Description

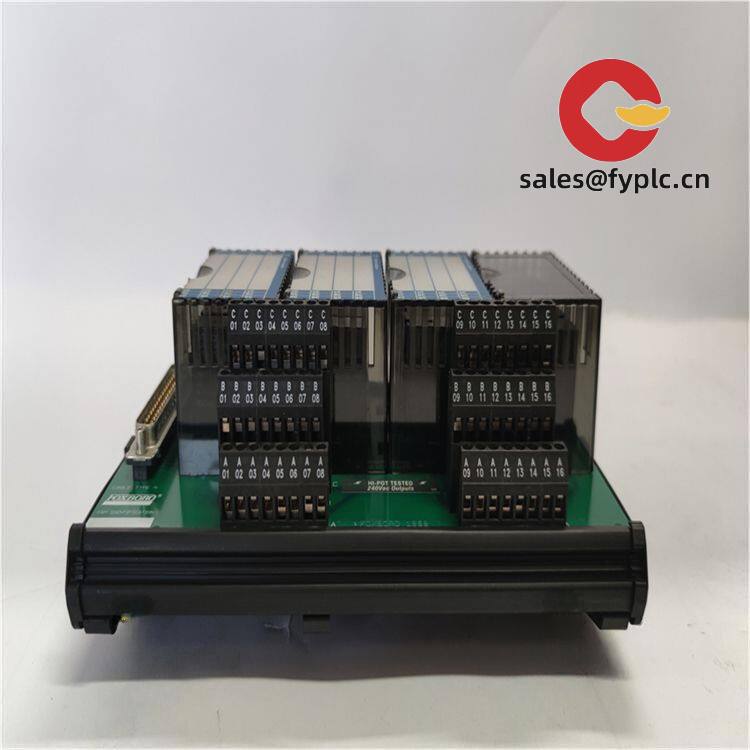

Foxboro FBM217 RH916XZ Discrete Input Interface Module – Reliable Digital Signal Acquisition for Foxboro DCS

The Foxboro FBM217 RH916XZ is a discrete input interface module from the proven 200 Series FBM family, designed to capture on/off status signals from the field and present them to your Foxboro DCS with stable, low-latency updates. From my experience, plants choose the FBM217 when they need solid digital input handling for limit switches, proximity sensors, relay contacts, and MCC status points—without re-engineering their existing cabinets. It seems to be a straightforward drop-in when expanding legacy I/A Series nodes or modern EcoStruxure Foxboro DCS architectures.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Discrete input interface for on/off signals – Ideal for limit switches, pushbuttons, relay contacts, and proximity sensors.

- High channel density (submodel dependent) – Typically used to consolidate many digital points in one FBM footprint, reducing cabinet space.

- Robust isolation and noise immunity – Helps cut down on nuisance trips in electrically noisy MCC rooms or compressor areas.

- System-ready with Foxboro DCS – Integrates natively with 200 Series baseplates and Foxboro controllers for quick commissioning.

- Diagnostics and status LEDs – You might notice channel health and state at a glance, which speeds up troubleshooting.

- Flexible field termination – Works with standard Termination Assemblies (TAs) to match your wiring style and cabinet standards.

- Supports redundancy strategies – In many cases, pairing modules on the baseplate enables higher availability.

Technical Specifications

| Brand / Model | Foxboro FBM217 RH916XZ (200 Series FBM) |

| Product Type | Discrete Input Interface Module for Foxboro DCS |

| HS Code | 853890 (Parts for electrical control apparatus) |

| Power Requirements | 24 Vdc supplied via the 200 Series baseplate; typical consumption low (<5 W) |

| Signal Input Types | Discrete (digital) inputs; supports dry-contact or voltage-type status signals (range depends on sub-variant and TA) |

| Communication Interfaces | FBM fieldbus connection to 200 Series baseplate; engineered within Foxboro DCS |

| Installation Method | Plugs into 200 Series baseplate; field wiring via Termination Assembly (TA); cabinet/DIN-rail mounting via baseplate |

| Operating Temperature | 0 to 50°C typical control cabinet environment |

Application Fields

You’ll typically see the FBM217 handling status and interlocks across continuous and hybrid process plants. A few practical examples:

- Valve open/closed limit switches in refining, petrochemical, and gas processing units

- Pump and fan run/stop status from MCCs in power, mining, and water treatment

- Conveyor photoeye and proximity sensor inputs in bulk material handling

- Alarm contacts, ESD permissives, and utility skid signals in pharmaceuticals and food & beverage (non-safety applications)

Advantages & Value

- Fit-form-function for Foxboro DCS – Minimizes rework and keeps your cabinet layout intact.

- Reduced downtime risk – Proven 200 Series topology and stable firmware cut integration time.

- Cost-effective expansion – High channel density and standard TAs simplify wiring and save on marshalling.

- Lifecycle confidence – Widely installed base and strong parts ecosystem enhance maintainability.

- Technical assistance – From my experience, engineering moves faster when the I/O module is native to the control system.

Installation & Maintenance

- Cabinet environment – Mount on a 200 Series baseplate in a ventilated, clean control cabinet; maintain ambient 0–50°C and avoid condensation.

- Wiring – Use the appropriate TA for your signal type (dry contact or voltage-type). Keep shield terminations consistent and segregate high-voltage cabling.

- Grounding – Bond the cabinet and baseplate ground; follow plant earthing standards to reduce noise and transients.

- Redundancy – Where high availability is required, consider redundant FBM pairs and dual power feeds on the baseplate.

- Routine checks – Inspect LEDs and diagnostics during rounds, verify channel state changes, clean dust from vents, and keep firmware revisions aligned with your site standard.

Quality & Certifications

- Manufacturer quality systems typically aligned with ISO practices

- Common industrial approvals such as CE and UL are generally available for Foxboro 200 Series modules

- RoHS compliance for many modern production units (documentation on request)

- Sales warranty: 365 days as stated above

Compatible/Supporting Components

- 200 Series Baseplates – Required for power and backplane communications; available in several slot counts.

- Termination Assemblies (TAs) – Match your field wiring style (screw, cage-clamp, or pre-wired harness) and signal type.

- Controller Nodes – Works within Foxboro DCS architectures (e.g., FCP-based controllers) for engineering and diagnostics.

- Shielded Field Cables – Recommended for sensor runs in high-EMI areas like MCC rooms.

If you’d like, share the exact input voltage type and channel count required for your panel; we’ll confirm the appropriate FBM217 sub-variant and TA pairing, then lock in the delivery window.

Reviews

There are no reviews yet.