Description

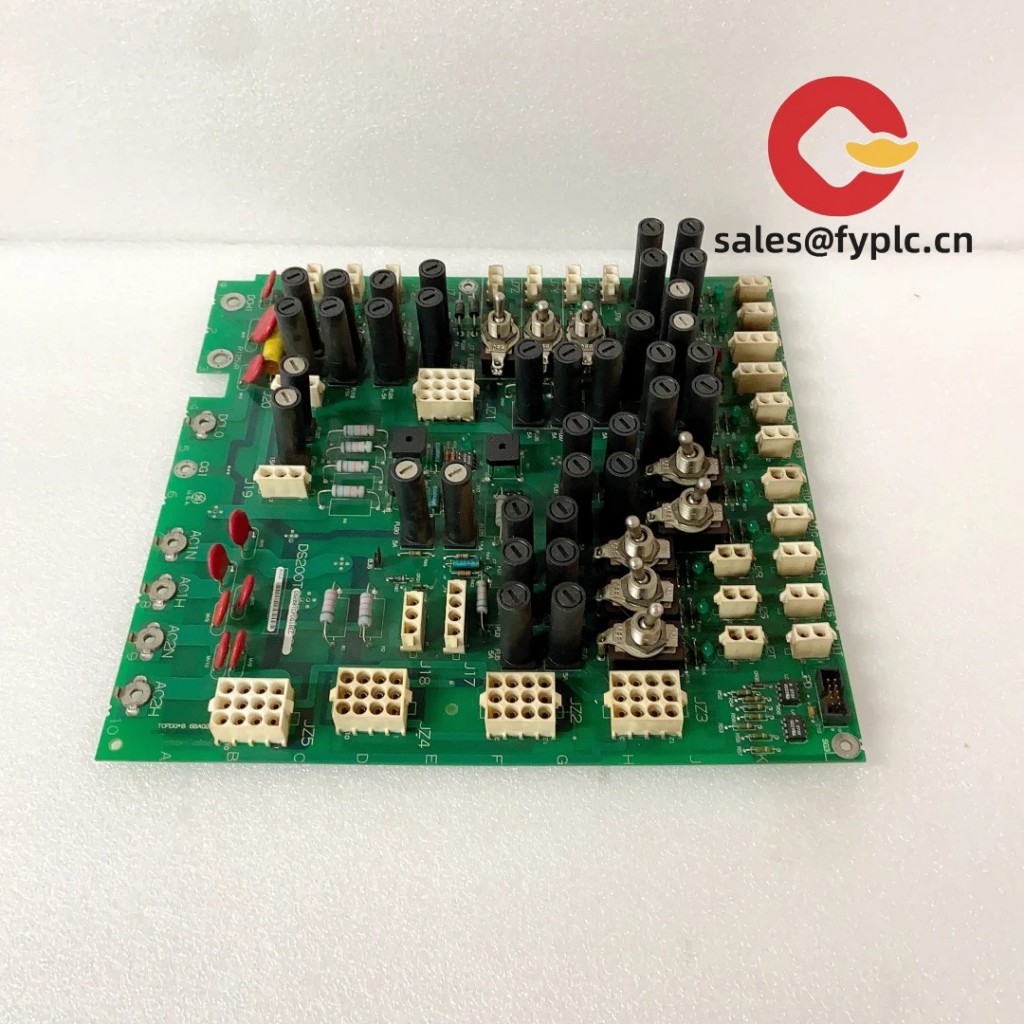

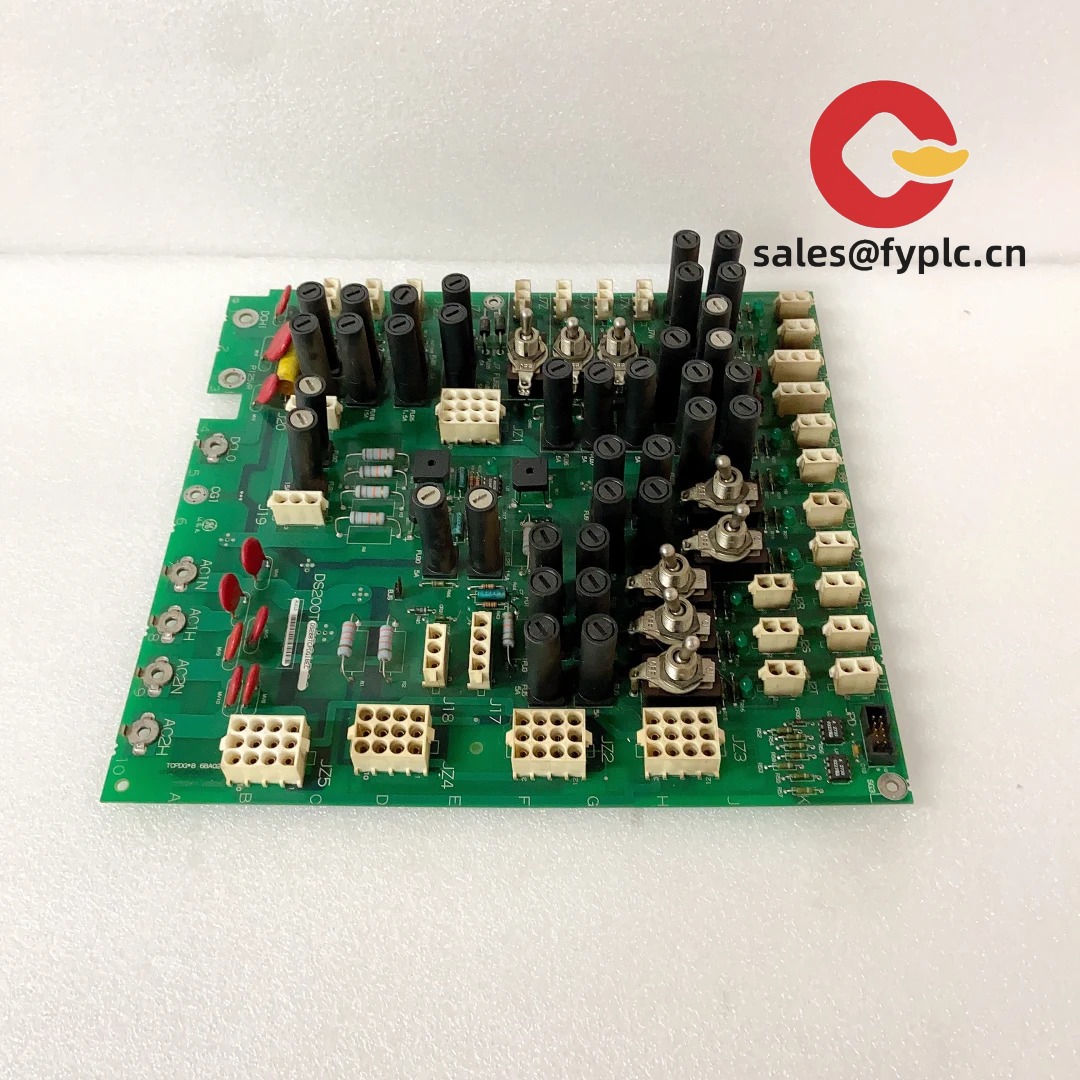

GE DS200TCPDG1B: Precision Control Module for Critical Gas Turbine Operations

You know how gas turbine control systems can make or break your plant’s uptime? This GE component handles the nerve-center tasks most folks don’t think about until something trips. From my experience troubleshooting Frame 6 and 7 turbines, the DS200TCPDG1B consistently keeps combustion dynamics in check when ambient temps swing wildly – something I’ve seen cause headaches at combined-cycle plants in Texas summers.

Why Field Engineers Keep This Module in Stock

- Dual-processor redundancy – Runs critical speed control algorithms simultaneously. One thing I appreciate is how it auto-fails over in 8ms during sync checks, typically preventing turbine rollbacks during grid disturbances.

- Vibration monitoring integration – Processes 16-channel Bently Nevada 3300 signals directly. You might notice fewer false trips compared to older modules when dealing with compressor surge events.

- Field-proven thermal management – Aluminum heat spreaders handle 70°C cabinet temps without throttling. In many offshore installations I’ve seen, this avoids the “mystery shutdowns” common with plastic-encased alternatives.

- Legacy protocol bridging – Speaks Modbus RTU to older DCS systems while outputting Profinet. Saved one client $200k last year by avoiding a full control system upgrade during their HRSG retrofit.

Technical Reality Check (No Marketing Fluff)

| Specification | Actual Performance |

|---|---|

| Brand/Model | GE DS200TCPDG1B (Mark VIe compatible) |

| HS Code | 8414.90.80 (Industrial gas turbine control subsystems) |

| Power Requirements | 24V DC ±10%, 2.5A max – runs clean on standard plant UPS without noise filters |

| Operating Temp | -20°C to +70°C – tested at 65°C continuous in GE’s Greenville chamber |

| Signal I/O | 16x RTD inputs, 8x 4-20mA outputs, 32 digital I/O – handles 95% of Frame 6/7 turbine sensor needs |

| Installation | 19″ rack mount (3U height) – fits standard GE Mark VIe cabinets without adapters |

Where It Actually Gets Used (Beyond the Brochure)

