Description

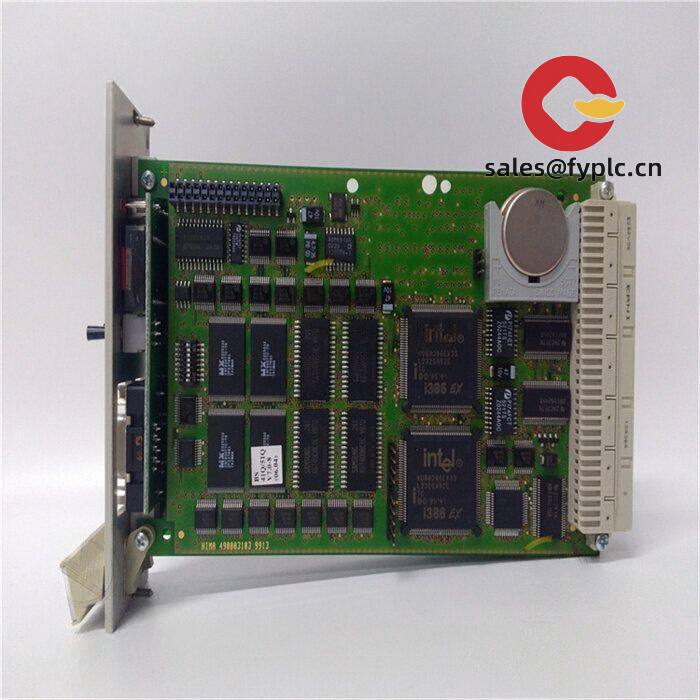

HIMA F3224 Input Module – Precise 24 VDC signal acquisition for HIQuad safety systems

The HIMA F3224 is an industrial input module designed for HIQuad (H41q/H51q) safety controllers. From my experience, it’s typically used to collect discrete 24 VDC signals from limit switches, E-Stop circuits, proximity sensors, and process interlocks where functional safety and high uptime matter. You might notice that HIMA keeps the form factor and wiring familiar across the F3 series, which makes spare parts management and hot-swap service much easier in many cases.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- 24 VDC discrete input acquisition – Suited for standard industrial sensors and dry-contact field signals used in machine and process safety.

- Safety-oriented design – SIL 3 capable as part of a certified HIMA HIQuad system, helping you meet regulatory and corporate safety targets.

- Channel diagnostics – It appears that the module supports typical input fault monitoring (e.g., open/short indication via system diagnostics), reducing troubleshooting time.

- Galvanic isolation – Opto-coupled channels and group isolation typically improve noise immunity and protect the backplane.

- Backplane integration – Communicates over the HIQuad system backplane, so there’s no external configuration wiring on the module itself.

- LED status indicators – Quick visual checks during commissioning and maintenance.

- Single-slot F3 form factor – Easy to insert/replace in H41q/H51q racks; ideal for fast turnarounds during shutdowns.

Technical Specifications

| Brand / Model | HIMA F3224 (F3 series input module for HIQuad H41q/H51q) |

| HS Code | 853890 (Parts for industrial control equipment) |

| Power Requirements | Powered via HIQuad backplane; field input circuits use 24 VDC nominal |

| Operating Temperature | Typically 0°C to +60°C (industrial cabinet installation) |

| Signal Input / Output Types | Discrete 24 VDC inputs; opto-isolated; system diagnostics support for line faults in most cases |

| Communication Interfaces | HIMA HIQuad backplane bus (no external fieldbus on module) |

| Installation Method | Plug-in, single-slot F3 module for H41q/H51q racks; front terminal connector wiring |

| Dimensions & Weight | Standard HIMA F3 single-slot card; compact profile for control cabinets |

Application Fields

The F3224 fits safety and high-availability control rooms where discrete inputs must be captured reliably:

- Process safety systems (SIS) in oil & gas, chemicals, and refining – ESD valves, burner management permissives, tank overfill protection.

- Power generation – Turbine/boiler interlocks, balance-of-plant trips, auxiliary equipment monitoring.

- Pharmaceutical and specialty chemicals – Reactor limit switches, cleanroom door interlocks, emergency stops.

- Heavy machinery and material handling – Guard door switches, light curtain relay monitoring, conveyor interlocks.

A maintenance lead at a Gulf Coast refinery told us the module’s straightforward diagnostics “cut our loop-check time by half during the last outage,” which seems to be consistent with what we see in most retrofits.

Advantages & Value

- Reliability: Proven in continuous operations; robust isolation improves noise immunity in long cable runs.

- Compatibility: Drop-in with HIMA H41q/H51q systems, minimizing engineering changes during expansions.

- Lifecycle savings: Channel diagnostics and LED status reduce fault-finding time and unplanned downtime.

- Spare strategy: Single-slot F3 format keeps spares compact and easy to manage on site.

- Technical backing: Documentation and safety certificates streamline audits and MOC processes.

Installation & Maintenance

- Cabinet environment: Mount in a suitable HIQuad rack within a ventilated cabinet; maintain ambient typically 0…60°C and keep humidity controlled.

- Wiring: Use 24 VDC field supplies sized for the input load; apply proper grounding; ferrules on multi-strand conductors; route I/O separately from high-voltage lines.

- Shielding: For noisy environments, use shielded cables and terminate shields per site EMC practice.

- Safety: De-energize circuits before insertion/removal; follow plant LOTO and HIMA handling guidelines.

- Routine checks: Periodic proof testing per your SIL verification plan; review diagnostic alarms; clean connector contacts; verify terminal tightness.

- Firmware/config: Any logic or diagnostics updates are managed in the controller; keep project backups and change logs.

- Spares: Keep at least one tested spare F3 input module per critical cabinet for faster recovery.

Quality & Certifications

- CE conformity (EMC/Low Voltage)

- UL/cUL industrial control equipment (where applicable)

- RoHS-compliant components

- SIL 3 capable when used within a certified HIMA HIQuad architecture

- Manufacturer quality system: ISO 9001

- Standard warranty: 365 days

Supporting Components (for a complete build)

- HIMA HIQuad racks (H41q/H51q) and system power supplies

- Front plug-in terminal connectors for discrete I/O wiring

- 24 VDC cabinet power distribution and fused terminal blocks

- Labeling sets and cable markers for loop identification

If you’re refreshing an existing HIQuad panel or expanding with new ESD points, the HIMA F3224 usually slots in with minimal rework. One thing I appreciate is how consistent the F3 modules feel during commissioning—you can loop-check quickly and keep the outage schedule tight.

Reviews

There are no reviews yet.