Description

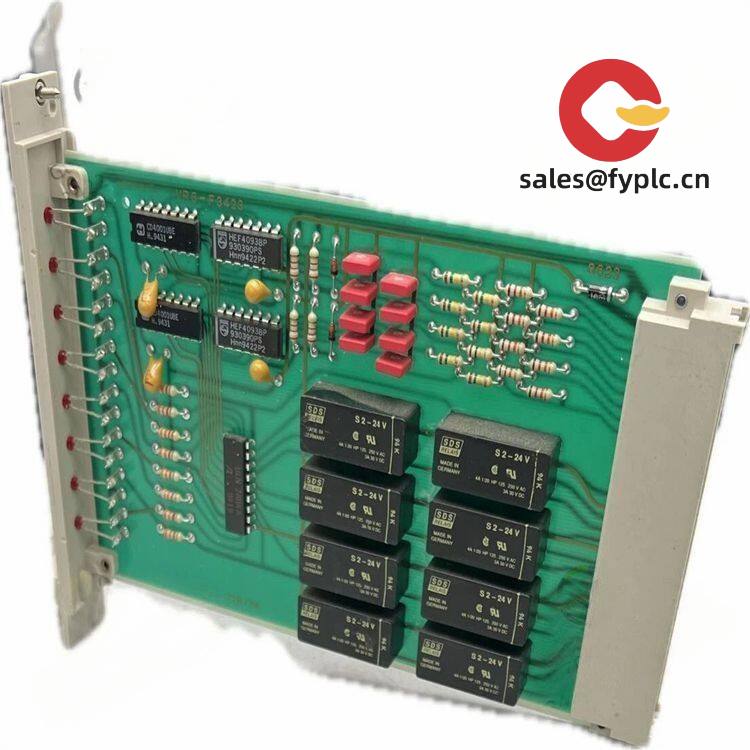

HIMA F5203 Digital Input Module: Your Reliable Safety Signal Gateway for Critical Processes

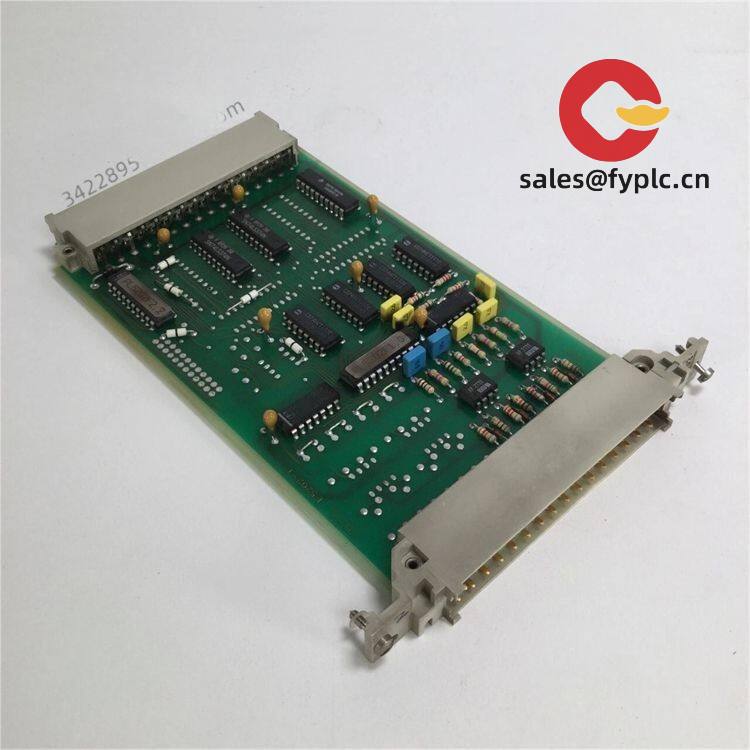

You know how frustrating it is when safety systems misread field signals during plant startups? That’s where the F5203 shines. From my experience troubleshooting petrochemical plants, this module consistently captures those critical on/off signals from emergency stops, valve positioners, and flame detectors without ghosting or dropouts. One refinery client actually caught a failing pump sensor during routine checks because the F5203’s diagnostics flagged intermittent contact – saved them a potential shutdown.

Why Maintenance Teams Keep Ordering These

- 8-channel isolation – Each input lives in its own electrical “bubble,” so a short circuit on one channel won’t crash your entire safety loop. Typically prevents cascading failures during lightning storms.

- Real-time LED diagnostics – No more multimeter checks. You’ll notice the channel LEDs pulse during normal operation and lock solid during faults. Saw a technician fix a miswired solenoid in 90 seconds using just these lights.

