Description

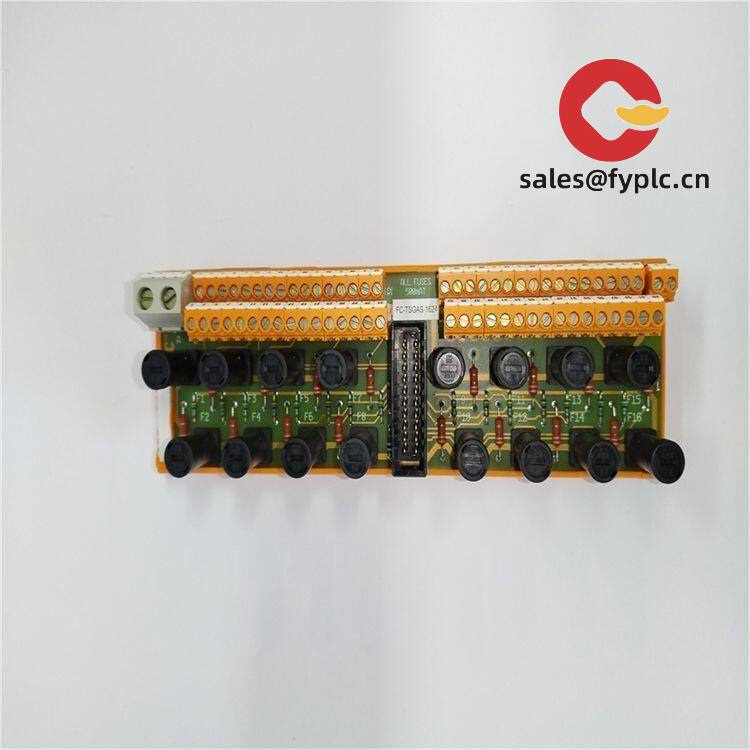

Foxboro FBM201D P0922YK – Analog Input Module for Reliable 4–20 mA Signal Acquisition

The Foxboro FBM201D (part number P0922YK) is an analog input module designed for stable, noise-resistant acquisition of process signals in distributed control systems. From my experience, it’s typically used where you need dependable 4–20 mA measurements from transmitters in process plants, and it integrates cleanly into existing Foxboro I/A Series architectures. You might notice that it keeps channels steady even in electrically noisy cabinets, which in many cases saves time during commissioning.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express Options: FedEx, UPS, DHL

- Packaging & Verification: Anti-static protected; each module visually inspected and power-tested before dispatch

Key Features

- 4–20 mA analog inputs: Suited for process transmitters (pressure, flow, level, temperature) with stable measurement under industrial conditions.

- HART pass-through support (revision-dependent): In many cases the FBM201D allows HART data pass-through for device diagnostics without interrupting the analog loop.

- Robust noise immunity: Designed for cabinets with VFDs and heavy equipment; typically maintains signal quality with proper grounding and shielding.

- Hot-swappable on the baseplate: Swap modules during maintenance windows without rewiring the terminal assembly, reducing downtime.

- Integrated diagnostics: Health/status LEDs and system-level diagnostics help pinpoint wiring or device issues faster.

- Tight system integration: Works within Foxboro I/A Series carriers/baseplates, simplifying expansion of existing nodes.

Technical Specifications

| Brand / Model | Foxboro FBM201D, Part No. P0922YK |

| HS Code | 8538.90 (Parts for industrial control/switchgear equipment) |

| Power Requirements | Powered from the Foxboro system baseplate/carrier (24 VDC nominal via backplane); no external supply to the module |

| Operating Temperature | 0 to 55°C (typical for FBM family; confirm per site standards) |

| Signal Input Types | Analog input, 4–20 mA transmitter loops; HART pass-through support on channels (depends on configuration and revision) |

| I/O Channel Count | Multiple analog input channels (commonly used for 8-channel configurations in this family) |

| Communication Interfaces | Backplane connection to the Foxboro control system; HART data tunneled via host tools when enabled |

| Installation Method | Plugs into standard Foxboro FBM baseplate/carrier with separate field termination assembly (TA) |

Application Fields

Plants that rely on stable analog loops typically choose FBM201D for:

- Oil & Gas – wellhead pressure, separator level, and pipeline instrumentation.

- Chemicals & Petrochem – reactor pressure, utility flow, cooling water control.

- Power Generation – boiler feedwater transmitters, condenser vacuum, balance-of-plant loops.

- Water & Wastewater – filter differential pressure, flow/level transmitters, dosing skids.

- Pharma & Food – CIP skids, jacketed vessels, and gentle process loops where uptime matters.

A maintenance lead at a midstream site told us their FBM201 modules “quieted down” erratic readings once the cabinet grounding and shield terminations were cleaned up—so the hardware seems pretty forgiving when the basics are right.

Advantages & Value

- Reliability in harsh panels: Good immunity and stable baselining reduce nuisance trips and callouts.

- Compatibility: Drop-in fit for Foxboro I/A Series nodes; no surprises with cabling or termination assemblies when matched correctly.

- Lifecycle savings: Hot-swap and diagnostic visibility typically cut downtime and troubleshooting hours.

- Support for HART: When enabled, you can pull device diagnostics without leaving the control room.

- Scalable spares strategy: Standard FBM form factor simplifies stocking and operator training.

Installation & Maintenance

- Cabinet & mounting: Install on the specified Foxboro baseplate/carrier within an industrial control cabinet; allow front clearance for module removal.

- Power & grounding: Use the system power from the carrier; maintain single-point grounding and consistent shield terminations to minimize noise.

- Wiring: Route 4–20 mA signals in twisted shielded pairs; separate from high-voltage or VFD cabling. Label channels clearly at the terminal assembly.

- Ventilation: Provide cabinet airflow; avoid locating near heat sources. Keep ambient within the stated operating range.

- Hot-swap practice: Place the channel or loop in a safe state before swapping; verify status LEDs post-insertion.

- Routine care: Periodically inspect terminals for corrosion, re-torque as needed, and verify loop calibration with a traceable source. Apply approved firmware/config updates during planned outages.

Supporting components you’ll typically pair with this module include the Foxboro baseplate/carrier, a matching field termination assembly (TA), and the system redundant power supply. If you’re standardizing spares, keeping one extra TA and a labeling kit tends to speed up loop checks.

Quality & Certifications

- Certifications: CE; UL/CSA for industrial control equipment in many configurations; RoHS compliance by revision (documentation available on request)

- Warranty: 12 months standard

- Traceability: Each module inspected and recorded by serial/part number prior to shipment

Reviews

There are no reviews yet.