Description

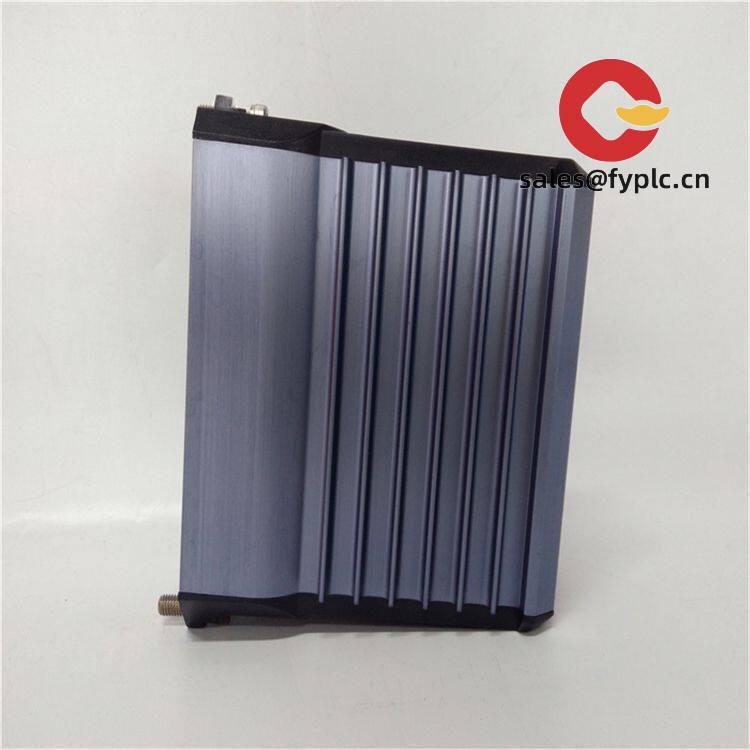

Foxboro FBM212 P0914XL Interface Module – Stable I/A Series I/O interface for demanding process plants

The Foxboro FBM212 (part code P0914XL) is part of the well-regarded I/A Series 200 I/O family. From my experience, it’s the kind of interface module you pick when you need consistent signal handling, easy maintenance, and straightforward integration with existing Foxboro baseplates and termination assemblies. You might notice that it drops into a cabinet without drama, supports hot‑swap, and typically works in redundant pairs for higher availability.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: In stock typically ships in 1 week; no more than 1 month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

- Pre‑shipment checks: Visual inspection and power‑up test when applicable

Key Features

- 200 Series baseplate compatible: Plugs directly into Foxboro I/A Series baseplates with field terminations via TAs.

- Hot‑swappable module design: In most cases you can replace the module online, minimizing process downtime.

- Redundancy ready: Supports paired operation for higher availability where the process can’t afford a stop.

- Robust electrical isolation: Channel-to-bus isolation helps cut down on ground loops and nuisance trips.

- Status and diagnostics: Front LEDs and built‑in diagnostics typically speed up troubleshooting.

- Industry‑grade environmental ratings: Designed for control cabinets in harsh, high‑uptime plants.

- Flexible signal handling: When paired with the right termination assembly, it’s commonly used with 24 Vdc discrete signals or analog loops.

Technical Specifications

| Brand / Model | Foxboro FBM212 (P0914XL) |

| HS Code (HS‑6) | 8537.10 – Boards, panels, consoles for electric control, for voltage ≤ 1000 V |

| Power Requirements | 24 VDC nominal supplied via baseplate; consumption typically < 5 W |

| Dimensions & Weight | Approx. 142 × 45 × 132 mm; ~0.45 kg (module only) |

| Operating Temperature | 0 to 60 °C; 5–95% RH non‑condensing (typical for 200 Series) |

| Signal Input/Output Types | Varies by termination assembly; commonly used with 24 Vdc discrete I/O or 4–20 mA analog loops in many cases |

| Communication Interfaces | Modulebus connection to Foxboro controller; field wiring via TA (Termination Assembly) |

| Installation Method | Plugs into 200 Series baseplate; field terminations on TA; supports redundant pairing |

Application Fields

The FBM212 is typically deployed in process control cabinets across refining, petrochemicals, chemicals, power generation, water/wastewater, pulp & paper, and food & beverage. It’s a solid fit when you need stable, noise‑resistant signal interfacing into an I/A Series controller, especially where hot‑swap and redundancy matter. One plant engineer told me it “just kept running through high electrical noise during startup,” which seems to be consistent with what we see in brownfield upgrades.

Advantages & Value

- Reliability: Industrial‑grade isolation and diagnostics reduce nuisance trips and unplanned outages.

- Compatibility: Works with Foxboro 200 Series baseplates and TAs, easing migrations and spares management.

- Lifecycle savings: Hot‑swap capability and clear front LEDs help shorten maintenance windows.

- Expandable: Redundancy and modular channel scaling support phased expansions without cabinet redesign.

- Support readiness: We can provide test reports and packaging photos upon request, which helps with site acceptance.

Installation & Maintenance

- Cabinet standards: Mount on a rigid 19‑inch rack or panel with Foxboro baseplates. Keep 50 mm clearance for airflow where possible.

- Power & grounding: Use clean 24 VDC and a solid single‑point ground scheme to minimize noise. Shield field cables as recommended.

- Wiring: Route high‑voltage and high‑current cables away from low‑level signal runs. Keep terminations tight on the TA.

- Safety: De‑energize field circuits before inserting or removing modules. Follow site lockout/tagout procedures.

- Routine maintenance: Inspect connectors quarterly, vacuum dust (no solvents), and review diagnostics. Firmware/config updates should follow MOC procedures.

- Spares strategy: In many cases, plants keep at least one FBM212 spare per cabinet section to reduce MTTR.

Quality & Certifications

- Certifications: CE and UL/CSA markings are typical for the 200 Series. RoHS compliance may apply by revision.

- Standards: Designed for control cabinet use; commonly suitable for Class I, Div 2/Zone 2 environments depending on specific revision and installation.

- Warranty: 365‑day warranty from shipment date (module replacement or repair, subject to standard terms).

Reviews

There are no reviews yet.