Description

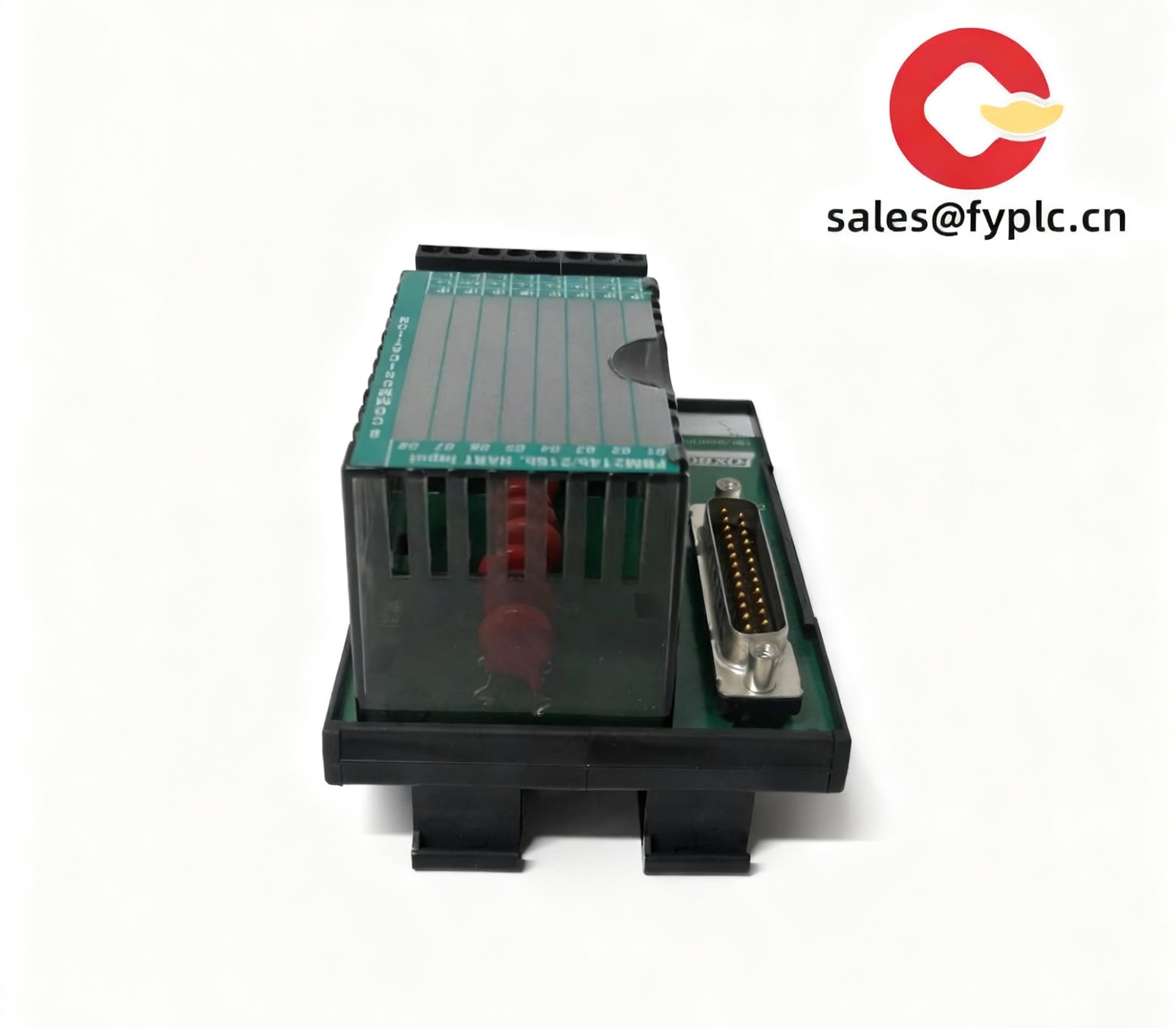

FOXBORO RH916XG Input Module – Multi‑Channel Analog Input for I/A Series DCS

The FOXBORO RH916XG is an input module designed for I/A Series distributed control systems, typically used where stable, multi‑channel analog signal acquisition is required. From my experience, it fits well in modernization projects that keep the existing Foxboro infrastructure while adding reliable, HART‑capable analog inputs. You might notice that it’s built for cabinet-mounted baseplate installations, with hot‑swap maintenance in many cases to reduce process downtime.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Multi‑channel analog input – Commonly deployed as a 16‑channel AI card, suitable for 4–20 mA loops.

