Description

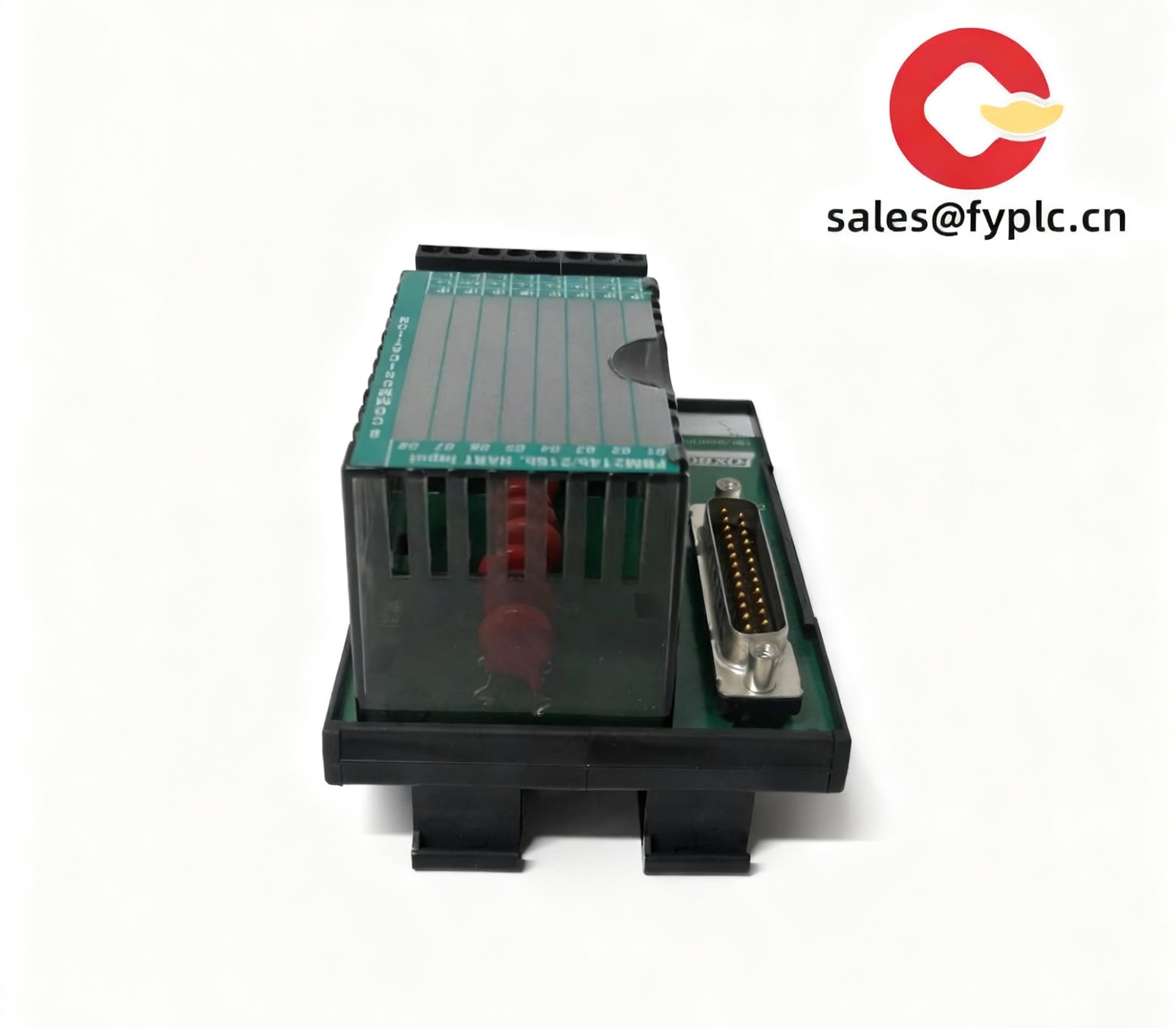

Foxboro P0924JH Compact Power Supply – Stable backplane power for Foxboro Compact/200 Series I/O

The Foxboro P0924JH Compact Power Supply is designed to feed regulated DC power to Foxboro compact baseplates and I/O modules, keeping your control nodes running consistently. From my experience with Foxboro I/A Series and Compact/200 Series installations, this power unit is typically used where cabinet space is tight, redundancy is expected, and downtime simply isn’t acceptable. You might notice that it emphasizes clean, low-noise power for FBM/Compact I/O rails, which—in many cases—translates to fewer nuisance trips and more predictable module life.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Compact, baseplate-ready form – Fits Foxboro compact baseplates to power FBM/Compact I/O without consuming extra cabinet space.

