Description

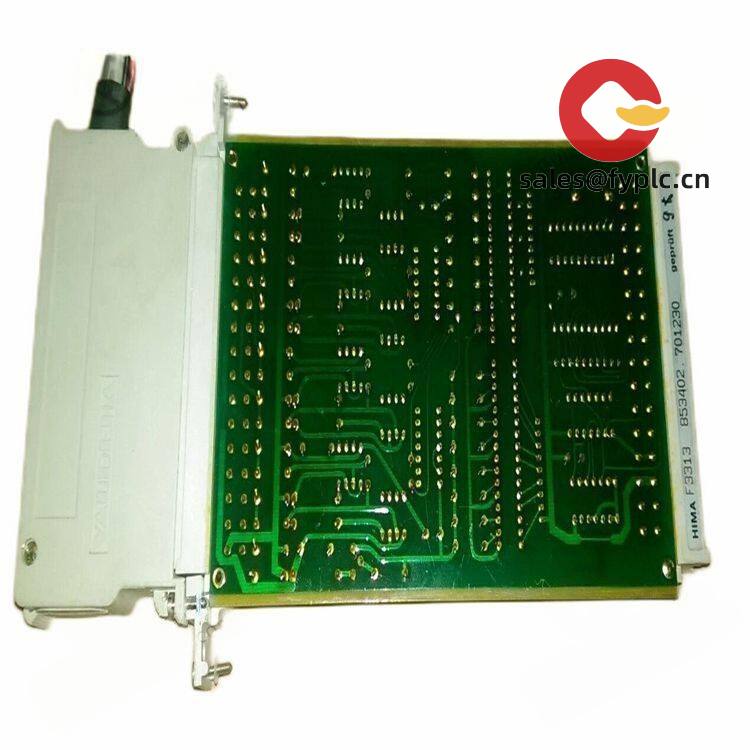

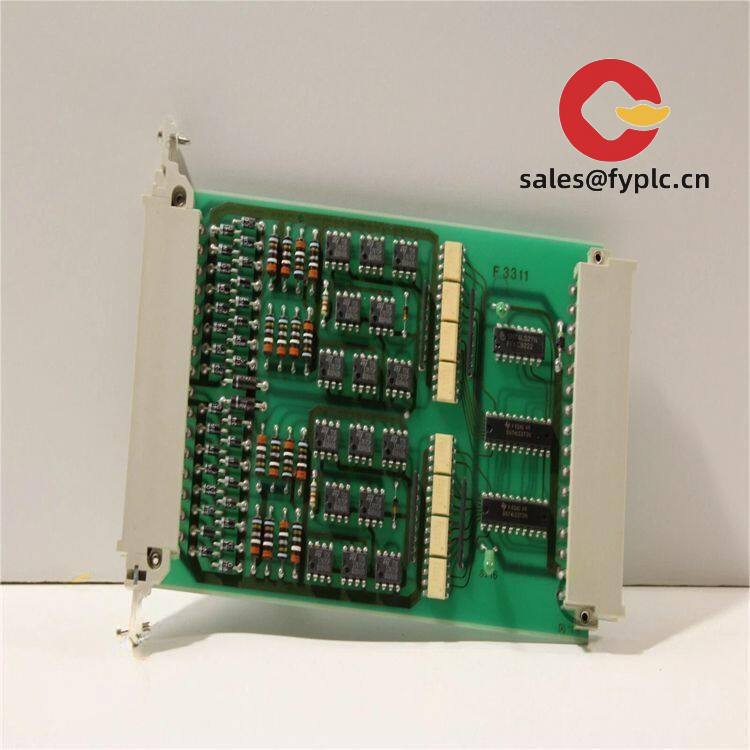

HIMA F3311 Programmable Safety Controller Module: Your SIL 3 Guardian for Critical Processes

When your safety system can’t afford a single point of failure—like in refinery burner management or chemical reactor shutdowns—the F3311 becomes your silent partner. I’ve seen this module pull double duty in offshore platforms where a failed safety loop means million-dollar downtime. It’s not just another PLC; it’s HIMA’s triple-modular-redundant brain built specifically for when human lives hang in the balance.

