Description

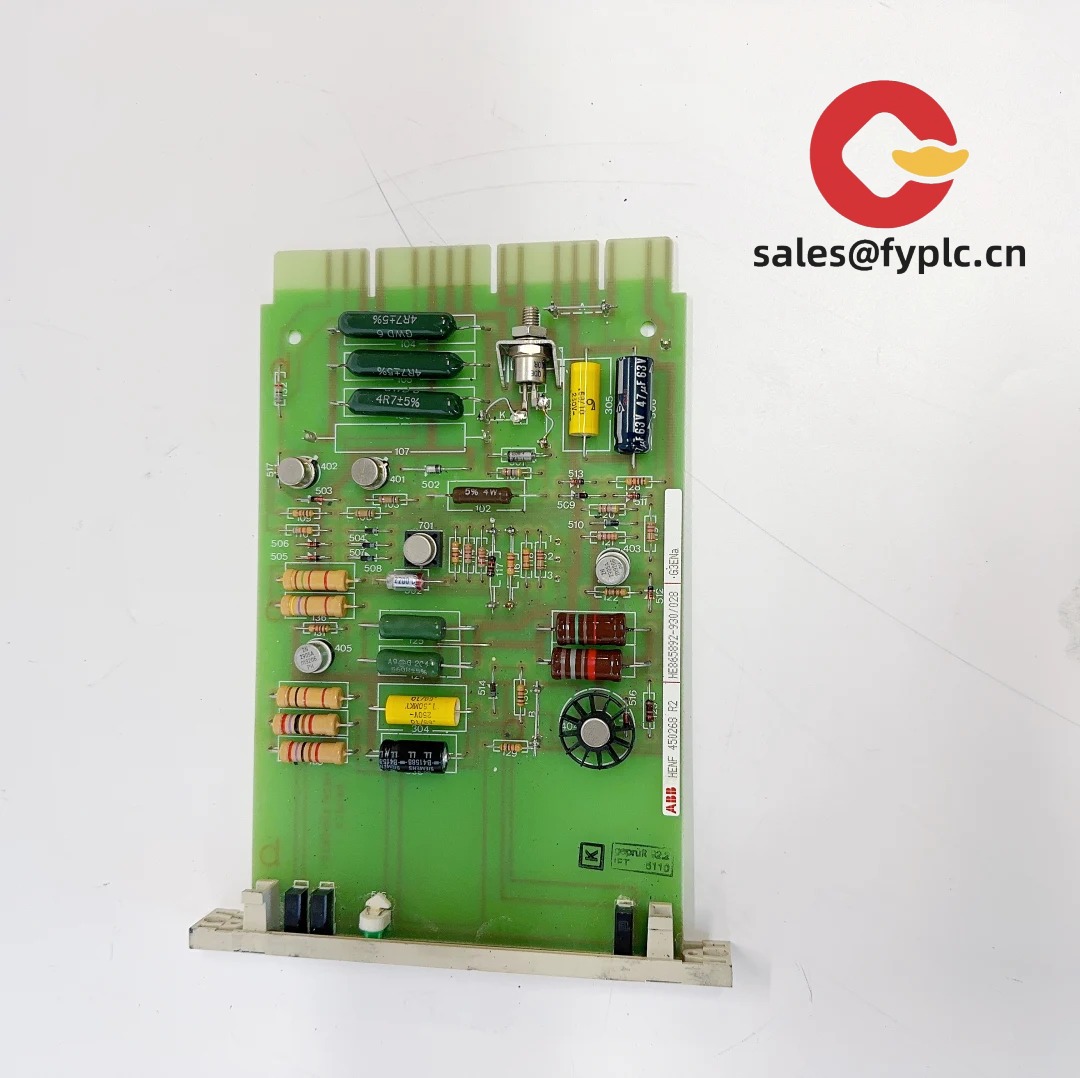

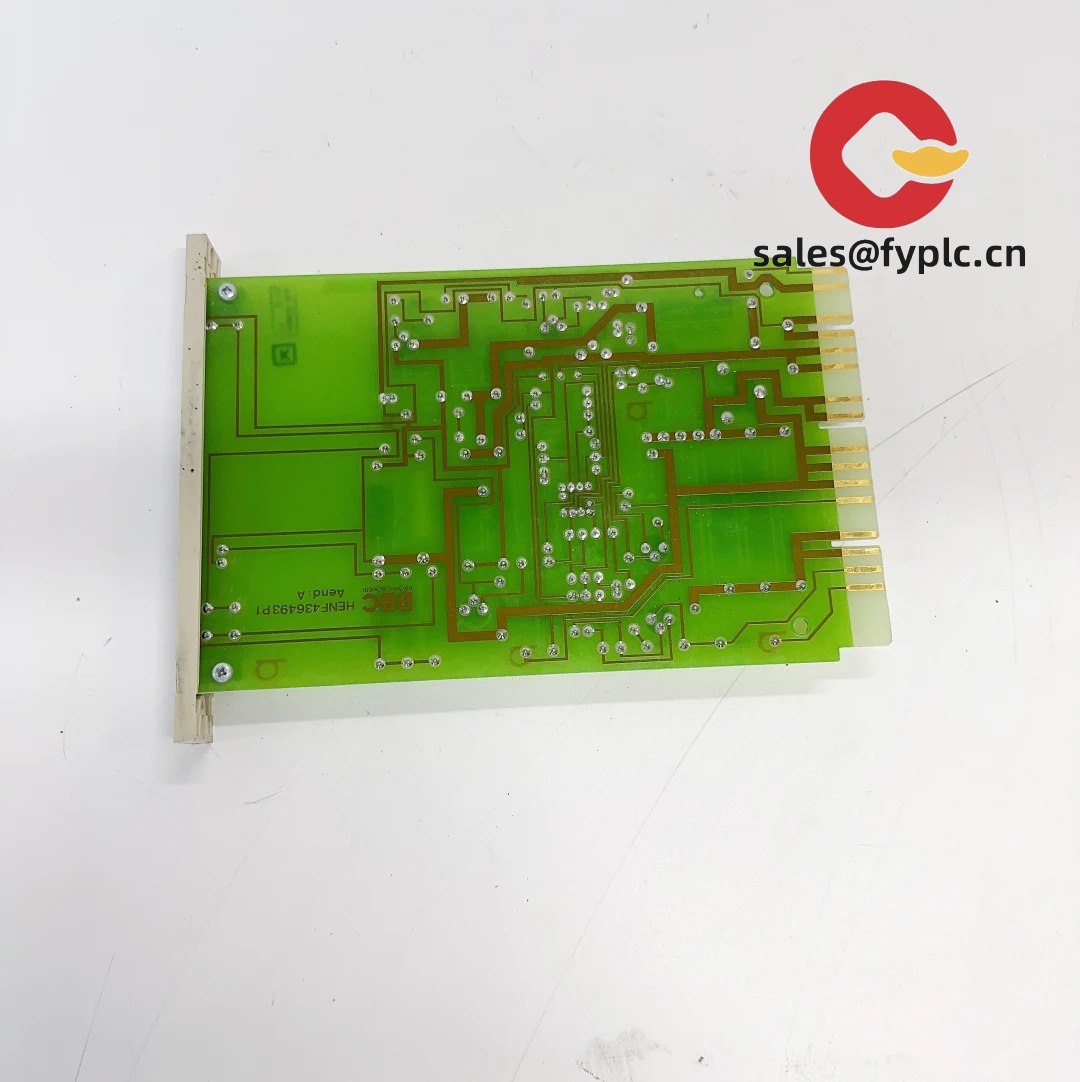

ABB G3ENa HENF450268R2 Controller – Ethernet-enabled control module for modernizing and maintaining plant systems

The ABB G3ENa HENF450268R2 appears to be a controller/communication module widely used as part of ABB control cabinets. From my experience, this type of module is chosen when you need stable Ethernet connectivity, predictable scan performance, and a drop‑in, plant‑proven form factor that works within existing backplanes. It typically serves as the “brains” or comms front end of an I/O rack—ideal for life‑cycle extensions, brownfield upgrades, or like‑for‑like replacements to get a line back up quickly.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Ethernet-centric design – Typically provides a 10/100 Mbps RJ45 port to interface with plant networks or engineering workstations.

