Description

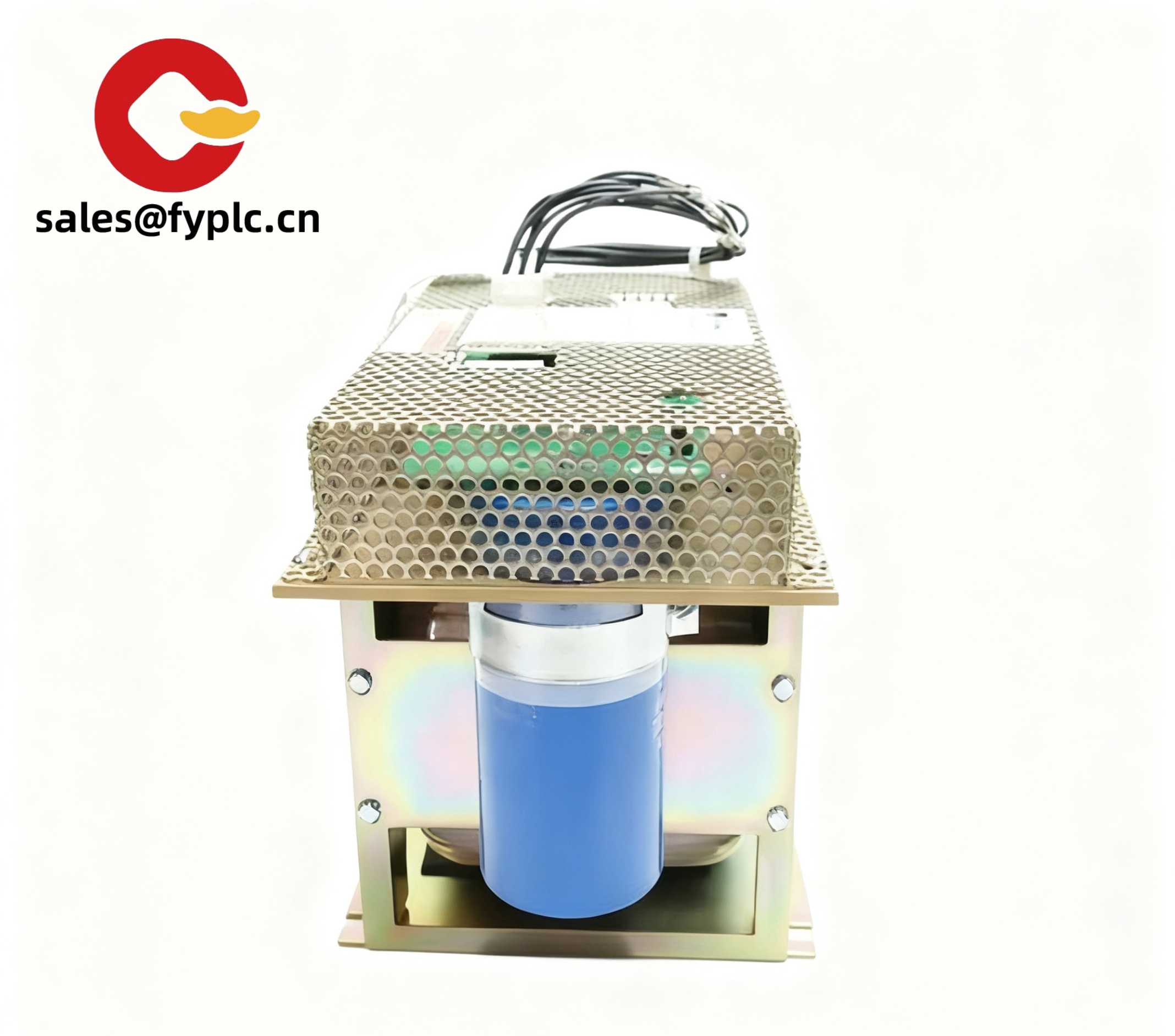

GE DS2020DACAG2 AC/DC Power Conversion Module – Stable control power for GE industrial cabinets

