Description

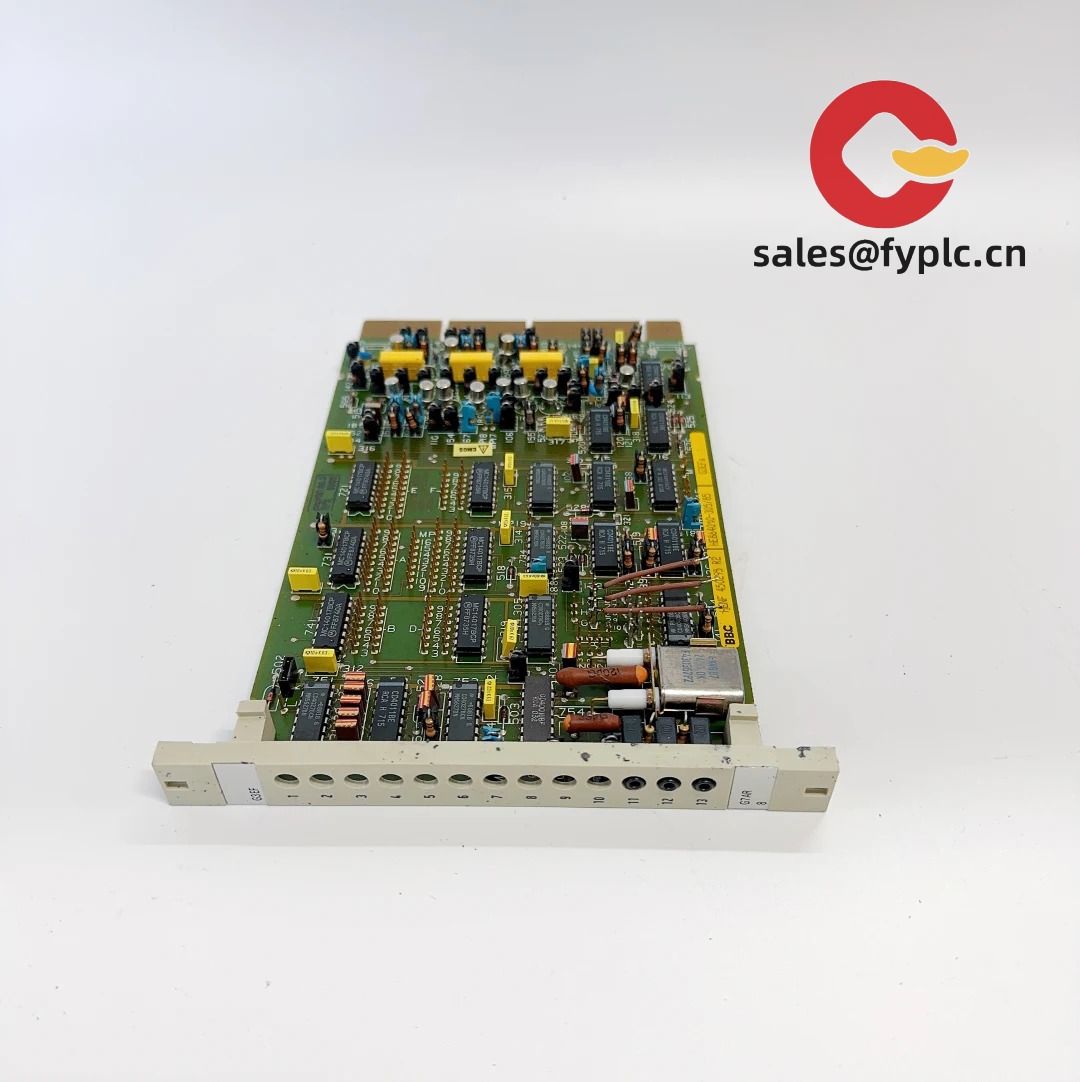

ABB G3EFa HENF450295R2 Controller – Compact CPU Module for Stable Plant Control and Fast Replacement