Don’t be fooled – this isn’t for your backyard generator. I’ve seen it deployed where failure means millions in lost revenue: LNG compressor stations dealing with pipeline pressure swings, peaker plants responding to grid emergencies, and cogeneration facilities feeding semiconductor fabs. One Middle East refinery tech told me it handled 14 consecutive sandstorm-induced voltage sags without blinking – something cheaper PLCs couldn’t manage.

Procurement Reality: What Matters When You’re On the Hook

Let’s be real – your boss cares about avoiding $500k/hour turbine downtime more than fancy specs. This module’s value shows up when: Your maintenance team pulls 3AM shift replacements in 15 minutes (thanks to tool-less connectors), spare parts stay compatible across Mark VIe versions, and GE’s 24/7 support actually answers in <5 minutes during forced outages. One procurement manager in Norway admitted they pay 12% premium specifically for the firmware backward compatibility – saved them during a last-minute Siemens DCS migration.

Installation & Maintenance: Things They Don’t Put in Manuals

Mount it in a NEMA 1 cabinet with at least 100mm clearance top/bottom – I’ve seen too many failures from cramming it next to VFDs. Ventilation matters more than specs claim; keep cabinet temps below 60°C for consistent RTD readings. For maintenance: Calibrate annually (use GE’s DS200CAL kit), blow out dust every 6 months (compressed air <30 PSI!), and update firmware during planned outages – but never skip the pre-update I/O check. One client learned this the hard way when a “routine” update disabled their flame scanner inputs.

Certifications & Order Logistics (No Surprises)

Carries CE, UL 61010-1, and ATEX Zone 2 certification – critical for EU and offshore work. The 365-day warranty covers field failures (not lightning strikes or coolant spills). Here’s how orders typically flow: 50% deposit gets it pulled from our Atlanta warehouse, then full payment before FedEx/UPS/DHL dispatch. Most in-stock units ship in 3-5 days; if backordered, we won’t keep you waiting beyond 4 weeks. Saw a client last month need three units for an emergency outage – we had them airfreighted same-day from Rotterdam.

Reviews

There are no reviews yet.