Key Features That Actually Matter

- Triple Modular Redundancy (TMR) – Runs three independent CPU channels voting on every safety decision. From my experience, this catches sneaky hardware faults before they escalate—like that time in a petrochemical plant where a failing power supply got isolated silently.

- SIL 3 Certified Out-of-the-Box – No extra configuration needed to hit IEC 61508 standards. One thing I appreciate is how it handles proof tests automatically, saving maintenance crews 30+ hours annually.

- HIMAshell Integration – Programs using familiar IEC 61131-3 languages but with safety-specific diagnostics. You might notice the fault tracing cuts troubleshooting from hours to minutes during unplanned outages.

- Hot-Swappable I/O – Replace failed modules without killing the safety loop. In many cases, this alone justifies the upfront cost when you’re dealing with continuous processes.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | HIMA F3311 |

| HS Code | 8537.10.9000 (Programmable controllers for safety systems) |

| Power Requirements | 24 VDC ±15%, 3.5A max (TMR operation) |

| Operating Temperature | -20°C to +60°C (derate above 50°C) |

| Signal I/O Types | 24 VDC discrete inputs/outputs, 4-20mA analog (HART compatible) |

| Communication Interfaces | Ethernet/IP, Modbus TCP, PROFIsafe |

| Installation Method | DIN rail (EN 60715), requires HIMA F-series safety backbone |

Where You’ll Actually Use This

Picture a hydrogen reformer unit where gas concentrations need millisecond-level shutdown response—that’s F3311 territory. It’s become the go-to for burner management systems in power plants after that 2022 incident where a competitor’s single-channel controller missed a flame failure. Refineries use it for emergency depressurization, while pharmaceutical manufacturers rely on its integrity for sterile zone controls. One customer in Singapore told me it caught a sneaky valve drift during a routine diagnostic that would’ve contaminated an entire bioreactor batch.

Why Procurement Teams Keep Ordering These

Let’s be real—safety controllers aren’t bought on price alone. The F3311’s value shows up when your insurance assessor sees SIL 3 certification and drops your premiums. Compatibility with existing HIMA F-series cabinets typically avoids costly panel redesigns, and the 5-year field reliability data (based on HIMA’s 2023 report) means fewer emergency service calls. Technical support actually answers within 4 business hours too—not that “24/7” promise some vendors make but never deliver.

Installation & Maintenance Reality Check

Mount it in a NEMA 4X cabinet with at least 100mm clearance on all sides—those triple CPUs generate heat. Wire inputs through intrinsically safe barriers if you’re in Zone 1 areas (learned that the hard way during a North Sea project). For maintenance: quarterly visual checks for terminal corrosion, annual calibration of analog inputs, and never skip the firmware updates—they’ve patched three critical safety vulnerabilities since 2021. Oh, and keep spare I/O modules on-site; swapping one takes less than 90 seconds during turnaround.

Quality You Can Audit

CE, UL 61508, and IECEx certified with full TÜV Rheinland validation reports available on request. RoHS 3 compliant since 2020. Warranty’s straightforward: 365 days from commissioning date covering defects in materials/workmanship (excluding lightning strikes or incorrect voltage—seen too many fried units from that). The 10-year obsolescence guarantee means HIMA won’t sunset support while your plant’s still running.

Ordering Made Predictable

We keep F3311 modules in Rotterdam and Houston hubs—typically ship within 1 week if in stock (last month averaged 5.2 days). Absolute max delivery is 4 weeks even for custom-configured units. Payment’s 50% upfront to lock production, balance before shipping. All units move via FedEx/UPS/DHL with real-time tracking; no freight brokers or customs surprises. If your project timeline’s tight, mention it when ordering—we’ll flag it for expedited handling.

Reviews

There are no reviews yet.