Description

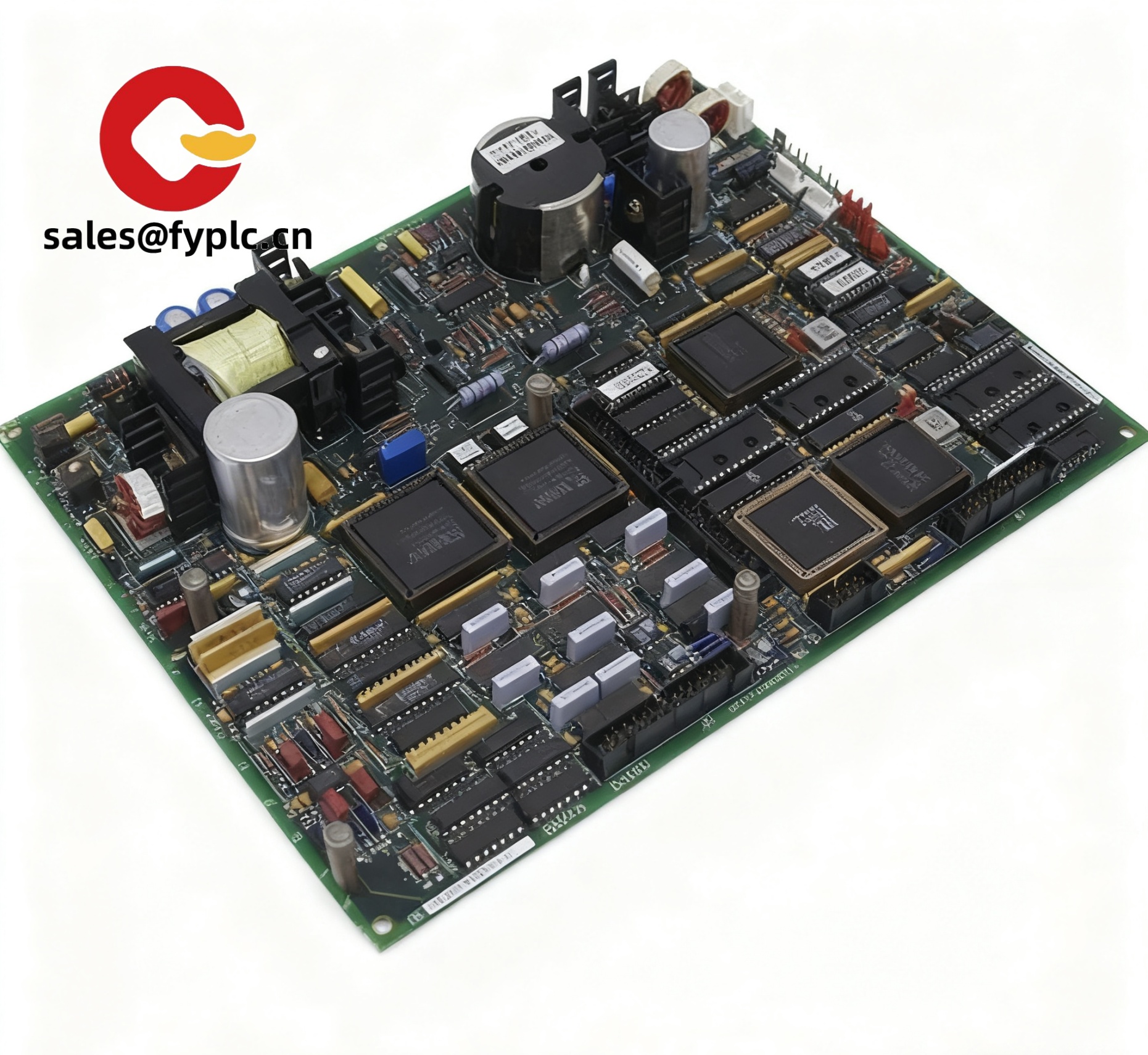

GE DS200TCPAG1AJD Turbine Control Processor Board – Core processing for Speedtronic Mark V control

The GE DS200TCPAG1AJD is a Turbine Control Processor Board used in Speedtronic Mark V systems. In many cases it acts as the primary logic engine inside the R/S/T cores, coordinating sequencing, start/stop logic, trips, and fast control routines. From my experience, plants choose this board when they need a dependable replacement for a Mark V CPU board without re-engineering the panel. You might notice that this “G1” series board with revision AJD slots straight into the existing backplane and works with the established I/O cards, which typically keeps upgrade downtime short.

