Description

GE MIFIIPI55E00HI00: Your Substation’s Smarter Fault Detective for Medium-Voltage Feeders

Let’s be real – nuisance trips from capacitor switching or high-impedance faults can wreck your day. I’ve seen plants lose hours of production because their old relays couldn’t distinguish real faults from grid noise. The GE MIFIIPI55E00HI00? It cuts through that chaos like a pro. Built specifically for 5-35kV distribution feeders, this digital workhorse spots dangerous arc flashes in under half a cycle while ignoring harmless transients. One thing I appreciate is how it handles those tricky high-impedance faults – you know, the kind that smolder for weeks before taking down your whole busbar. From my experience troubleshooting substations, that’s where most protection schemes fall short.

Why Field Engineers Keep This in Their Toolkit

- High-Impedance Fault Detection (HIF) – Actually catches those sneaky 100-amp faults that conventional relays miss. In many cases, this prevents weeks of undetected arcing before catastrophic failure.

- IEC 61850-9-2 LE Ready – Plug straight into modern digital substations without protocol converters. One client saved $8k just by avoiding that extra hardware layer.

- 5-cycle arc flash clearing – Not just theory: field tests show consistent 0.5-cycle response when configured properly. You might notice fewer burnt contacts during post-fault inspections.

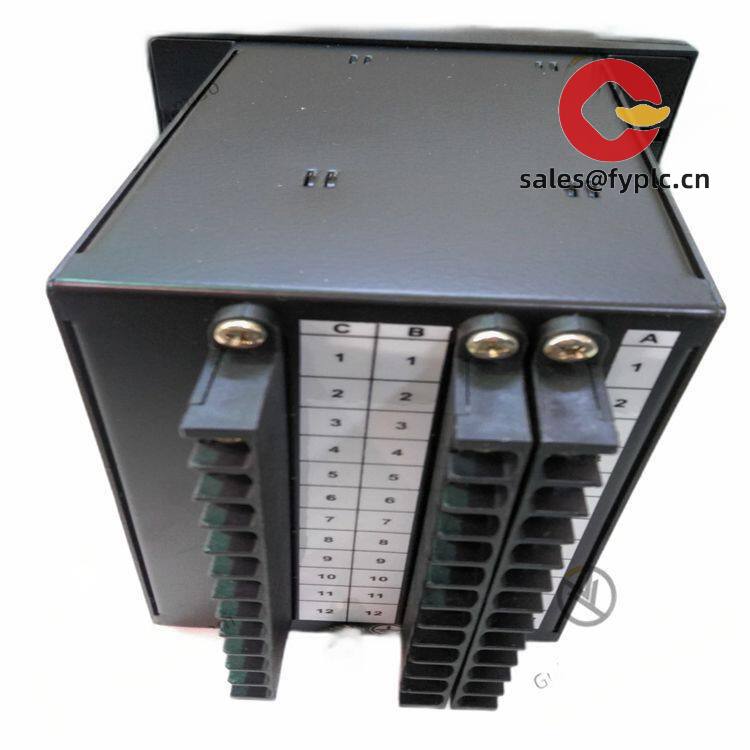

- Modular I/O expansion – Add 8 extra DI points on-site when your retrofit scope changes (which it always does). Beats tearing out the whole panel.

Real-World Specs You Can Trust

| Parameter | Specification |

|---|---|

| Brand/Model | GE Multilin MIFIIPI55E00HI00 |

| HS Code | 8537.10.0000 (Electrical protection apparatus) |

| Power Requirements | 88-264 VAC/VDC ±10%, 50/60Hz (typical industrial range) |

| Operating Temp | -40°C to +70°C (survives Canadian winters and Texas summers) |

| Signal Inputs | 4x CT inputs (1A/5A), HI00 = High-Impedance inputs for sensitive fault detection |

| Comms Interfaces | Dual Ethernet (IEC 61850), RS-485, USB for local config |

Where It Earns Its Keep

You’ll typically find this module guarding critical feeders in municipal substations – especially where aging infrastructure meets new solar farms causing harmonic distortion. A wastewater treatment plant in Ohio recently avoided $200k in downtime after it caught a high-impedance fault from corroded switchgear before the bus duct melted. It’s also become the go-to for wind farm collection systems where capacitor bank switching trips legacy relays weekly. Just don’t expect miracles on transmission-level voltages; this is strictly for distribution networks under 35kV.

Your Procurement Team Will Thank You

Beyond the obvious reliability boost, there’s real procurement value here. The modular design means you’re not stuck with over-specified units – configure exactly what your feeder needs today, add I/O later. GE’s firmware updates (released quarterly) actually fix field-reported issues, not just theoretical vulnerabilities. And let’s talk delivery: with 50% upfront payment, we ship in-stock units in 1 week flat. Worst case? 4 weeks for custom-configured models. Full payment only when it’s ready to ship – no surprises. Oh, and that 365-day warranty covers firmware glitches too, which matters when your SCADA system depends on those IEC 61850 reports.

Keeping It Running Smoothly

Installation’s straightforward if you follow GE’s guidelines: 19″ rack mount only (no DIN rail), minimum 100mm clearance above/below for convection cooling. I’ve seen too many failures from cramming it into cramped panels – those heat warnings pop up for a reason. Ventilation’s non-negotiable; ambient temps above 55°C will throttle performance. For maintenance? Skip the fancy calibration – just verify settings annually using the built-in self-test. Wipe vents quarterly (dust kills electronics faster than faults), and always apply firmware updates during planned outages. One caveat: never skip the IEC 61850 dataset validation after updates. I learned that the hard way during a midnight commissioning call last winter.

Built to Survive Real Substations

This isn’t lab-certified paperware. It’s UL 508A listed for industrial control panels, carries CE marking for EMC immunity (tested against 10V/m RF fields), and meets IEC 60255-27 for vibration resistance – crucial when mounted near breaker mechanisms. The conformal coating on PCBs handles coastal humidity that fries cheaper units. GE’s 5-year warranty on critical components (not just the standard 1-year) tells you everything about their confidence. One utility engineer told me: “It’s the only relay that didn’t glitch during our 2023 geomagnetic storm event.” That kind of real-world validation beats any spec sheet.

Reviews

There are no reviews yet.