Description

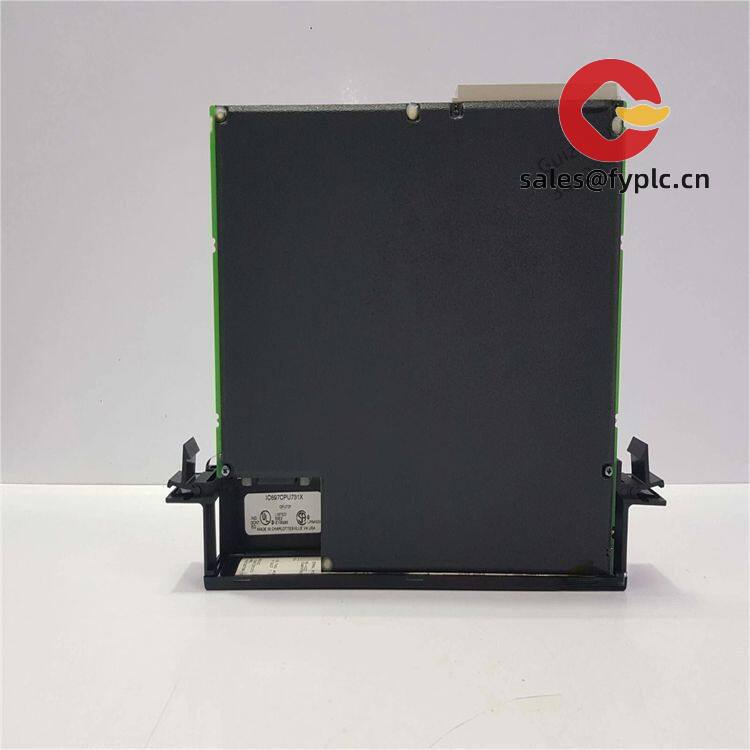

GE Fanuc IC697CPU731 – Series 90-70 CPU Module for high-performance PLC control

The GE Fanuc IC697CPU731 is a classic Series 90-70 CPU module designed for large, mission‑critical PLC applications. It slots into an IC697 rack and, in most cases, runs reliably for years with very little intervention. One thing I appreciate is how it balances mature, stable hardware with flexible expansion—Ethernet, Genius, and other networks can be added via standard IC697 communications modules. If you maintain legacy lines or need a drop‑in replacement to minimize downtime, this model typically makes the transition smooth with existing 90‑70 I/O and programming tools.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment, full payment prior to delivery

- Express: FedEx, UPS, DHL

Key Features

- Series 90‑70 platform – Works with the proven IC697 ecosystem, which many plants still rely on for continuous operation.

- Single‑slot CPU design – Saves rack space; installs in the designated CPU slot of the IC697 rack without special adapters.

- Programmer serial port – Typically provides an RS‑232 SNP/SNPX port for programming and diagnostics with Logicmaster 90‑70 or Proficy Machine Edition.

- Expandable communications – Add Ethernet TCP/IP, Genius, or other networks using standard IC697 communications modules, keeping the CPU core unchanged.

- Battery‑backed memory – Uses IC697 memory modules (IC697MEM7xx) for user program and data retention; ideal for brownouts or planned shutdowns.

- Industrial operating range – Designed for cabinet‑mounted use in typical factory environments where 0–60°C is common.

- Long‑term serviceability – Spare parts and accessories remain available in many markets; makes life easier for MRO teams.

Technical Specifications

| Brand / Model | GE Fanuc IC697CPU731 (Series 90‑70 CPU Module) |

| HS Code | 8537.10 (Programmable controllers / control panels) |

| Power Requirements | 5 VDC via IC697 backplane; typical draw around 1–2 A (model and configuration dependent) |

| Dimensions & Weight | Single‑slot IC697 form factor; standard 90‑70 rack height; approx. 0.6–0.9 kg |

| Operating Temperature | 0 to 60 °C (32 to 140 °F), 5–95% RH non‑condensing typical for Series 90‑70 |

| Signal I/O Types | No onboard discrete/analog I/O; uses IC697 I/O modules and remote I/O networks |

| Communication Interfaces | 1 × RS‑232 programmer port (SNP/SNPX); Ethernet, Genius, Profibus, and others via optional IC697 communication modules (e.g., IC697 Ethernet TCP/IP module) |

| Programming Software | Logicmaster 90‑70 (legacy) or Proficy Machine Edition, depending on plant standards |

| Memory Support | IC697MEM7xx modules for user program/data; battery‑backed RAM; nonvolatile options available per module type |

| Installation Method | Mounts in the CPU slot of an IC697 90‑70 rack; front‑access connectors for programmer port and memory module |

Application Fields

From my experience, the IC697CPU731 is typically chosen for lines that must stay compatible with existing 90‑70 infrastructure while keeping downtime minimal:

- Process industries (chemicals, batch, utilities) where stable scan cycles and proven logic are valued

- Discrete manufacturing and automotive cells using established IC697 I/O and Genius‑based remote I/O

- Power, water/wastewater plants with legacy redundancy or long validated configurations

- Material handling, steel, and heavy industry where ruggedized cabinet PLCs are standard

Advantages & Value

- Reliability – 90‑70 hardware has a reputation for long service life; many units run for decades with routine maintenance.

- Compatibility – Reuses your existing IC697 racks, I/O, and many communications modules; no need to redesign the whole panel.

- Cost control – A direct CPU swap typically reduces engineering hours, revalidation time, and training compared to full platform migrations.

- Supportability – Documentation, spare parts, and service know‑how are widely available; technicians are usually familiar with the toolchain.

Installation & Maintenance

- Cabinet & rack – Install in an IC697 rack within a ventilated, dry control cabinet. Maintain clearance for airflow and cable bend radius.

- Power & grounding – Use a properly sized IC697 power supply. Ensure protective earth and signal grounding are clean to avoid comms noise.

- Wiring – Use shielded cables for the programmer port and network modules; segregate low‑level signals from high‑voltage power wiring.

- Environment – Keep within 0–60 °C and non‑condensing humidity. Avoid corrosive atmospheres unless cabinet is rated accordingly.

- Memory & battery – Check the memory module part and battery status during PMs. Battery packs are usually replaced every 3–5 years.

- Firmware & backups – Verify CPU and comms module firmware levels are compatible. Keep off‑line backups of the user program and hardware configuration.

Quality & Certifications

- Manufacturer quality system: ISO 9001 (typical for GE Fanuc manufacturing)

- Product safety approvals: UL/cUL and CE (typical for Series 90‑70)

- RoHS: many original units pre‑date RoHS; compliance may vary by vintage and region

- Seller warranty: 365 days

Reviews

There are no reviews yet.