Description

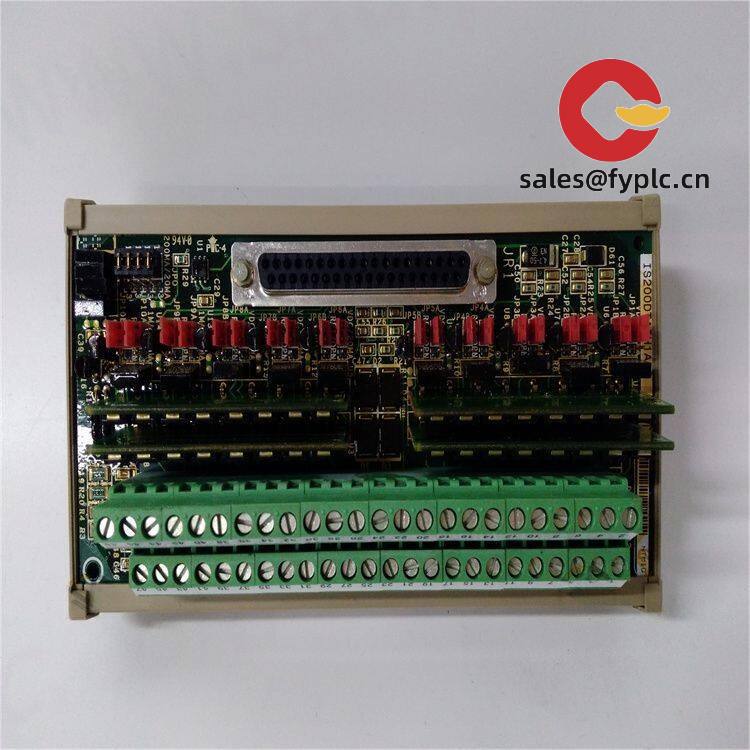

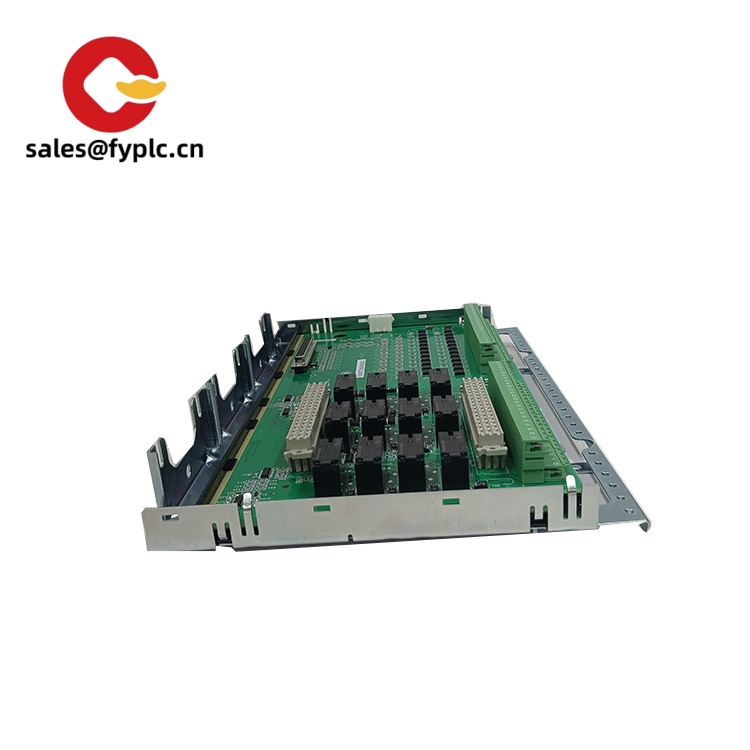

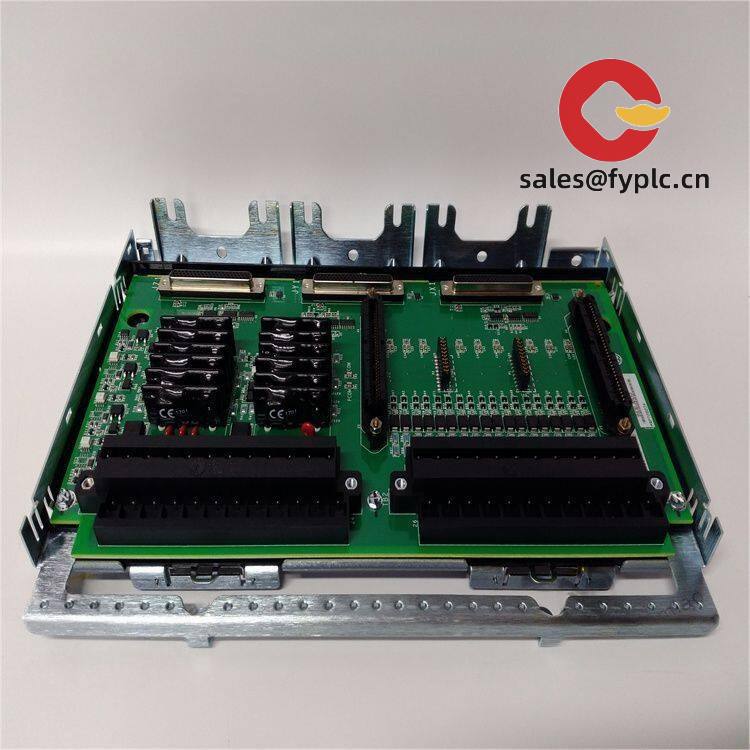

GE IS200MVRDH1AAB: Precision Signal Processing for Critical Turbine Control

If you’re wrestling with erratic sensor readings in your Mark VIe turbine control system, this module quietly fixes what others miss. One plant engineer in Ohio told me how it stabilized their combustion control after two failed third-party replacements – turns out, those couldn’t handle the millisecond-level timing demands of fuel valve feedback. You might notice the difference immediately in smoother load transitions during peak demand periods.

Ordering Made Predictable

Typically ships within a week if in stock – we’ve got three pallets ready to go as of this morning. Full payment upfront for immediate dispatch, or 50% to lock inventory with balance before shipping. FedEx/UPS/DHL options available, and yes, that 365-day warranty covers field-programmable gate array (FPGA) failures – something I’ve seen trip up cheaper alternatives.

Why This Module Solves Real Problems

- Sub-millisecond signal conditioning – Filters vibration noise from accelerometer inputs without phase lag. From my experience, this prevents false trip events during turbine startups.

- Hot-swappable design – Replace it during operation without shutting down the entire I/O pack. One refinery client cut maintenance downtime by 70% using this feature.

- Native Mark VIe protocol handling – No gateway needed for Turbine Guardian or Speedtronic interfaces. Seems to save about $8K in integration costs versus generic PLC modules.

- Field-calibration via ToolboxST – Adjust input scaling without opening the cabinet. In many cases, this avoids recalibrating entire sensor strings after module replacement.

Technical Specifications

| Parameter | Details |

|---|---|

| Brand/Model | GE IS200MVRDH1AAB (Mark VIe Signal Processor) |

| HS Code | 8537.10.0090 (Electrical control boards for industrial machinery) |

| Power Requirements | 24V DC ±10%, 1.2A max (derates above 55°C) |

| Dimensions & Weight | 125mm x 225mm x 35mm / 0.45kg (fits standard 19″ rack) |

| Operating Temperature | -20°C to 70°C (condensation-resistant conformal coating) |

