing: Execute functional tests at the interval defined by the SIS/SIF design to maintain target SIL.

Quality & Certifications

- Conforms to CE requirements

- TÜV certification to IEC 61508 (SIL 3 capable), typical for HIMA safety I/O

- UL/cUL and RoHS compliance in many cases (check project-specific variant)

- Manufacturer’s warranty practices apply; we provide a 365-day warranty on supply

Note: Specifications can vary slightly by system version and firmware. If you share your rack type and controller version, we can confirm exact channel capabilities and accessories (front connector options, labeling kits).

Reviews

There are no reviews yet.