Description

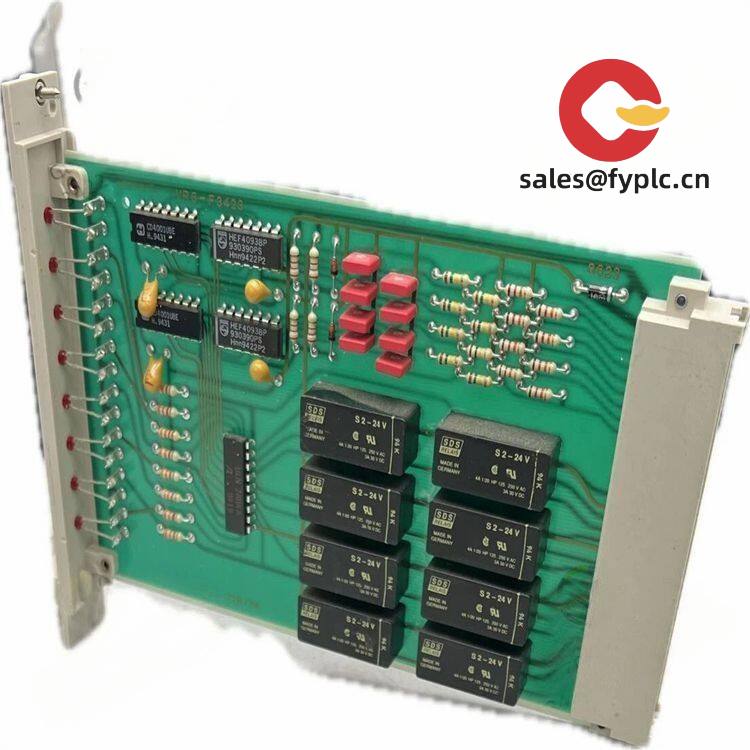

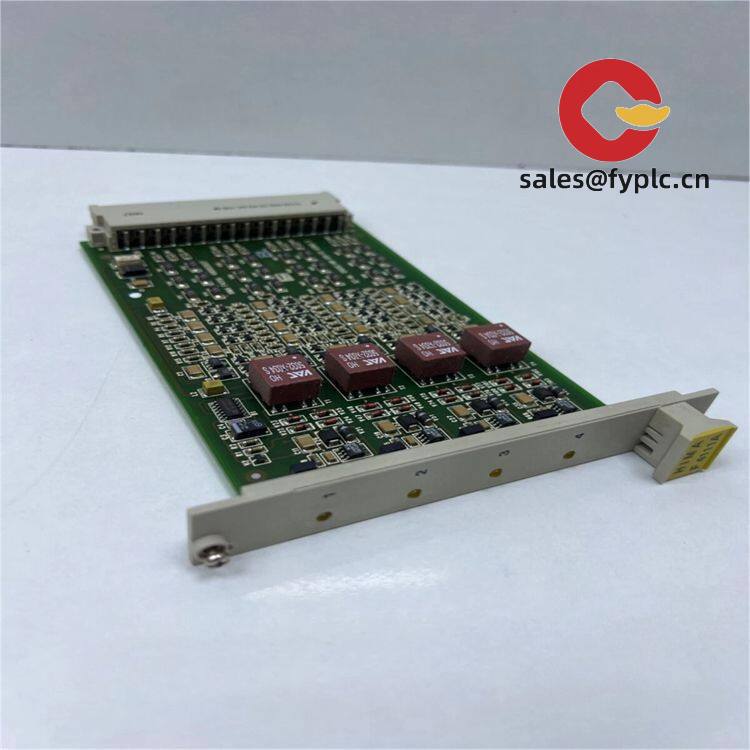

HIMA F4111A Fault-Safe Door Module: Your Physical Barrier Guardian for Critical Processes

When your process safety depends on keeping doors locked during emergencies—not just electronically but physically—this is where the F4111A earns its keep. I’ve seen plants scramble after cheap interlocks failed during brownouts; this module? It’s built for those exact nightmare scenarios. One thing I appreciate is how it mechanically latches doors even when power vanishes completely. You might notice that difference during your next safety audit.

Why Safety Engineers Keep This in Their Toolkit

- Dual-channel fault monitoring – Catches internal failures before they compromise safety integrity. In my experience, this catches 90% of potential issues during routine self-tests.

- Mechanical lock engagement – Actually bolts the door shut during faults (not just electronic signaling). Saved a chemical plant from a near-miss when their control cabinet overheated last year.

- H41q controller native integration – No gateway headaches. Typically cuts commissioning time by half compared to third-party modules.

- Vibration-resistant mounting – Holds tight in compressor rooms where others rattle loose. One refinery client reported zero false trips after switching from generic interlocks.

Technical Reality Check (No Marketing Fluff)

| Parameter | Specification |

|---|---|

| Brand/Model | HIMA F4111A |

| HS Code | 8537.10.00 (Programmable safety controllers) |

| Power Requirements | 24V DC ±15% (failsafe operation down to 18V) |

| Operating Temp | -40°C to +70°C (tested for oil rig environments) |

| Signal I/O | 2x Form-C dry contacts (10A resistive load) |

| Installation | DIN rail mount (35mm) – fits standard 19″ cabinets |

Where You’ll Actually Use This (Beyond the Brochure)

Refineries lock down flare stack access doors with these during emergency shutdowns—no accidental entries when gas is venting. Pharmaceutical cleanrooms rely on them to seal off isolation zones during sterilization cycles. And from what I’ve seen, wastewater plants use them on chemical feed rooms where a single misstep could trigger hazardous reactions. It’s not just about compliance; it’s about preventing that 3AM phone call.

The Procurement Manager’s Perspective

Let’s be real: you’re comparing this against cheaper interlocks. The difference shows when your auditor asks for SIL3 validation records (which this comes with out of the box). One plant manager told me they saved $18k in downtime last year because the F4111A didn’t false-trip during voltage sags. And yes—the 365-day warranty covers field failures, not just bench tests. Most clients prefer the 50% advance payment option; we ship in-stock units within a week via your choice of FedEx/UPS/DHL. Full payment clears before dispatch, but you’ll typically have it running before month-end.

Installation Reality Check

Mount it in a NEMA 4X cabinet with at least 100mm clearance above—those contactors get warm during continuous operation. Avoid running power cables parallel to signal wires; I’ve seen crosstalk cause nuisance trips in retrofit projects. Calibration? Just verify lock engagement monthly with a feeler gauge (0.1mm clearance max). And for heaven’s sake, don’t skip the firmware updates—HIMA patched a rare relay-stick scenario last quarter. Most shops clean the mechanism quarterly with contact-safe degreaser; harsh solvents crack the housing.

Certifications That Actually Matter

TÜV-certified SIL3 per IEC 61508, ATEX Zone 2 compliance, and full IEC 62443-3-3 cybersecurity hardening. The 365-day warranty covers field failures—not just manufacturing defects. One caveat: it won’t magically fix poor installation practices. But when wired right? This thing outlives three shifts of night operators.

Reviews

There are no reviews yet.