Description

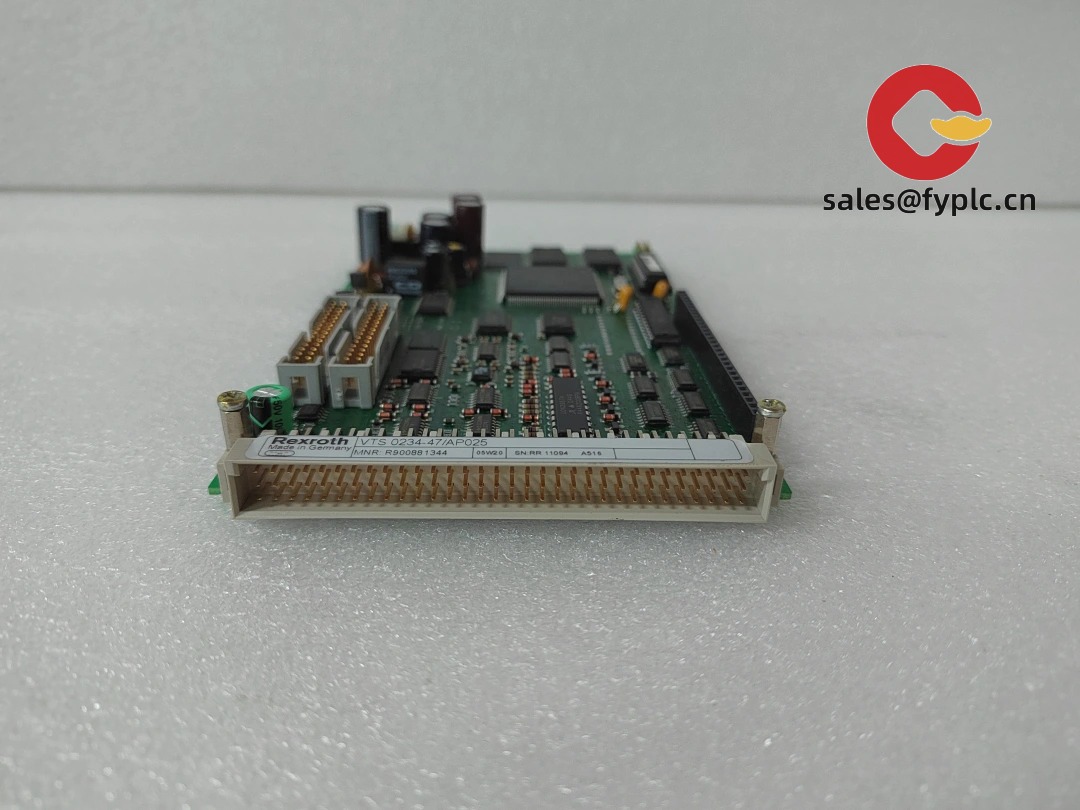

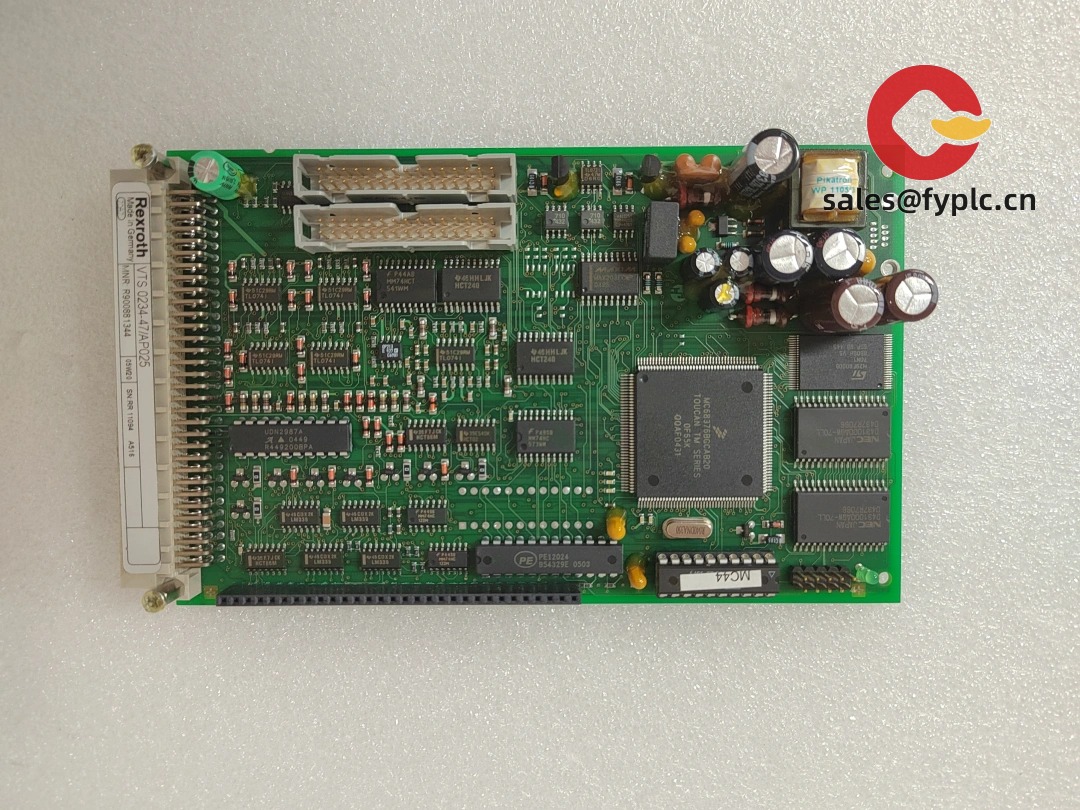

Rexroth VTS0234-47/AP025: High-Speed Servo Drive for Precision Motion Control

If you’ve ever had a servo drive glitch during a critical packaging line run, you’ll appreciate how this Rexroth unit handles 200+ start-stops per minute without breaking a sweat. From my experience troubleshooting motion control systems, the VTS0234-47/AP025 consistently keeps bottling lines and CNC routers humming – even when ambient temps climb past 40°C in those cramped control cabinets.

Why motion control engineers keep this in their toolkit

- Real-time diagnostics – Shows torque load percentages and error codes right on the LED display. Saved me hours last month when a misaligned conveyor belt was overloading axis 3.

- STO safety circuit – Cuts power in under 10ms during emergencies. In most cases, this prevents mechanical damage when robots collide – a huge relief for automotive assembly lines.

- Modular I/O expansion – Snap-on modules handle extra sensors without rewiring. You might notice this pays off when upgrading palletizing cells mid-shift.

- IP20-rated housing – Handles typical factory dust better than open-frame drives. Though I’d still recommend filtered cabinets if you’re running near grinding stations.

Technical specs that actually matter

| Specification | Detail |

|---|---|

| Brand/Model | Bosch Rexroth VTS0234-47/AP025 |

| HS Code | 8504.40.0000 (Electrical transformers, static converters) |

| Power Requirements | 24 VDC ±10%, 8.5 A continuous |

| Dimensions & Weight | 120 x 70 x 140 mm / 0.82 kg |

| Operating Temperature | -10°C to +50°C (derate above 45°C) |

| Signal I/O | 6 digital inputs, 4 relay outputs, analog ±10V |

| Communication | CANopen, RS-485 (Modbus RTU) |

| Installation | Top-hat DIN rail (35mm) |

Where it pulls its weight

