Description

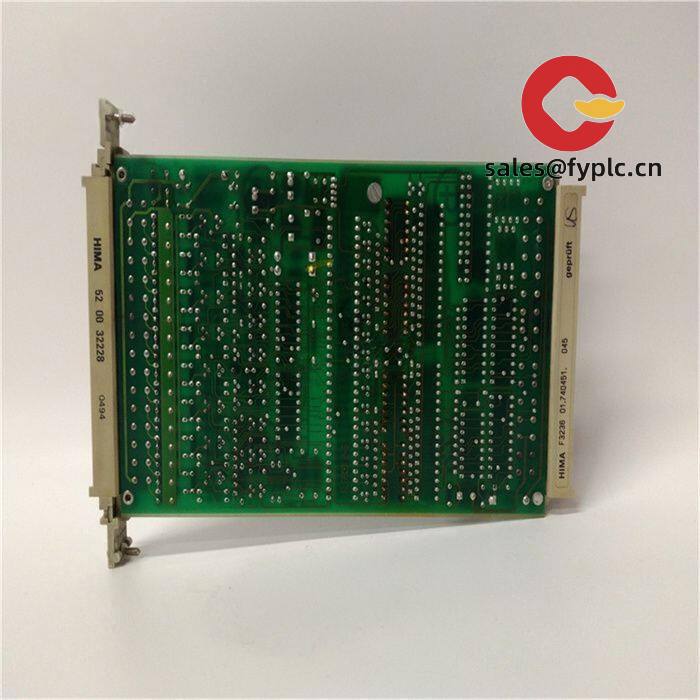

HIMA F6215 – High‑Precision 8‑Channel Analog Input Module for Safety‑Critical Monitoring

The HIMA F6215 is designed for accurate, multi-channel analog signal acquisition in safety-related control systems. From my experience, it’s typically used where reliable 4–20 mA and voltage measurements feed into an SIS or high‑availability PLC, such as compressor protection, burner management, or ESD logic. One thing I appreciate is the combination of precision and channel diagnostics—it seems to be engineered to keep noisy field wiring from compromising your shutdown logic.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- 8 analog inputs – Consolidates multiple field signals to a single, compact module for cleaner cabinet layouts.

- High-precision acquisition – Stable measurements for 4–20 mA and common voltage ranges, helping reduce trip uncertainty.

- Channel diagnostics – Open‑circuit or range fault detection in many cases, so technicians can pinpoint wiring issues faster.

- Galvanic isolation – Input-to-system isolation helps cut ground loops and noise carried in from long cable runs.

- Backplane integration – Seamless communication with the HIMA system bus; no front‑side configuration port required in typical setups.

- Safety system ready – Suited for use in SIL-rated HIMA architectures when applied per the certified safety manual.

- Compact 1-slot format – Frees panel space and simplifies spares management across identical I/O cards.

Technical Specifications

| Brand / Model | HIMA F6215 |

| HS Code | 8537.10 (Programmable control panels and modules) |

| Power Requirements | Backplane-powered; nominal 24 VDC system supply (typical for HIMA racks) |

| Dimensions & Weight | Compact 1-slot plug‑in module for the designated HIMA I/O rack |

| Operating Temperature | 0 to +60 °C (typical; confirm per system manual) |

| Signal Input/Output Types | 8× analog inputs; commonly supports 4–20 mA and standard voltage ranges; channel-to-bus isolation |

| Communication Interfaces | System backplane bus (no external comms on the front in most cases) |

| Installation Method | Plug‑in card mounted on the compatible HIMA safety system base rack |

Application Fields

You might notice that the F6215 shows up where analog accuracy and functional safety intersect:

- Emergency Shutdown (ESD) systems collecting process pressure, temperature, and level signals

- Burner Management and boiler protection with tight trip tolerances

- Compressor and turbine monitoring—vibration, lube oil temperature, and seal gas pressures

- Tank farms (overfill prevention), pipelines, chemical dosing skids

- Refining, petrochemical, pharma, power generation, and specialty chemicals

Advantages & Value

- Reliability – Proven HIMA architecture and isolation design reduce nuisance trips and intermittent faults.

- Compatibility – Works within the HIMA safety platform, simplifying integration with existing racks and CPUs.

- Lifecycle savings – Standardized 8‑channel count and diagnostics can cut spare parts and troubleshooting time.

- Technical support – Documentation and parameterization practices familiar to most HIMA-certified integrators.

Installation & Maintenance

- Panel/cabinet – Install in a clean, ventilated enclosure; allow airflow around the rack; maintain recommended ambient temperature.

- Wiring – Use shielded twisted pairs for analog loops; ground shields at one end; separate from high‑voltage and VFD cables.

- Power & grounding – Stable 24 VDC system supply with proper earth bonding to minimize noise.

- Commissioning – Verify channel scaling, range, and alarm limits; simulate open/short conditions to test diagnostics.

- Routine maintenance – Periodic terminal re‑torque, dust removal, and functional proof testing per your SIS plan; firmware/config updates as approved by your MOC.

- Spare strategy – Keeping one spare F6215 on hand typically shortens MTTR for critical loops.

Quality & Certifications

- CE marked; RoHS compliant (typical for HIMA modules)

- SIL 3 capable when applied per IEC 61508 within the certified HIMA system architecture (TÜV assessed in many cases)

- Manufacturer quality system aligned with ISO 9001 practices

- Warranty: 365 days (seller warranty)

Related and Supporting Components

- HIMA system CPU/controller module (for the corresponding rack family)

- HIMA I/O base rack and terminal base for F6215 mounting

- Field barriers/isolators for hazardous areas where required (e.g., 4–20 mA loops in Zone/Division classified locations)

- HART modem or asset management integration if HART passthrough is implemented on your installation

“We swapped legacy AI cards for F6215 units on our ESD. The improved signal stability meant fewer nuisance alarms during startups.” — Maintenance Supervisor, petrochemical site

Notes: Specs can vary slightly by system family and firmware revision. If you share your existing rack type and signal ranges, we can verify exact compatibility and recommended part variants before shipping.

Reviews

There are no reviews yet.