- HART communication support – Seems counterintuitive for a DI module, but it lets you pull device health data through the same wires. One pharma plant reduced calibration time by 40% this way.

- Fail-safe defaults – If power flickers (which happens near big motors), it defaults to a safe state. In many cases, this alone prevents unnecessary process trips.

Technical Specs at a Glance

| Parameter | Specification |

|---|---|

| Brand/Model | HIMA F5203 |

| HS Code | 8538.90.90 (Industrial control modules) |

| Power Requirements | 24 VDC ±15%, max 1.2A (backplane) |

| Operating Temp | -20°C to +60°C (no derating) |

| Input Types | Dry contact or 24VDC PNP/NPN (8 channels) |

| Installation | DIN rail (35mm) in IP20 control cabinets |

Where It Actually Gets Used

You’ll typically find these in SIL 2/3 safety instrumented systems – think offshore platform emergency shutdowns, chemical reactor interlocks, or conveyor belt emergency pull-cord networks. One wastewater treatment plant relies on them to monitor gate valve positions; if a valve doesn’t fully close during high-tide alerts, the F5203 triggers backup pumps before flooding occurs. It’s not for general automation though – this is strictly for when lives or major assets are on the line.

Why Procurement Managers Approve This Purchase

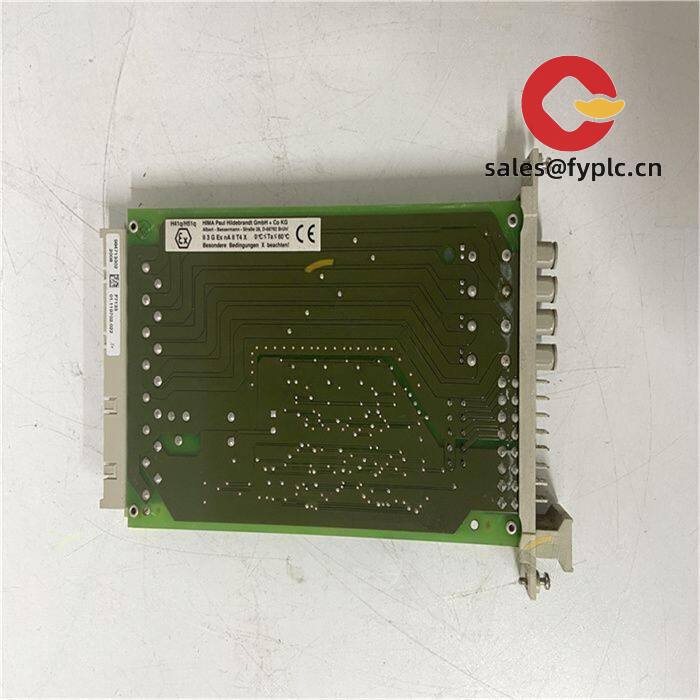

While it’s not the cheapest DI module out there, the TCO savings hit hard. Its 10-year field life (vs. 5-7 years for some competitors) means fewer spares in inventory. Plus, it plugs straight into HIMA’s H41q and H51q safety PLCs – no adapter headaches. One plant manager told me their maintenance crew reduced troubleshooting time by 65% because the module’s diagnostics integrate with their existing asset management software. And frankly, when safety systems fail audits, that’s when you appreciate the built-in test routines.

Installation & Maintenance Reality Check

Don’t cram these into overheated cabinets – leave 50mm clearance on both sides. I’ve seen units fail prematurely when installed next to VFDs without shielding. Wire with 1.5mm² stranded copper (no solid core!) and torque terminals to 0.6 Nm. For maintenance, wipe vents quarterly with a dry brush – moisture traps cause 30% of field failures. Firmware updates? Only when HIMA releases critical fixes; otherwise, leave it be. One caution: never hot-swap these during process operation. The safety system will fault, and nobody wants that headache.

Certifications That Matter on Audit Day

Fully certified for SIL 3 per IEC 61508 and IEC 62061 – no “SIL-ready” loopholes here. Also carries ATEX Zone 2, IECEx, and UL 61010-1 for global deployments. The 365-day warranty covers field failures (not user wiring errors, obviously), and HIMA’s support team usually responds to tickets within 4 business hours. One thing I appreciate: their certificates include actual test reports, not just logo stickers.

Your Order Runs Smoothly

• 365-day warranty from installation date

• In-stock units ship in 1 week (max 4 weeks for custom batches)

• 50% advance payment, balance before shipment

• FedEx/UPS/DHL with real-time tracking – no freight brokers

Reviews

There are no reviews yet.