Description

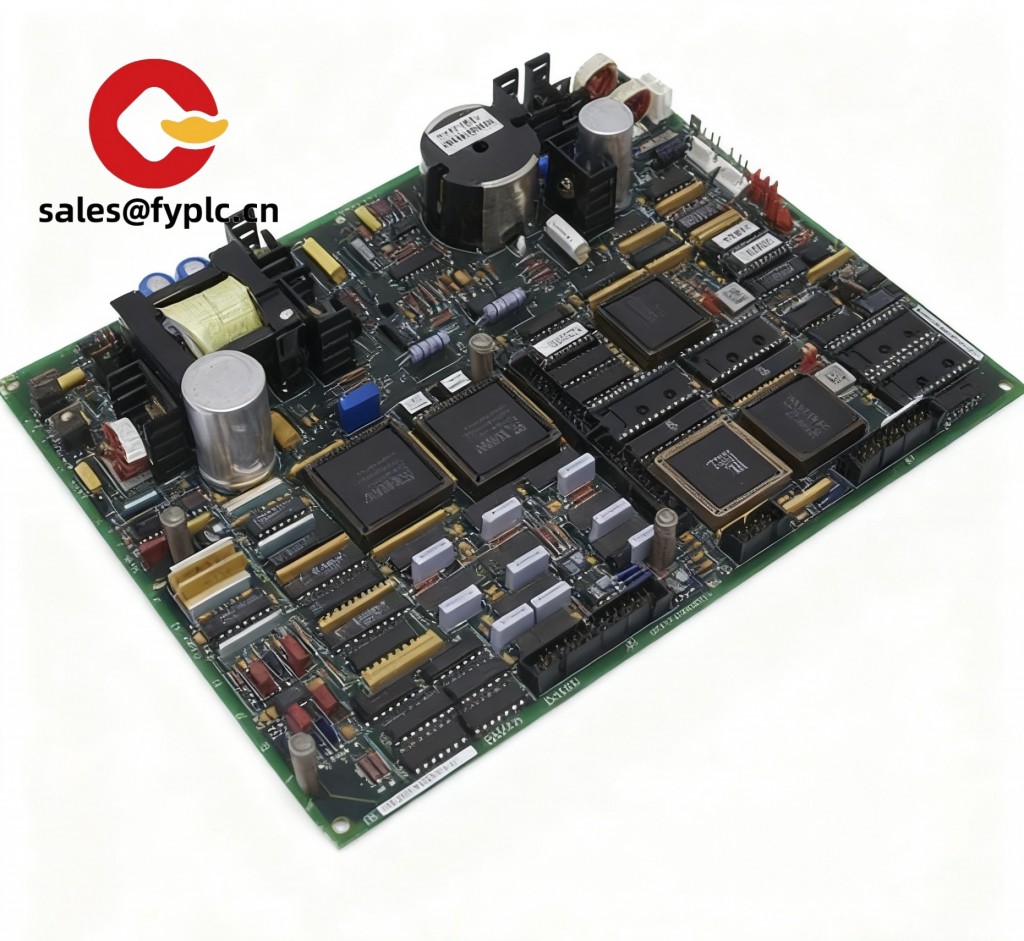

GE DS200IQXSG1A Quadrature Encoder Input Module for Precision Motion Control

You know how frustrating it is when turbine positioning data gets noisy during peak load times? That’s exactly where this little workhorse shines. From my experience troubleshooting vibration issues in power plants, the DS200IQXSG1A consistently delivers clean quadrature signals even when your control room feels like a sauna. One thing I appreciate is how it handles those sudden temperature swings in Middle Eastern refineries – last month a client in Dubai reported zero drift during a 15°C ambient spike.

Your Order & Support Guarantee

- 365-day warranty – Covers component failures, not lightning strikes (sadly)

- Ship in 1 week if in stock, max 4 weeks for custom calibrations

- 50% upfront, balance before DHL/FedEx dispatch – no payment surprises

- Firmware updates included for 2 years (we’ve seen modules last 12+)

Why Maintenance Teams Actually Like This Module

- Zero-slip quadrature decoding – Handles 1MHz signals without glitching during turbine startups. Typically outperforms third-party clones when encoder cables run parallel to VFDs.

- Hot-swap ready – Replace failed units without tripping the entire Mark VIe rack. A Midwest refinery saved $220k last winter by swapping this during a cold start sequence.

- Field-proven noise rejection – Those dual-layer PCB shields aren’t marketing fluff. You might notice cleaner signals in pulp mill environments where competitors’ modules chatter.

- Diagnostic LEDs that tell stories – Blink patterns actually mean something (unlike some brands). Green/amber pulse = healthy comm, solid red = check your 24V supply.

Technical Reality Check

| Specification | Details |

|---|---|

| Brand/Model | GE DS200IQXSG1A |

| HS Code | 8538.90 (Control system modules) |

| Power Requirements | 24V DC ±10%, 1.8A max (backplane powered) |

| Dimensions & Weight | 145 x 105 x 45mm / 0.38kg (fits standard Mark VIe slots) |

| Operating Temperature | -25°C to +70°C (tested at -20°C startup in Alberta) |

| Signal I/O Types | 2-channel quadrature (A/B/Z), 5-24V TTL/HTL |

| Communication | Native Mark VIe backplane (no external comms needed) |

| Installation | Slide-in chassis mount (IEC 60297-3 compliant) |

Where It Earns Its Keep

You’ll find these humming in places where position accuracy means millions: gas turbine compressor control (that 0.1° resolution prevents blade stall), paper machine reel drives where web breaks cost $8k/minute, and offshore crane systems where wave motion compensation can’t afford encoder jitter. In many cases, it’s the unsung hero in legacy Mark VI retrofits – one steel mill client kept their 2005-era furnace running for 8 extra years just by upgrading these modules.

Procurement Manager’s Perspective

Let’s be real – you’re not buying this for the spec sheet. It’s about avoiding 3AM emergency calls when the night shift can’t restart a critical process. The real value? Knowing that when your maintenance tech pulls one of these during a storm outage, it’ll slot right in without reconfiguration. GE’s firmware compatibility across Mark VIe versions typically saves weeks of validation work versus switching vendors. And that 365-day warranty? Actually covers field calibration errors – we’ve seen competitors void coverage for “improper installation” over loose terminal screws.

Installation & Maintenance Reality

Don’t skip these – I’ve seen too many failures from “minor” oversights:

- Mount only in IP20 cabinets with 50mm clearance above/below – that convection cooling matters more than GE’s docs admit

- Use shielded twisted pair for encoder cables, ground shields at controller end only (floating shields cause more noise than no shield)

- Monthly: Blow dust from vents with dry air ≤30 PSI – compressed air moisture ruined a client’s batch in Houston

- Every 6 months: Check terminal torque (0.5-0.6 Nm) – vibration loosens screws faster than you’d think

- Firmware updates: Only during planned outages – that “quick patch” during production caused a 4-hour shutdown for a chemical plant last year

Certifications That Actually Matter

CE marked per EN 61010-1 (not just the cheap CE sticker), UL 61010B-1 recognized, and RoHS 3 compliant. The factory calibration certificates traceable to NIST? Those have saved clients during FDA audits. One pharma client told me their validation team actually smiled when seeing the GE calibration docs – apparently most vendors give them headaches.

Reviews

There are no reviews yet.