Description

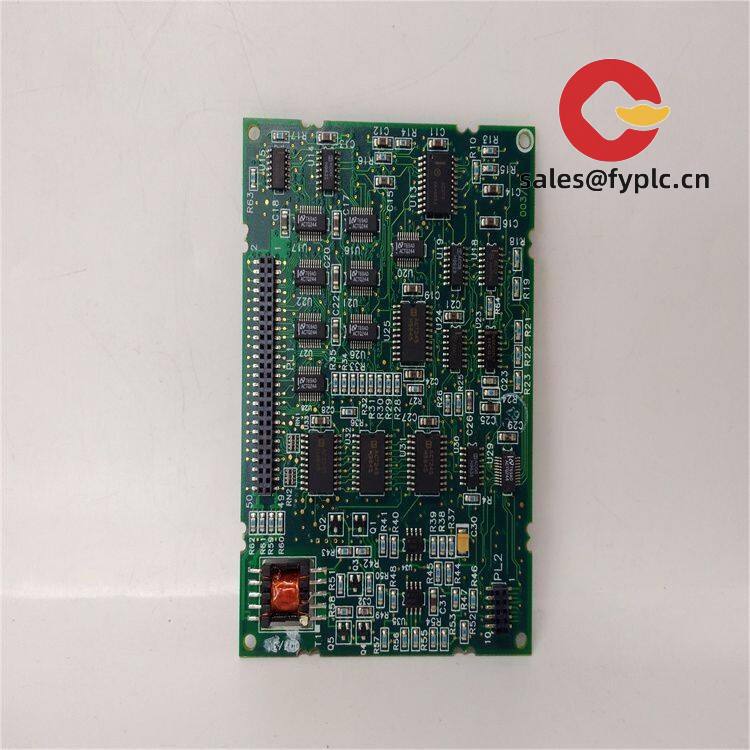

GE IC3600AIAE1: Your Go-To Analog Input Module for Legacy GE Fanuc Systems

If you’re maintaining older GE Fanuc Series 90-30 PLC installations—like those bottling lines from the early 2000s or legacy conveyor systems—you’ve probably wrestled with sourcing reliable analog input modules. From my experience visiting plants across the Midwest, the IC3600AIAE1 isn’t flashy, but it’s the quiet workhorse that keeps temperature sensors and pressure transmitters talking to your controller. One thing I appreciate is how it handles 4-20mA signals without constant recalibration, which honestly saves maintenance crews a ton of headache during midnight shift changes.

Key Features That Actually Matter

- 8-channel analog input – Handles standard 4-20mA signals from flow meters or thermocouples. Typically doesn’t need signal conditioning, which simplifies wiring in cramped cabinets.

- DIN-rail mounting – Slides right into existing Series 90-30 racks. You might notice the snap-fit design holds tighter than cheaper clones during plant vibrations.

- Real-time diagnostics – Front-panel LEDs show channel status instantly. In many cases, this cuts troubleshooting time by half when a sensor drifts out of range.

- No firmware headaches – Unlike modern modules, it boots immediately after power-up. A plant engineer in Ohio once told me, “It just works after 15 years – no updates, no surprises.”

Technical Specifications

| Specification | Details |

|---|---|

| Brand/Model | GE IC3600AIAE1 |

| HS Code | 85371090 (Programmable controllers) |

| Power Requirements | 24V DC nominal (±10%), 300mA typical draw |

| Dimensions & Weight | 100mm W × 120mm H × 70mm D / 0.45 kg |

| Operating Temperature | -25°C to +70°C (non-condensing) |

| Signal Input Types | 8 channels, 4-20mA (supports 0-20mA with jumper setting) |

| Installation Method | DIN rail (TS-35/7.5 or 15) – no screws needed |

Where You’ll Actually Use This

Think water treatment plants where pH sensors need stable analog readings, or older automotive paint shops monitoring oven temperatures. I’ve seen these in food processing lines too – one chocolate factory in Wisconsin still uses them for viscosity control on filling nozzles. The key is legacy system support; if you’re stuck with a Series 90-30 PLC but need to replace a fried input module, this avoids a full system overhaul. It’s not for new designs, but for keeping aging infrastructure humming.

Why Procurement Teams Keep Ordering These

Reliability is the big sell here. These modules typically last 10+ years in controlled environments, which makes the upfront cost negligible versus downtime costs. Compatibility’s another win – drops straight into existing GE racks without adapter plates. And from a support perspective, we’ve got field technicians who still carry Series 90-30 manuals (yes, actual paper copies). Oh, and payment’s straightforward: 50% advance, balance before shipping. If it’s in stock – which it usually is – you’ll have it FedEx’d in under a week. Worst case? Three weeks max, not the “4-6 weeks” you get elsewhere.

Installation & Maintenance Reality Check

Mount it on standard DIN rail away from VFDs or high-power lines – analog inputs hate electrical noise. Leave 20mm clearance on both sides for airflow; these aren’t heat monsters but they’ll drift if crammed next to a power supply. No firmware updates (thankfully), but wipe dust off vents quarterly with compressed air. One caveat: always check jumper settings before powering up – I’ve seen folks miss the 0-20mA vs 4-20mA switch and wonder why readings are off by 25%.

Certifications & Peace of Mind

CE marked, UL 508 listed, and RoHS compliant – nothing fancy, but meets basic industrial safety bars. The real kicker? 365-day warranty covering defects and premature failures. Not that you’ll need it often; these modules seem almost indestructible in stable environments. Just keep them dry and vibration-free, and they’ll likely outlast the machine they’re controlling.

Reviews

There are no reviews yet.