- HART passthrough (typical) – In many systems, it supports HART data passthrough for device diagnostics and configuration without breaking the loop.

- Backplane powered – Draws power from the Foxboro baseplate, keeping panel wiring straightforward and tidy.

- Hot‑swap maintenance – Typically allows module replacement without shutting down the entire controller, minimizing process interruptions.

- Channel diagnostics – Open‑circuit and range diagnostics help maintenance teams find wiring faults faster.

- System integration – Communicates via the I/A Series backplane/fieldbus to the controller, preserving existing strategies and historian tags.

- Industrial environment ready – Designed for control cabinets with good thermal management; performs reliably across common plant temperature ranges.

Technical Specifications

| Brand / Model | FOXBORO RH916XG Input Module |

| HS Code | 8538.90 (Parts suitable for use with apparatus of 8535/8536/8537) |

| Power Requirements | Backplane powered via Foxboro baseplate; nominal 24 VDC system supply (module consumption typical of I/A Series AI cards) |

| Signal Input/Output Types | Analog Input, commonly 4–20 mA; HART passthrough in many configurations; per‑channel filtering and diagnostics |

| Channel Count | Typically 16 AI channels (model-dependent) |

| Communication Interfaces | I/A Series system backplane/fieldbus to controller; termination via Foxboro TA/baseplate assemblies |

| Operating Temperature | 0 to +60 °C (typical cabinet conditions for DCS I/O) |

| Dimensions & Weight | Module form factor; approx. 150 × 35 × 130 mm, ~0.5 kg (typical for Foxboro I/O modules) |

| Installation Method | Plugs into Foxboro baseplate; cabinet installation with terminal assembly (TA) wiring to field devices |

Application Fields

Plants that standardize on Foxboro I/A Series typically use the RH916XG wherever stable analog measurement is critical:

- Chemicals and petrochemicals – multi‑loop temperature and pressure inputs on reactors and heat exchangers.

- Oil & gas – separator skid signals, wellhead 4–20 mA transmitters, and HART diagnostics during commissioning.

- Power generation – boiler draft, feedwater flow, and balance‑of‑plant instrumentation.

- Water & wastewater – filtration differential pressure, turbidity transmitters, and dosing flow signals.

- Pulp & paper – digester control, stock consistency and steam header measurements.

A maintenance lead at a refinery told us the main benefit was routine hot‑swap without reterminating field wiring—“we pulled the old card, slotted the spare, and the loops came back in with the same scaling.”

Advantages & Value

- Reliability – Proven I/A Series architecture; stable operation in 24/7 process environments.

- Compatibility – Works within existing Foxboro baseplates and TAs, reducing retrofit complexity.

- Lifecycle savings – Keeps loops intact, limiting engineering hours and startup delays.

- Diagnostic depth – HART data access (where enabled) helps cut troubleshooting time.

- Support – Fast shipment windows for planned shutdowns and spares strategies.

Installation & Maintenance

- Cabinet & baseplate – Mount on the Foxboro baseplate in a ventilated control cabinet; keep at least 50 mm clearance for airflow.

- Power & grounding – Use the system’s 24 VDC supply via backplane; bond cabinet ground and maintain shield terminations per Foxboro TA guidance.

- Wiring – For 4–20 mA loops, use twisted shielded pairs; segregate from high‑voltage conductors to minimize noise.

- Redundancy – Where the system supports redundant fieldbus paths, verify both legs are healthy before hot‑swapping.

- Routine checks – Annual loop verification and transmitter calibration; review HART diagnostics for device health trends.

- Firmware/configuration – Back up point databases and card configuration before replacement or upgrades.

- Cleaning – Periodically remove dust with dry, oil‑free air; avoid liquids and aggressive solvents.

Quality & Certifications

- CE conformity for EMC and safety (typical for Foxboro I/A Series modules)

- UL/CSA listed (region dependent)

- RoHS compliance, where applicable to the specific build/revision

- Manufacturer warranty typically supported; our warranty coverage is 365 days

If you’re aligning spares or planning a migration, I can help match the RH916XG to the correct baseplate and terminal assembly options, and confirm channel type mapping vs. your current point database.

Reviews

There are no reviews yet.