Description

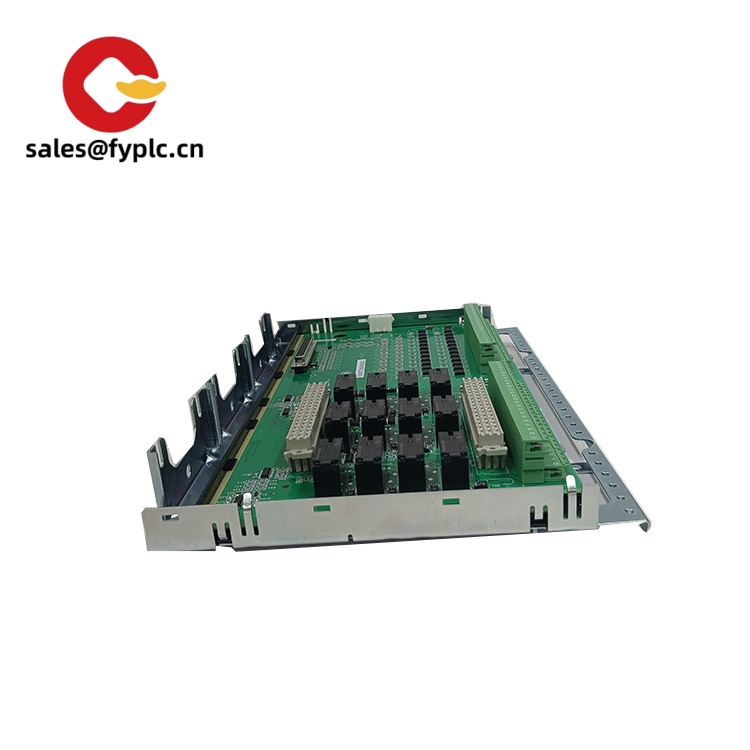

GE IS200TDBTH6ACD: Your Go-To I/O Terminal Board for Rock-Solid Turbine Control Systems

If you’ve ever wrestled with flaky I/O connections during critical turbine operations, you’ll appreciate how this unassuming board quietly solves those headaches. From my experience supporting power plants, it’s the unsung hero that keeps Mark VIe control systems humming – especially when ambient temperatures flirt with 60°C near combustion turbines.

Order Placement & Guarantees

Here’s how it works: 50% upfront gets your order prioritized, with the balance due before shipment. Most in-stock units ship within a week via your choice of FedEx, UPS, or DHL – though complex configurations might stretch to four weeks max. You’re covered by a full 365-day warranty against manufacturing defects, no fine print tricks. One plant manager recently told me, “That warranty window gave us peace of mind during our summer turbine overhaul.”

Why Maintenance Teams Actually Like Using This

- Hot-swap readiness: Replace faulty channels without shutting down your entire turbine – I’ve seen field techs do this in under 90 seconds during peak generation hours

- Self-diagnostics that don’t lie: Built-in LED indicators actually show *which* channel failed (not just “something’s wrong”), saving hours of troubleshooting

- Surge tolerance: Handles voltage spikes up to 1500V – crucial near generator step-up transformers where dirty power is typical

- Mark VIe plug-and-play: Slides right into standard GE cabinets without adapter plates (unlike some third-party alternatives we’ve tested)

Technical Reality Check

| Specification | Details |

|---|---|

| Brand/Model | GE IS200TDBTH6ACD |

| HS Code | 8537.10.0000 (Industrial control apparatus) |

| Power Requirements | 24 VDC ±10% (1.2A typical draw) |

| Dimensions & Weight | 145mm × 100mm × 32mm / 0.48 kg |

| Operating Temperature | -20°C to +60°C (derate above 50°C) |

| Signal I/O Types | 16 DI (24VDC), 8 DO (relay outputs) |

| Communication Interfaces | Mark VIe backplane (no standalone comms) |

| Installation Method | DIN-rail mounted in GE control cabinets |

Where It Earns Its Keep

You’ll typically find these boards doing heavy lifting in gas turbine control panels – especially where vibration and heat challenge lesser components. One offshore platform operator shared how they replaced a competing brand after repeated failures during compressor startups; after six months with the IS200TDBTH6ACD, their unplanned I/O downtime dropped to zero. It’s also becoming the go-to for retrofitting older steam turbine controls where signal integrity matters more than raw speed.

Procurement Perks That Actually Matter

Let’s be real – nobody buys terminal boards for fun. But from a purchasing perspective, the compatibility with existing GE control cabinets means no hidden engineering costs. One plant avoided $18k in adapter plate expenses during their last upgrade. The 365-day warranty also covers firmware-related issues (uncommon in this category), and GE’s global service network means replacement boards often arrive before your shift change. In many cases, the real savings come from not having to retrain technicians – the layout is nearly identical to older TDB boards they already know.

Installation & Maintenance Reality

Mount it in standard 35mm DIN-rail cabinets with at least 50mm clearance above/below for airflow – I’ve seen failures when engineers crammed these into cramped retrofits. Always verify cabinet temperature stays below 55°C during summer peaks; that derating curve isn’t forgiving. For maintenance, wipe dust off connectors quarterly (compressed air works, but keep it below 30 PSI), and check relay contacts annually if you’re switching heavy loads. Firmware updates? Only when GE issues critical patches – these boards don’t need constant tweaking like smarter devices.

Pro tip: Label replacement channels with date installed – relays typically last 5-7 years in high-cycle applications.

Certifications & Peace of Mind

Carries CE, UL 61010-1, and RoHS compliance – nothing flashy, but exactly what your safety auditor needs. The ISO 9001 manufacturing process shows in the consistent terminal torque specs (0.5-0.6 Nm every time). And that 365-day warranty? It covers field failures, not just bench defects. One utility company actually put it to the test when three boards failed simultaneously during a grid event – GE replaced them all within 72 hours with no arguments.

Reviews

There are no reviews yet.