The GE DS2020DACAG2 is an AC/DC power conversion module designed to supply regulated low-voltage rails to GE control electronics. From my experience, this model is commonly used in GE drive and turbine-control cabinets where clean, stable DC power is critical for PLC/logic, I/O, and signal conditioning. You might notice that it’s engineered as a form/fit/function replacement, so maintenance teams can swap it quickly and keep systems online with minimal rework.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment method: 50% advance payment; full payment prior to delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- AC to DC conversion for control electronics: Provides regulated low-voltage rails typically used by logic and I/O circuits, helping stabilize sensitive loads.

- Noise-tolerant design: Built for electrically noisy industrial cabinets; in many cases it reduces ripple and interference that upset legacy boards.

- Form/fit/function replacement: Plug-in format matches GE cabinet hardware, keeping panel modifications to a minimum.

- Protection features: Over-current and over-voltage protection are typically included to safeguard downstream boards.

- Serviceable layout: Clear connectors and test points make commissioning and troubleshooting faster for field techs.

Technical Specifications

| Brand / Model | GE DS2020DACAG2 |

| HS Code | 8504.40 (Static converters – AC/DC power supply modules) |

| Power Requirements | AC input from cabinet control power (commonly 120/240 VAC, 50/60 Hz); DC outputs supply regulated low-voltage rails for logic and I/O |

| Operating Temperature | Typically 0 to +60°C (control cabinet environment) |

| Signal I/O Types | AC mains input; low-voltage DC outputs via backplane/card-edge connectors |

| Communication Interfaces | None (power conversion module) |

| Installation Method | Plug-in module for GE control cabinet backplane; retained with front hardware for secure mounting |

| Dimensions & Weight | Board-level DS2020-format module; compact, serviceable footprint for standard GE racks |

Application Fields

This module is typically deployed in GE industrial control cabinets found in power generation, medium-voltage drives, and excitation systems. I often see it supporting control electronics in:

- Gas/steam turbine control panels (legacy and retrofit cabinets)

- GE drive systems for metals, mining, paper, and water treatment

- Excitation and auxiliary power control (where stable DC rails are required)

- Process automation cabinets requiring dependable control power

One thing I appreciate is how it keeps older cabinets running without redesign. A maintenance lead at a combined-cycle plant told us: “Swapped the DS2020DACAG2 in under an hour and our logic rails stabilized immediately—no nuisance trips since.”

Advantages & Value

- Reliability: Clean, regulated DC rails help reduce intermittent faults across sensitive I/O cards.

- Compatibility: Designed for GE racks—usually no mechanical rework or rewiring beyond standard cabinet practices.

- Downtime reduction: Fast, plug-in replacement typically shortens outage windows for maintenance teams.

- Cost control: Extends the life of installed assets, delaying costly system-wide upgrades.

- Support: Application guidance and post-install follow-up so the module lands right the first time.

Installation & Maintenance

- Cabinet environment: Install in a clean, ventilated enclosure; keep ambient within 0–60°C and avoid condensation.

- Power wiring: Feed from an isolated control transformer (commonly 120/240 VAC, 50/60 Hz). Verify grounding and polarity before energizing.

- Mounting: Seat firmly in the backplane/card-edge connector and secure front fasteners to prevent vibration-induced loosening.

- Safety: De-energize cabinet, discharge stored energy, and follow lockout/tagout; handle the board using ESD precautions.

- Commissioning: Measure output rails with a calibrated DMM and confirm ripple is within your site’s acceptance criteria.

- Routine care: Quarterly dust removal, connector inspection, and check of cabinet fans/filters; re-torque terminal hardware if applicable.

Quality & Certifications

- Manufacturing typically aligned to ISO 9001 quality systems

- Meets CE/UL expectations for industrial control equipment where applicable

- RoHS applicability may vary by production year and region

- Manufacturer’s warranty: 365 days

Reviews

There are no reviews yet.