- Backplane integration – Works within an ABB rack/backplane so field wiring and I/O modules don’t need to change during replacement.

- Deterministic control – Designed for stable scan cycles and predictable behavior in continuous process or discrete control.

- Diagnostics and status LEDs – You might notice at-a-glance health and comms indicators that speed up fault isolation.

- Firmware upgradability – In many cases the module supports field firmware updates via engineering tools, reducing downtime.

- Service-friendly form factor – Compact controller module that typically supports quick swap with minimal rework.

Technical Specifications

| Brand / Model | ABB / G3ENa HENF450268R2 |

| HS Code | 8537.10 (Programmable controllers; final classification may vary by country) |

| Power Requirements | 24 VDC nominal (typical for rack-mounted controller modules) |

| Operating Temperature | 0 to +55 °C (non‑condensing; typical controller-class range) |

| Communication Interfaces | 10/100 Mbps Ethernet (RJ45); backplane system bus |

| Signal I/O Types | No on-board field I/O; interfaces to discrete/analog I/O via backplane modules |

| Installation Method | Rack/backplane mounting in a control cabinet with 24 VDC supply and protective grounding |

Application Fields

This module suits plants where Ethernet connectivity and reliable controller behavior are mandatory:

- Refining, chemicals, and pharmaceuticals – controller replacement without disturbing validated I/O.

- Power generation and water treatment – steady-state control with simple remote diagnostics.

- Metals, mining, and cement – robust operation in cabinet‑protected harsh environments.

- Food & beverage or OEM test stands – quick commissioning with existing ABB backplanes.

A maintenance manager told us a recent swap took less than an hour—including IP setup and download—because the backplane and wiring were untouched. That kind of minimal disruption is, frankly, what most teams are looking for.

Advantages & Value

- Risk reduction – Keeps existing cabinets, I/O modules, and wiring intact to limit start-up risk.

- Cost control – Typically avoids re-engineering costs and lengthy shutdowns.

- Compatibility – Designed to cooperate with ABB backplanes and engineering tools used on site.

- Support and spares – Fast turnaround and a clear 365‑day warranty to stabilize maintenance planning.

Installation & Maintenance

- Cabinet environment – Install in a clean, ventilated cabinet; maintain ambient 0–55 °C and relative humidity below condensation.

- Power and grounding – Use a stable 24 VDC supply, protective earth, and proper cabinet bonding to reduce noise.

- Network wiring – Shielded industrial Ethernet (where applicable), managed switch ports, and labeled patch leads for traceability.

- ESD handling – Handle as an ESD‑sensitive device; de‑energize the rack before removal in most cases.

- Routine care – Annual dust cleaning, periodic log review, and planned firmware updates through approved engineering tools.

- Configuration management – Keep backups of configuration and project files; document IP settings and firmware revisions.

Quality & Certifications

- Typically CE-marked for EMC and safety; UL/cUL recognition may apply by variant and region.

- RoHS conformance depends on manufacturing revision; many units meet current directives.

- Supplied with a 365‑day warranty and functional testing prior to dispatch.

- Packed in anti‑static, shock‑protected packaging; traceable serials for lifecycle tracking.

Recommended Supporting Components

To streamline commissioning, many buyers also add:

- ABB backplane/terminal base compatible with the G3ENa footprint

- 24 VDC industrial power supply with surge protection

- Industrial Ethernet patch cords and a managed switch for VLAN/QoS where required

- Spare controller module kept on the shelf for critical lines

One thing I appreciate is how this module fits into existing ABB infrastructures with minimal fuss. If your goal is to stabilize an aging line or to standardize spares across sites, the G3ENa HENF450268R2 typically checks the right boxes without overcomplicating the project.

Reviews

There are no reviews yet.