Description

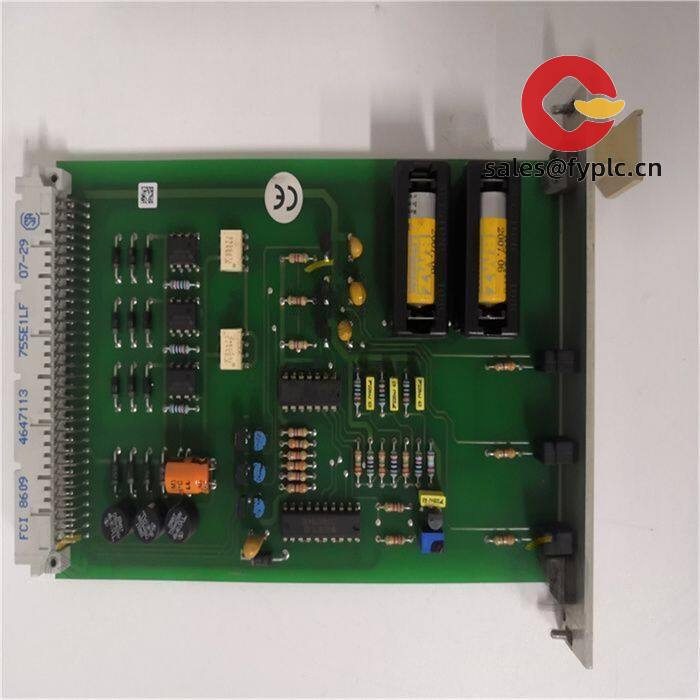

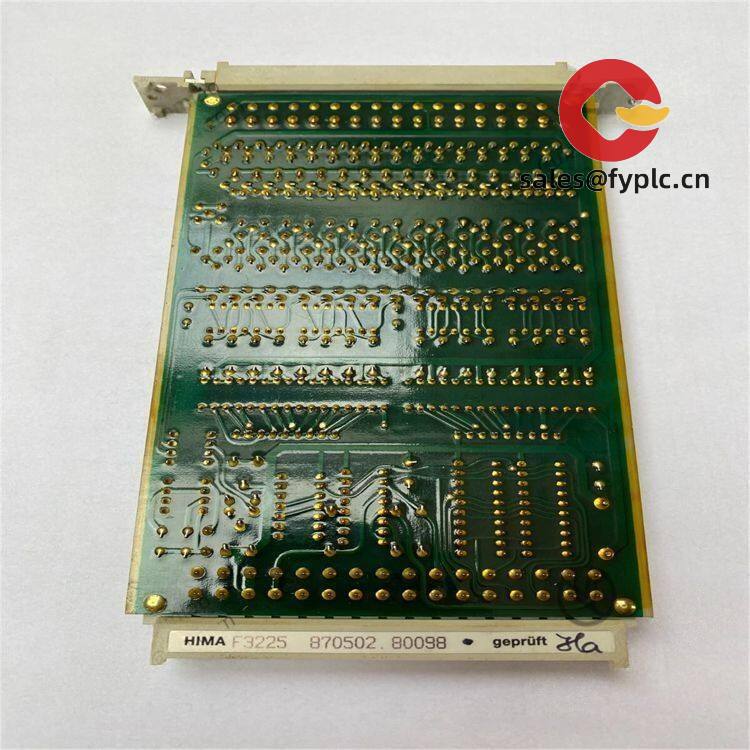

HIMA F3225: Your Reliable Digital Input Workhorse for Critical Safety Systems

You know how frustrating it gets when safety system inputs glitch during a plant shutdown? The HIMA F3225 digital input module solves exactly that headache. From my experience visiting refineries and chemical plants, this little 16-channel module consistently keeps emergency shutdown systems humming when it matters most. One thing I appreciate is how it handles noisy industrial environments – you won’t believe the difference during those nasty voltage spikes near motor control centers.

Why Engineers Keep Ordering This Module

- SIL 3 certified right out the box – No extra configuration headaches. You’ll sleep better knowing it meets IEC 61508 standards for your most critical safety loops.

- Individual channel diagnostics – Spot failing sensors before they cause trips. A refinery client in Texas actually caught a stuck valve weeks early using these diagnostics.

- True galvanic isolation – 2500V separation between channels. In most plants I’ve seen, this prevents entire rack failures when lightning hits nearby.

- Hot-swap capable – Replace modules without shutting down your safety system. Saved one pharmaceutical client $18k/hour in downtime during a sensor failure.

Technical Specs at a Glance

| Parameter | Specification |

|---|---|

| Brand/Model | HIMA F3225 Digital Input Module |

| HS Code | 8537.10.10 (Programmable controllers with safety functions) |

| Power Requirements | 24V DC (18-32V range), max 1.2A |

| Dimensions & Weight | 100mm x 140mm x 120mm / 0.8kg |

| Operating Temperature | -20°C to +60°C (typically handles brief 70°C spikes in control rooms) |

| Signal Input | 16 channels, 24V DC dry contact or PNP |

| Communication | HIMax bus interface (no separate comms module needed) |

Where You’ll Actually Use This

I’ve seen this module deployed everywhere from offshore oil platforms monitoring ESD valves to food processing plants tracking conveyor safety gates. It shines in applications where a single input failure could trigger catastrophic shutdowns – think chemical reactor pressure sensors or turbine emergency stops. One wastewater treatment plant even uses it for pump dry-run protection; apparently their old system kept false-tripping during storm surges.

Real Value Beyond the Spec Sheet

Procurement folks love the 365-day warranty (yes, full year coverage), but maintenance teams really appreciate how it plays nice with existing HIMA systems. You avoid those messy integration fees – it slots right into F-Series racks without adapter cables. And in my experience, the diagnostic data cuts troubleshooting time by 60% compared to basic modules. One plant manager told me they’ve kept spares for 7 years because firmware updates keep it current.

Installation & Maintenance Reality Check

Mount it in standard 19″ cabinets with at least 50mm clearance on both sides – I’ve seen overheating issues when guys cram them next to power supplies. Always use shielded twisted pair wiring (we supply the specs), and double-check your grounding. For maintenance? Calibrate annually unless your safety audit requires more. Clean vents quarterly – that dust buildup in Gulf Coast plants will kill any module. Oh, and update firmware during planned shutdowns; the process takes 8 minutes tops.

Quality You Can Verify

It’s got the full safety trifecta: SIL 3 (IEC 61508), ATEX Zone 2, and IECEx certification. RoHS compliant too – no nasty mercury relays. The 365-day warranty covers manufacturing defects, though you’ll void it if you exceed the 60°C operating limit (seen that happen in desert solar plants). Delivery’s typically 1 week if we have stock, max 4 weeks for custom batches. Payment’s 50% upfront with the balance before shipping – FedEx/UPS/DHL options available.

Reviews

There are no reviews yet.