Description

Bently Nevada 330130-045-01-CN – Flexible 3300 XL Extension Cable for Proximity Probe Systems

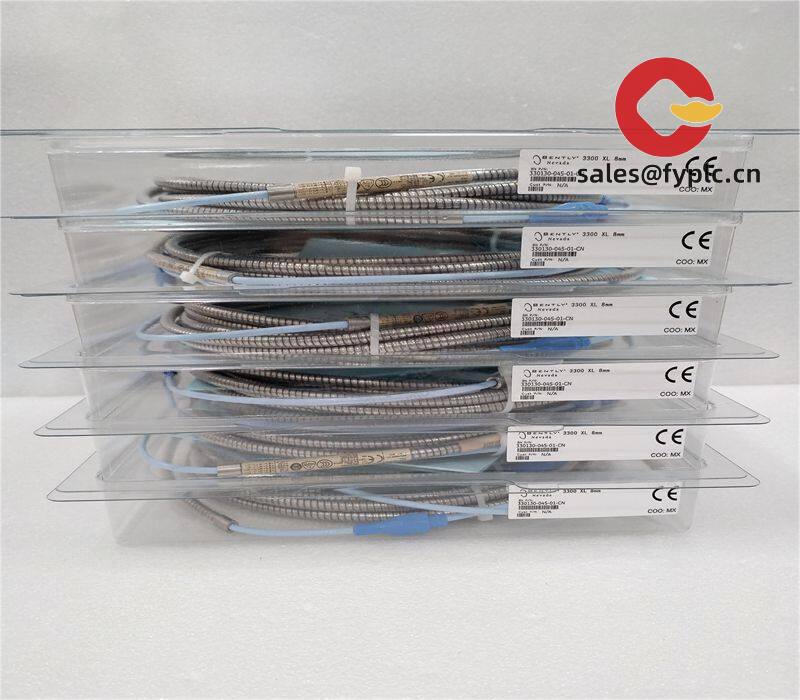

The Bently Nevada 330130-045-01-CN is a flexible extension cable designed for 3300 XL proximity transducer systems. From my experience, this “-045” variant is typically a 4.5 m cable, intended to pair with a 0.5 m probe cable to achieve a 5 m system length—one of the most common setups in turbines, compressors, and large motors. The “-01” denotes the standard connector configuration used across 3300 XL components, and the “-CN” suffix usually indicates a China-market labeling/compliance variant with identical function and performance to the global version.

You might notice that technicians favor the flexible (non-armored) version in cabinets and protected runs where easy routing and tight panel layouts matter. It simply connects between the probe and the 3300 XL Proximitor Sensor, maintaining the factory-matched transducer performance without introducing signal headaches.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Matched 3300 XL performance – Maintains system accuracy when used with compatible 3300 XL probes and Proximitor Sensors.

- 4.5 m flexible cable – Ideal for achieving a 5 m system length when paired with a 0.5 m probe cable.

- Standard 3300 XL connectors – Factory-terminated coax connectors for quick, reliable installations.

- Non-armored, easy routing – Suited for cabinet runs and protected conduits where bendability is preferred.

- High signal integrity – Designed to carry the proximity transducer RF signal with minimal loss or interference.

- CN regional variant – Typically indicates China-market labeling/compliance while keeping identical electrical characteristics.

Technical Specifications

| Brand / Model | Bently Nevada 330130-045-01-CN |

| HS Code | 8544.20 (Coaxial cable) |

| Cable Length / System Fit | 4.5 m extension; pairs with 0.5 m probe cable for 5 m total system length |

| Power Requirements | Not applicable (passive cable) |

| Signal Input/Output Types | Eddy-current proximity transducer RF/analog signal (probe ↔ Proximitor Sensor) |

| Communication Interfaces | None |

| Construction | Flexible, non-armored, factory-terminated coax |

| Operating Temperature | Typically −51 to +121 °C (depends on jacket material) |

| Installation Method | Panel/cabinet or conduit routing; connect between probe and 3300 XL Proximitor Sensor; recommended bend radius ≥ 10× cable OD |

| Dimensions & Weight | Length 4.5 m; slim OD for easy routing (lightweight) |

Application Fields

Typically used in condition monitoring and protection systems across:

- Steam and gas turbines for shaft vibration and axial position

- Centrifugal compressors and expanders

- Critical pumps, fans, and motors in refining, petrochemical, and power plants

- OEM skid packages where 5 m system length is standard

A maintenance lead at a gas processing site told us the 4.5 m flexible lead “made panel work less fussy—no extra loops, no signal drift, and it just fits the 5 m spec every time.”

Advantages & Value

- Reliability – Matched to 3300 XL system electronics, which helps avoid calibration surprises during commissioning.

- Compatibility – Drop-in fit with 3300 XL probes and Proximitor Sensors used on 5 m systems.

- Lower installation effort – Flexible jacket and factory connectors reduce routing time in tight cabinets.

- Procurement confidence – Standardized length coding (-045) simplifies BOM accuracy and spares alignment.

- Support – We can help verify the correct cable-to-probe combination so the total system length is right the first time.

Installation & Maintenance

- Environment – Route inside control cabinets or protected conduit; avoid sharp edges and hot exhaust paths.

- Wiring – Maintain clean coax runs; do not mix with high-voltage cables; keep spare length to gentle service loops.

- Bend radius – Typically ≥ 10× cable OD to preserve signal integrity and avoid conductor fatigue.

- Grounding/EMI – Keep away from VFD outputs and strong EMI sources; retain factory shielding continuity at connectors.

- Routine checks – Inspect connectors for tightness, jacket for abrasion, and verify transducer gaps during scheduled outages. The cable itself doesn’t require calibration, but system verification is recommended.

Quality & Certifications

- CE and RoHS conformity are typical for this family; production under ISO 9001 quality systems.

- Manufacturer warranty terms vary by region and channel; commonly 1 year on new items.

- Our supply warranty: 365 days, with prompt replacement/support if any quality issues arise.

Related/Supporting Components

- 3300 XL Proximity Probes (5 mm / 8 mm)

- 3300 XL Proximitor Sensors

- Mounting hardware, brackets, and junction boxes for proximity transducer systems

If you’re standardizing on 5 m systems or refreshing spares, the 330130-045-01-CN is, in many cases, the cleanest way to keep installations consistent without reworking your wiring practices.

Reviews

There are no reviews yet.