The ABB G3EFa HENF450295R2 is a controller module built for dependable, continuous operation in industrial environments. From my experience, it’s typically used as the primary control/logic unit inside ABB control cabinets or as a direct spare for maintaining legacy lines with minimal downtime. One thing I appreciate is how it slots into existing backplanes and works with remote I/O, so you don’t need to re-architect the whole panel just to get your plant back online. If you’re keeping an ABB-based DCS/PLC infrastructure running efficiently, this model seems to be a sensible, low-risk choice.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express couriers: FedEx, UPS, DHL

- Each unit is visually inspected and powered for basic functional verification before shipment, and packed for shock and ESD protection.

Key Features

- CPU controller module – Acts as the core logic/processing unit; coordinates remote I/O and field devices via system bus.

- Backplane integration – Designed to operate on the ABB system backplane for fast drop-in replacement in existing cabinets.

- 24 VDC control power – Typical low-voltage DC supply common in control panels, simplifying panel wiring and spares.

- No direct onboard I/O – I/O handled through compatible remote I/O modules; helps decouple CPU from channel count changes.

- Industrial temperature tolerance – Built for control rooms and shop-floor cabinets; in many cases runs stably in warm, ventilated enclosures.

- R2 hardware revision – Incremental refinement for better compatibility and reliability in field deployments.

Technical Specifications

| Brand / Model | ABB G3EFa HENF450295R2 |

| HS Code | 8537.10 (Programmable control equipment / control panels) |

| Power Requirements | 24 VDC nominal (typ. 18–32 VDC) |

| Operating Temperature | 0 to +55 °C (control cabinet application) |

| Signal I/O Types | No direct I/O; supports digital/analog I/O via compatible remote I/O modules |

| Communication Interfaces | System backplane bus; external fieldbus/ethernet via companion communication modules (per system design) |

| Installation Method | Cabinet mounting on system base/backplane; typically DIN-rail or rack base per ABB cabinet standard |

| Dimensions & Weight | Compact module form factor; suitable for 600–800 mm deep control cabinets |

Values reflect typical characteristics for this controller family; confirm exact parameters against your cabinet/base unit and revision R2 documentation.

Application Fields

This controller is commonly used in process automation and discrete manufacturing where uptime matters: chemical batching skids, utility sub-systems (boilers, chillers, air systems), packaging lines, and material handling cells. You might notice that maintenance teams often keep one on the shelf specifically to minimize downtime on ABB-based DCS/PLC cabinets. It pairs well with remote I/O islands for distributed control across large plants.

Advantages & Value

- Reliability: Built for 24/7 operation; from our installed base, nuisance resets are rare when powered with clean 24 VDC.

- Compatibility: Works with ABB system backplanes and remote I/O, reducing engineering effort in brownfield projects.

- Cost control: Drop-in replacement typically avoids re-cabling and revalidation, which translates into lower shutdown costs.

- Support: Access to configuration help, version checks, and pre-shipment testing to shorten commissioning times.

Installation & Maintenance

- Cabinet environment: Install in a closed control cabinet with adequate ventilation; avoid direct heat sources; maintain 0–55 °C ambient.

- Wiring: Use clean 24 VDC with proper grounding; segregate power and signal wiring; ensure correct keying on the backplane base.

- EMC practice: Keep shield drains and fieldbus cabling consistent with ABB grounding rules to reduce noise issues.

- Commissioning: Verify firmware/loader versions match project backups; document node addresses and network parameters before swap.

- Routine maintenance: Quarterly dust cleaning with ESD-safe methods, check terminal torque, review diagnostic logs; annual backup of application/parameters.

- Spare strategy: Keep one pre-configured spare on-site; in many cases this cuts recovery time from hours to minutes.

Quality & Certifications

- Conformity: CE-marked; RoHS-compliant where applicable; many units are UL Recognized for control equipment.

- Manufacturing: Produced to ISO-quality standards typical of ABB industrial controllers.

- Warranty: 365-day warranty coverage as stated above.

Reviews

There are no reviews yet.