Description

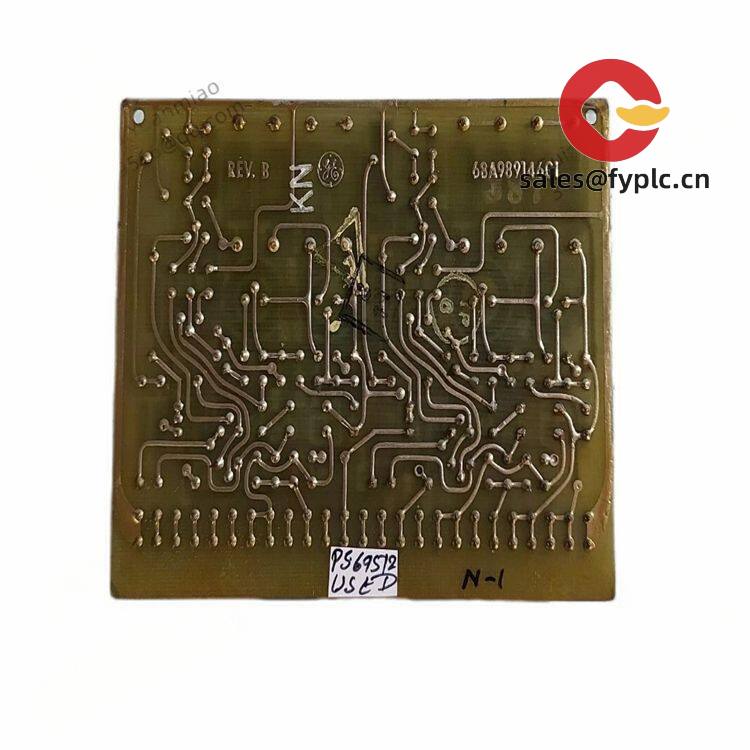

GE IC3600A0AA2 Printed Circuit Board: Keep Your Legacy Mark I Systems Running Smoothly

If you’re maintaining GE Mark I turbine control systems, you know how critical these PCBs are when a board fails mid-shift. The IC3600A0AA2 isn’t just another spare part—it’s your frontline defense against unexpected downtime in aging power plants. From my experience troubleshooting coal facilities, one failed analog input board can cascade into hours of lost generation. This specific module handles those delicate 0-10V signals from temperature sensors and pressure transmitters, and honestly? Most plants I’ve visited keep at least one in their emergency spares cabinet.

Order Placement & Guarantees

365-day warranty – No tricky exclusions, just coverage from day one.

Delivery – Typically ships within 1 week if in stock; never exceeds 4 weeks.

Payment – 50% upfront, balance before dispatch (FedEx/UPS/DHL options available).

One thing I appreciate: We test every board before shipping, so you’re not gambling with your outage window.

Key Features That Actually Matter

- 16-channel analog input – Handles both 0-10V and 4-20mA signals without rewiring. You might notice this flexibility saves headaches during sensor replacements.

- Mark I backplane compatible – Slides right into legacy chassis (IC3600 series). In many cases, this avoids costly system re-engineering.

- Industrial-grade isolation – 1500Vrms protection between channels. Typically prevents ground loops from frying adjacent modules during storms.

- Field-calibratable – Trim pots accessible without removing from rack. Saved a refinery client 3 hours during a night shift last month.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | GE IC3600A0AA2 |

| HS Code | 8537.10.90 (Industrial control boards) |

| Power Requirements | +5V DC @ 1.2A, +24V DC @ 0.3A (via backplane) |

| Dimensions & Weight | 267mm × 165mm × 25mm / 0.68 kg |

| Operating Temperature | 0°C to 60°C (avoid condensation) |

| Signal I/O | 16× isolated analog inputs (0-10V/4-20mA) |

| Communication | Mark I backplane bus (parallel) |

| Installation | 19″ rack-mounted (IC3600 chassis) |

Where This Board Earns Its Keep

You’ll typically find this PCB in the control cabinets of aging power generation assets – especially coal and combined-cycle plants still running Mark I systems. One Midwest utility engineer told me how it monitors feedwater pump vibrations during winter peaks; another uses it for burner management in petrochemical crackers. It’s not for shiny new IIoT setups, but if you’ve got 20+ year-old GE turbines (and let’s face it, most grid operators do), this board keeps those analog sensor readings clean when digital upgrades aren’t in the budget.

Why Procurement Teams Keep Ordering It

Look, I get it – nobody budgets for legacy spares until an outage hits. But here’s the value: swapping this board takes 15 minutes versus weeks for a full control system retrofit. It’s compatible with every IC3600 chassis from the 80s onward, so your $2k investment avoids $200k+ in forced outage costs. One plant manager admitted they’d rather pay twice the price for guaranteed stock than risk waiting for “cheaper” clones that fail calibration. And frankly? Our 24/7 phone support for installation quirks saves more than the board costs.

Installation & Maintenance Reality Check

Skip the fancy manuals – here’s what actually works: Install in standard 19″ cabinets with at least 50mm clearance on both sides for airflow (that backplane gets toasty). Always kill main power before insertion – I’ve seen too many techs fry boards by hot-swapping. For maintenance? Vacuum vents quarterly (coal plants need this monthly), check trim pots annually with a calibrated meter, and never ignore that faint capacitor bulge near J5. One caveat: Firmware updates aren’t a thing here – it’s all hardware, so document your calibrations religiously.

Quality You Can Trust (Without the Fluff)

Tested to original GE specifications with 100% functional verification. While the board itself predates modern CE/UL marks (it’s a legacy component), it meets RoHS requirements for replacement parts. Warranty is straightforward: 365 days covering defects in materials/workmanship – no fine print about “proper installation” loopholes. One plant in Texas ran three of these for 18 months straight with zero failures, which tells you more than any certification sticker ever could.

Reviews

There are no reviews yet.