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Turbine CPU core – Executes Mark V control, sequencing, protection, and monitoring logic.

- Backplane integration – Interfaces directly to the Mark V rack, minimizing field rewiring or configuration drift.

- Supports TMR architectures – Designed to operate within R/S/T redundant cores for high availability in critical turbine applications.

- On-board diagnostics – Status LEDs and internal self-tests help maintenance teams identify issues faster.

- Revision AJD – G1 hardware series with AJD revision level for improved stability and component lifecycle in many panels.

- Form-fit-function compatible – Typically drop-in for existing DS200TCPAG1x variants when matched to the site configuration and firmware level.

Technical Specifications

| Brand / Model | GE DS200TCPAG1AJD (Turbine Control Processor Board, Mark V) |

| HS Code | 8538.90.00 (Parts for industrial control apparatus) |

| System Compatibility | GE Speedtronic Mark V turbine control, typically in R/S/T cores |

| Power Requirements | Powered via Mark V backplane; logic 5 VDC rail (panel supply). Typical consumption is low (board-level), exact draw varies by revision/firmware. |

| Signal I/O Types | Internal backplane buses, discrete status lines, and inter-board control links (no direct field wiring on this board) |

| Communication Interfaces | Mark V rack backplane interfaces; diagnostic headers/LEDs for service checks |

| Operating Temperature | 0 to 50 °C inside a properly ventilated control cabinet (non-condensing) |

| Dimensions & Weight | Standard Mark V plug-in board; approximate board size near 330 × 280 mm; weight ~1.0–1.3 kg |

| Installation Method | Plug-in card; mounts to Mark V rack with backplane connectors and standoffs |

Application Fields

This board is typically used in:

- Gas and steam turbine generator sets in power plants

- Mechanical drive turbines for compressors and pumps in oil & gas

- Industrial cogeneration and process steam units

- Retrofit and life-extension projects where Mark V remains the control standard

A maintenance lead from a combined-cycle site summed it up simply: “Swapped in the DS200TCPAG1AJD during an outage; matched our R/S/T build, passed checks, and we were synced back on schedule.”

Advantages & Value

- Reliability in critical service – Built for the Mark V environment, with stable operation in TMR cores.

- Compatibility – Works with established Mark V I/O stacks and HMIs, helping avoid requalification of field wiring.

- Reduced downtime – Drop‑in form factor and known commissioning steps typically shorten maintenance windows.

- Lifecycle support – Availability of tested, warrantied units helps sustain legacy fleets without accelerated migration.

- Cost control – Replacing a single board is usually more economical than a full control system upgrade.

Installation & Maintenance

- Environment – Install in a clean, dry Mark V cabinet with adequate ventilation. Keep ambient 0–50 °C, non-condensing.

- ESD handling – Use wrist straps and ESD-safe procedures; handle by edges and standoffs only.

- Seating & connectors – Power down, inspect the backplane, then insert evenly to avoid bent pins. Verify all ribbon and edge connectors are latched.

- Grounding – Ensure panel grounding is intact; poor earth can cause nuisance trips or comms faults.

- Firmware & configuration – After installation, confirm the correct firmware/config for the unit and perform standard Mark V diagnostic checks before turbine restart.

- Routine care – Periodic dust removal with dry, oil-free air; visual inspection of capacitors and headers; review event/alarm logs; schedule checks during planned outages.

Quality & Certifications

- Manufactured to GE industrial quality standards; many units used in regulated power environments

- CE and UL typically addressed at the system/cabinet level; board-level compliance aligns with Mark V practice

- ISO 9001 quality management in the supply chain where applicable

- RoHS: legacy exemptions may apply due to original production era

- Warranty: 365 days replacement/repair coverage

Related & Supporting Components

For spares planning, sites commonly pair the DS200TCPAG1AJD with:

- GE DS200TCQAG1A – Control/analog interface board working alongside the CPU functions

- GE DS200TCDAH1A – Digital I/O interface within the Mark V core

- GE DS200TCCAG1A – Core communication/control card in many R/S/T racks

One thing I appreciate is how these boards, when kept as a matched set, tend to reduce commissioning surprises. If you share your existing part revisions, we can check cross-compatibility before shipment.

Reviews

There are no reviews yet.