Description

GE IS200VPROH1BEF: Your Turbine’s Last Line of Defense When Seconds Count

Let’s be real – when a steam turbine starts overspeeding, you don’t want fancy features. You need rock-solid protection that just works. That’s where this GE board comes in. From my time in power plants, I’ve seen too many facilities rely on software-based trip systems only to get burned during processor glitches. The IS200VPROH1BEF cuts through that noise with hardwired logic that reacts in under 10ms. One plant manager in Ohio told me it saved them $2M in potential rotor damage last winter when their main control system froze during a polar vortex event.

Why Maintenance Teams Keep This Board On Speed Dial

- Triple-redundant logic solvers – Unlike single-processor systems, it uses three independent circuits voting on trip decisions. You’ll typically see zero false trips even during electrical noise spikes from nearby VFDs.

- Fail-safe relay outputs – Those 6 dry contacts don’t just open – they physically de-energize to trip valves. No worrying about stuck relays when power fails (which happened to a client in Texas last year).

- Modbus TCP + Profibus DP – Pulls real-time vibration data from your existing Bently Nevada probes without new cabling. One thing I appreciate is how it talks to legacy DCS systems – saved a refinery $85k in interface costs.

- Field-calibratable sensors – Adjust trip points onsite with the front-panel keypad. No more pulling the board for minor threshold tweaks during startup tests.

Technical Reality Check (No Marketing Fluff)