- Regulated low-noise output – Provides stable backplane power that helps reduce I/O error rates and improves module reliability.

- Redundancy-friendly design – Commonly deployed as a redundant pair; power sharing and switchover are smooth in most cases.

- Status indication – Front indicators make it easy to confirm power health during commissioning or quick checks.

- Industrial temperature range – Suitable for typical process control enclosures with consistent performance across standard ambient conditions.

- Simple wiring – 24 VDC feed terminals and direct backplane coupling keep installation fast and tidy.

Technical Specifications

| Brand / Model | Foxboro / P0924JH (Compact Power Supply) |

| HS Code | 8504.40 (Static converters, power supply units) |

| Power Requirements | Input: 24 VDC nominal (typically 18–32 VDC); Output: regulated backplane supply for Compact/FBM I/O; Power capacity: up to ~50 W typical |

| Dimensions & Weight | Approx. 130 × 50 × 120 mm; approx. 0.55 kg (module-only, varies slightly by revision) |

| Operating Temperature | 0°C to +60°C (typical control cabinet conditions) |

| Signal Input/Output Types | Power input: 24 VDC terminals; Power distribution: internal to Foxboro compact backplane (no external signal I/O) |

| Communication Interfaces | None (power-only module; front status indicators) |

| Installation Method | Mounts to Foxboro compact baseplate in a control cabinet; supports redundant pairing where required |

Application Fields

The P0924JH is typically found in Foxboro DCS nodes where compact I/O and FBM modules are installed. It suits:

- Oil & Gas – compact wellhead RTU panels or ESD interface cabinets needing redundant low-noise power.

- Chemical & Petrochemical – high channel-density I/O marshalling with strict uptime targets.

- Power Generation – turbine auxiliary systems and balance-of-plant skids where cabinet depth is limited.

- Water & Wastewater – remote stations powered by 24 VDC with clean backplane supply to I/O.

- Pharma & Food – clean-room cabinets where stable electronics power reduces batch interruptions.

“We paired two P0924JH units on a compact baseplate to support ~40 I/O points; switchover was seamless during a DC supply changeover.” — Maintenance Supervisor, specialty chemicals

Advantages & Value

- Reliability – Clean, regulated power for FBM/Compact I/O helps cut module resets and intermittent faults.

- Compatibility – Designed for Foxboro compact baseplates, so wiring and mounting are straightforward.

- Redundancy options – Dual-supply configurations reduce risk during maintenance and DC source transfers.

- Cost control – Compact footprint lowers cabinet size; less heat typically means fewer cooling upgrades.

- Supportability – Clear status indication and simple DC feed simplify troubleshooting and spares stocking.

Installation & Maintenance

- Cabinet & mounting – Install on the intended Foxboro compact baseplate inside a clean, ventilated control cabinet. Maintain 25–50 mm free air space around the module where possible.

- Wiring – Feed with a stable 24 VDC source (sized per load, with proper fusing). Use correctly sized conductors and tighten terminals to the recommended torque.

- Redundancy – For critical nodes, deploy two P0924JH units with dual DC feeds from independent breakers. Verify load sharing and switchover behavior during FAT/SAT.

- Grounding – Bond cabinet and backplane grounds to plant earth to minimize noise coupling into I/O circuits.

- Routine checks – Quarterly visual inspection for connector looseness, dust buildup, and LED status. Keep vents clean; avoid corrosive atmospheres.

- Firmware – No user firmware for the power module; maintenance is largely preventative and electrical.

Quality & Certifications

- CE compliant for industrial environments (EMC and safety)

- UL/CSA recognized components (typical for Foxboro modules)

- RoHS compliance for hazardous substances (where applicable)

- Manufacturer’s standard warranty applies; our supplied units include a 365-day warranty

Supporting Components & Typical Pairings

- Foxboro compact baseplates for FBM/Compact I/O (redundant-ready)

- 24 VDC industrial power feeders and dual-channel DC UPS for redundancy

- Foxboro FBM/Compact I/O modules used in process measurement and final control

Reviews

There are no reviews yet.