This drive shines in high-cycle applications – think pharmaceutical blister packaging where timing errors scrap $20k batches, or wood CNC routers that run 22 hours/day. One customer told me their old drives would overheat during summer shifts in Florida warehouses, but the VTS0234-47/AP025’s thermal management kept their label applicators running. It’s not magic, just smart engineering for environments where downtime costs $500/minute.

What procurement teams actually care about

Sure, the 0.1ms response time sounds impressive, but here’s what moves the needle: it drops into existing Rexroth control architectures without custom programming. You’ll typically save 3-5 engineering hours per installation versus third-party drives. And with 365-day warranty coverage (including accidental overvoltage – yes, really), I’ve seen plants stockpile these as “hot spares” knowing they’ll work when needed. The 50% deposit gets it moving fast – most ship within 48 hours if you order before noon EST.

Keep it humming

Mount it vertically in standard 800x600mm cabinets with 50mm clearance above – that airflow matters more than datasheets admit. Clean vents quarterly with compressed air (don’t skip this when sawdust flies in woodworking shops). Firmware updates via USB stick take 90 seconds, and I’d recommend doing them during scheduled maintenance windows. One caveat: the terminal blocks need 0.5Nm torque – over-tightening cracks the housing, which happened to a client last quarter.

Certified reliability

CE, UL 61800-5-1, RoHS 3 compliant. Full 365-day warranty covering parts and labor – no fine print about “industrial environments” excluding normal factory conditions. When you order, you’ll get the drive, mounting hardware, and a printed quick-start guide (PDFs get lost in email chains, right?). Payment’s straightforward: 50% upfront, balance before FedEx/UPS/DHL shipping – no surprises.

Reviews

There are no reviews yet.