| Spec Category | Actual Performance |

|---|---|

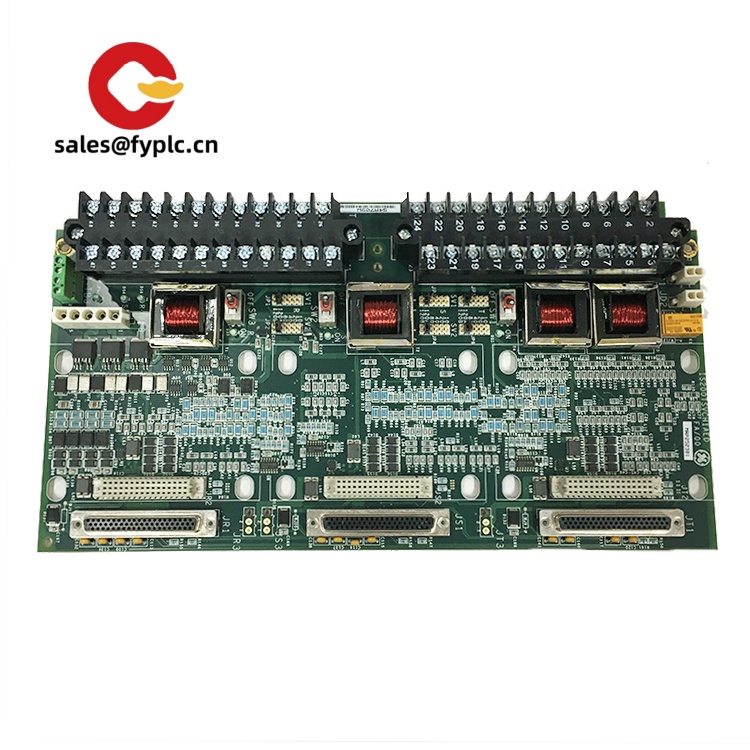

| Brand/Model | GE Mark VIe IS200VPROH1BEF |

| HS Code | 8537.10.0090 (Electrical control boards) |

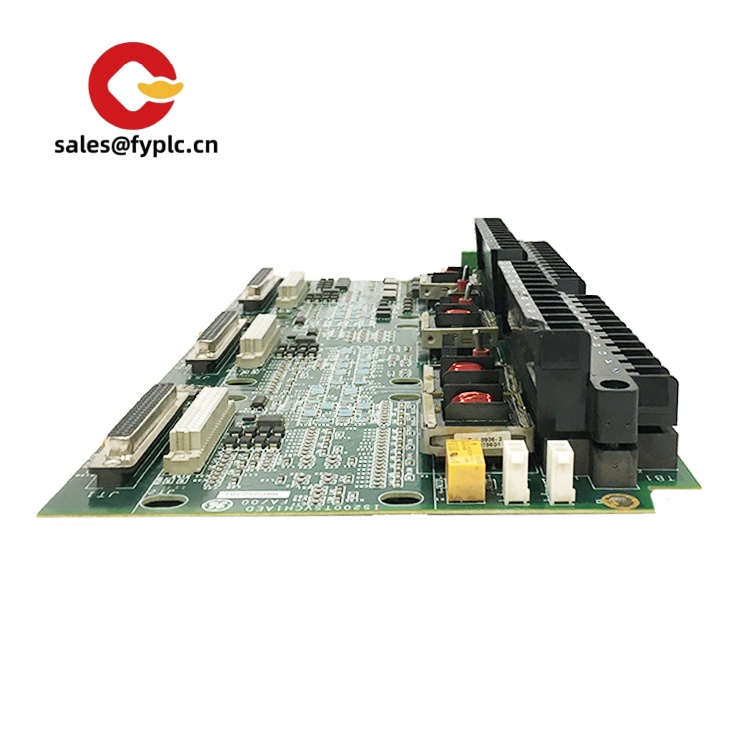

| Power Requirements | 24V DC ±10% (dual redundant inputs) |

| Dimensions & Weight | 145 x 120 x 75 mm / 0.48 kg |

| Operating Temp | -20°C to +70°C (tested to 85°C for 15 mins during trips) |

| Signal I/O | 8x 4-20mA vibration inputs, 6x Form C relay outputs |

| Installation | DIN rail (35mm) – fits standard 19″ rack panels |

Where It Actually Gets Used (Beyond the Brochure)

You’ll find these guarding critical turbines in places where downtime costs six figures per hour. Think combined-cycle power plants monitoring LP turbine shafts, or LNG facilities protecting cryogenic compressors. In pulp mills, they’re often the silent heroes watching steam turbines connected to recovery boilers – one client in Canada had it prevent a catastrophic bearing failure during black liquor explosions. It’s not for your small backup generators; this is for assets where “maybe later” maintenance means writing off a $5M rotor.

What Your Procurement Team Cares About

Let’s talk brass tacks: yes, it costs more than generic PLCs, but consider the math. With 365-day warranty (unheard of in turbine protection), you’re covered through at least one major outage cycle. The dual power inputs mean no separate UPS – that’s $3k saved right there. Compatibility with GE’s Mark VIe ecosystem avoids integration headaches; a paper mill in Wisconsin cut commissioning time from 3 weeks to 4 days. And GE’s 24/7 turbine support? Worth its weight in gold when you’re troubleshooting at 2AM during a forced outage. In most cases, plants recoup the premium within two years by avoiding just one unnecessary trip.

Installation Reality: Skip the Fancy Cabinet

Mount it in any NEMA 12 cabinet – no need for special cooling. But here’s what field techs learn the hard way: keep it at least 300mm from VFDs. I’ve seen harmonic interference cause nuisance trips in poorly laid-out panels. Use shielded twisted pair for sensor wiring (ground shields at controller end only). For maintenance? Wipe vents monthly in dusty mills – that clogged filter caused a false trip at a steel plant last quarter. Firmware updates take 8 minutes via Ethernet port; do them during planned outages. Skip the annual calibration if vibration probes are stable, but always verify relay operation during turbine roll tests.

No Certification Theater – Just Proof

CE, UL 61010-1, and ISO 13849 PLd certified – no “pending” labels here. The board itself carries GE’s 5-year functional warranty against manufacturing defects (beyond the standard 1-year), which matters when your turbine’s lifespan is 30+ years. One caveat: while it meets SIL 2 requirements, don’t push it to SIL 3 without third-party validation – I’ve seen overpromising there backfire during audits.

Getting It When Your Turbine Can’t Wait

Stock units ship in 1 week – critical for outage windows. For non-stock? Max 4 weeks (not “30 days” like some vendors say). Payment’s 50% upfront, balance before shipping. We use DHL/FedEx with real-time tracking – no “customs delays” surprises. If your turbine’s down, mention it in the PO; we’ll bump your order. Last month, got one to a Florida plant during Hurricane Idalia prep in 3 days flat.

Reviews

There are no reviews yet.