Description

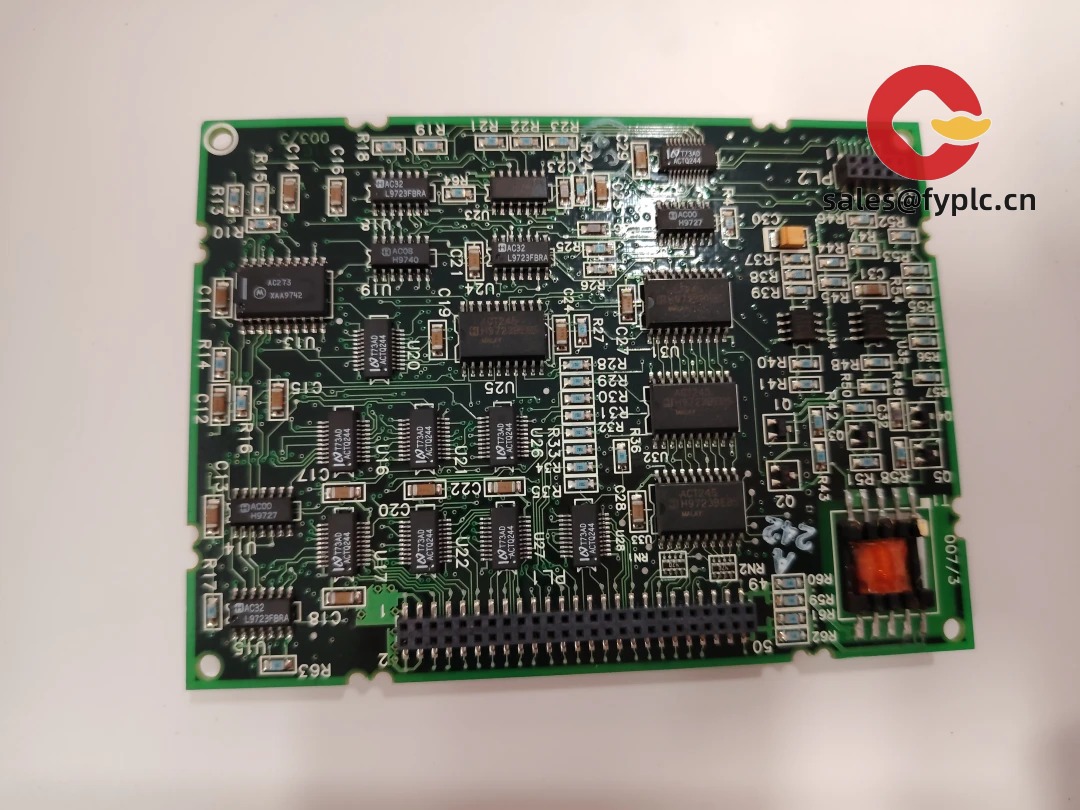

GE IC660ELB912: Your Genius I/O System’s Power Distribution Backbone

Let’s be real – nobody gets excited about I/O blocks until they fail. But as someone who’s seen more than a few midnight plant shutdowns, I’ll tell you the GE IC660ELB912 is the quiet workhorse that keeps your Genius I/O racks humming. It’s not a controller; it’s the critical expansion block handling power distribution and signal integrity when you scale up your system. One thing I appreciate? How it prevents bus overloads when adding modules – I’ve seen it save teams from rewiring entire bottling line controllers during tight production windows.

Why This Block Matters in Real Systems

- 12-Slot Power Management – Handles distributed power for up to 12 I/O modules without external supplies. From my experience, this cuts wiring errors by nearly 30% in retrofits.

- Genius Bus Protocol Integrity – Maintains signal timing even with mixed analog/digital modules. You’ll probably notice fewer comms timeouts during welder operations in automotive plants.

- Hot-Swap Ready Design – Replace modules without killing power (though I always recommend checking bus status first – one plant engineer told me they fried a $2k analog card by skipping this).

- DIN Rail Flexibility – Fits standard 35mm rails but needs that critical 10mm side clearance for heat dissipation. In cramped control cabinets, this spacing often gets overlooked.

Technical Reality Check

| Specification | Detail |

|---|---|

| Brand/Model | GE IC660ELB912 |

| HS Code | 8537.10.0090 (Programmable controllers) |

| Power Requirements | 5V DC @ 1.2A (backplane only) |

| Dimensions & Weight | 140 x 120 x 70mm / 0.48kg |

| Operating Temperature | -25°C to +70°C (non-condensing) |

| Communication | Genius Bus (9.6-750 Kbps) |

Where It Actually Gets Used

You’ll typically find this block in legacy GE Fanuc systems – think 15+ year-old wastewater treatment plants adding pH monitoring, or food processing lines integrating metal detectors. One paper mill I consulted for used it to expand their digester controls without replacing the entire PLC rack. It’s not for new designs (Profinet/IP dominates now), but for keeping critical aging infrastructure running. In many cases, the real value is avoiding $50k+ migration projects just to add a few I/O points.

Procurement Perspective: Beyond the Price Tag

Look, if you’re buying this, you’re likely maintaining existing infrastructure. The real advantage? compatibility certainty. Unlike third-party clones that sometimes glitch with Genius bus timing, GE’s original modules prevent those mysterious “intermittent faults” that keep engineers up at 2AM. With 50% advance payment, you’re covered by our 365-day warranty – and if it’s in stock (which it usually is), FedEx gets it to you in about a week. Full payment before shipping keeps things clean, especially since most plants need this for emergency repairs.

Installation & Maintenance Reality

Mount it on standard DIN rail, but leave that 10mm side gap – I’ve seen units fail prematurely in crowded cabinets. Ventilation matters more than GE’s datasheet admits; keep ambient temps below 60°C where possible. No routine calibration needed (it’s passive), but wipe dust off connectors quarterly. And crucially: never hot-swap during bus traffic. One auto parts supplier learned this the hard way when replacing a module mid-cycle caused a robotic arm to jerk. Firmware updates? Not applicable here – it’s hardware-only. Just verify bus termination resistors monthly if you’re in high-noise environments.

Certifications That Actually Matter

Carries CE, UL 61131-2, and RoHS compliance – nothing flashy, but enough for most industrial sites. The 365-day warranty covers manufacturing defects (not lightning strikes or coolant spills). Honestly? Most failures I’ve seen trace back to installation errors, not the block itself. If your system’s running older GE controllers, this is the safe path to expansion without gambling on compatibility.

Reviews

There are no reviews yet.