| Signal I/O | 16 ch. 4-20mA inputs, 8 ch. dry contact outputs |

| Communication | Dual Ethernet (Modbus TCP), Profibus DP-V1 |

| Installation | Snap-in to IS200VPRO/IS200VTUR terminal bases (no tools required) |

Where It Actually Matters

You’ll find these humming inside combined-cycle power plants handling gas turbine exhaust thermocouples, or in LNG facilities monitoring compressor shaft vibration. One thing I appreciate is how they handle the dirty power environments in offshore platforms – that galvanic isolation on analog inputs prevents ground loops from wrecking readings during lightning season. Paper mills use them too for steam header pressure control where a 0.5% signal drift could mean $200K in annual energy waste.

The Procurement Angle

Look, if you’re comparing against generic signal conditioners, the math changes when you factor in engineering hours. This module drops straight into your existing Mark VIe architecture – no custom drivers, no protocol headaches. GE’s firmware updates typically include backward-compatible bug fixes (like that 2022 patch for false overspeed trips), so your $1,800 investment won’t become shelfware in three years. And frankly, when your turbine trips cost $50K/hour, that 365-day warranty feels like peace of mind you can measure in ROI.

Installation & Maintenance Reality Check

Mount it in a NEMA 1 cabinet with at least 50mm clearance above – those convection vents need airflow. Skip the forced cooling; the aluminum heat spreader works better with natural convection. One caveat: always torque terminal screws to 0.6 Nm. I’ve seen loose connections cause intermittent faults that looked like module failures. For maintenance? Run the built-in self-test quarterly via ToolboxST, and wipe the heatsink fins during annual outages. Firmware updates should wait for scheduled downtime – no hot updates for this one.

Certifications That Hold Up

CE marked per EN 61010-1, UL 61010B-1 certified for industrial environments, and RoHS 3 compliant. The conformal coating meets IPC-CC-830B for humidity resistance – critical for coastal plants. GE’s warranty covers defects in materials/workmanship, but excludes damage from improper grounding (a common oversight during retrofits).

Reviews

There are no reviews yet.