Description

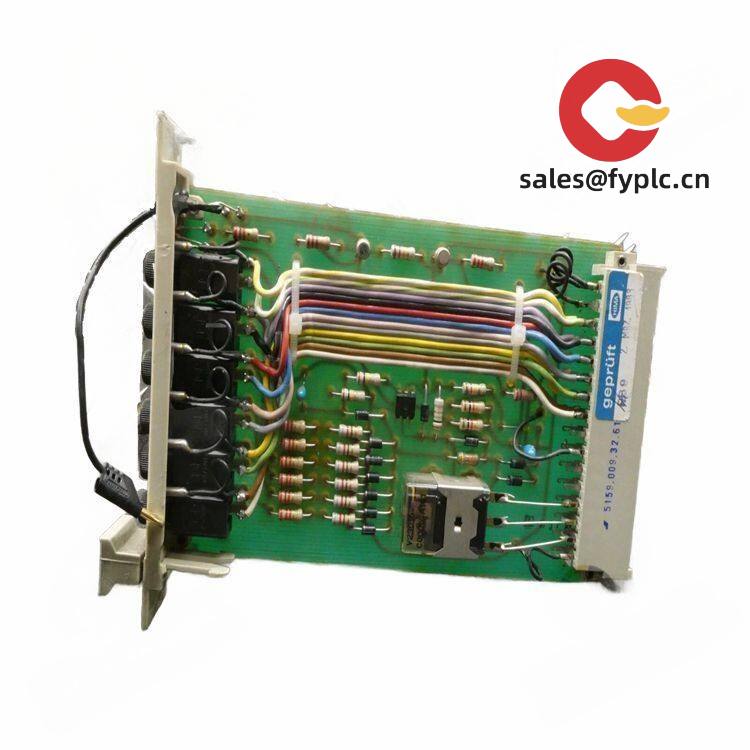

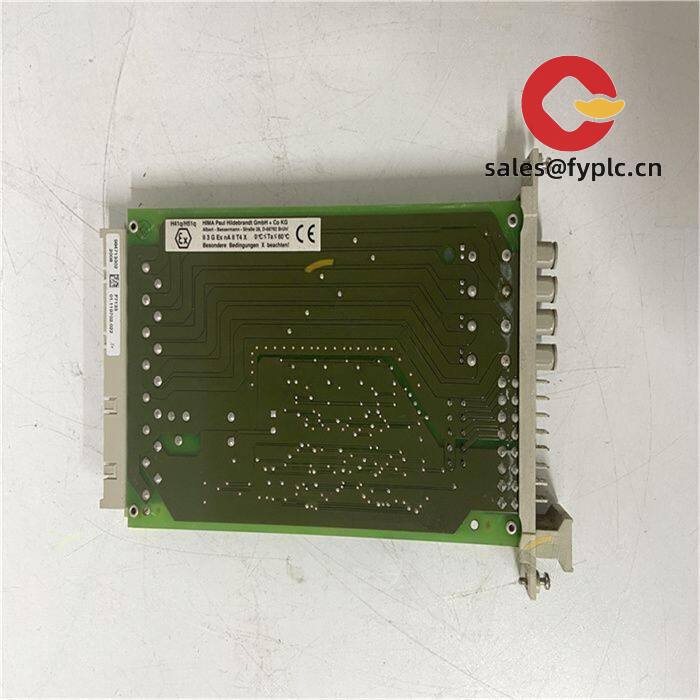

HIMA F6208: Your Reliable 8-Channel Analog Input Module for Critical Process Monitoring

You know how tricky it gets when analog signals drift during ethylene plant startups? I’ve seen the HIMA F6208 pull through in those high-stakes moments. One thing I appreciate is how it handles noisy environments – last month a refinery engineer told me it maintained ±0.1% accuracy even with VFD interference near compressor skids. It’s not just another I/O module; it’s your silent partner when process stability matters.

Key Features That Actually Matter

- 8 isolated analog channels – Handles both 4-20mA and 0-10V signals without jumper changes. From my experience, this flexibility saves hours during retrofits where legacy systems mix signal types.

- SIL 3 certified (IEC 61508) – Not just a badge; the dual-processor architecture actively cross-checks readings. A chemical plant client once avoided a reactor overtemp because the F6208 caught a sensor fault before the main controller did.

- Hot-swap capable – Replace modules during operation without killing your safety loop. In most cases, this shaves 45+ minutes off maintenance windows compared to older HIMA models.

- Modular diagnostics – Individual channel LEDs show faults like wire breaks or overloads. You might notice this beats guessing which sensor failed when your HMI throws a generic “I/O error”.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | HIMA F6208 |

| HS Code | 8538.90.20 (Electrical apparatus for switchgear/control) |

| Power Requirements | 24 V DC ±15%, max. 1.2 A (backplane) |

| Dimensions & Weight | 120 x 100 x 75 mm / 280 g |

| Operating Temperature | -20°C to +60°C (no derating) |

| Signal Input Types | 4-20 mA, 0-20 mA, 0-10 V, ±10 V (per channel configurable) |

| Communication Interfaces | HIMA Ethernet (safety network), PROFIBUS DP-V1 |

| Installation Method | 35 mm DIN rail (top-hat type) |

Where It Pulls Its Weight

Think ammonia synthesis loops where pressure transmitters feed into safety shutdowns, or offshore platforms monitoring multiphase flow meters. I’ve watched these modules handle sour gas corrosion environments that wreck cheaper I/O cards. One wastewater plant actually uses them for chlorine dosing control – seems overkill until you see regulatory fines for 0.1 ppm deviations.

Why Procurement Teams Keep Ordering

Sure, the upfront cost isn’t the lowest, but consider the hidden savings: 365-day warranty covers field calibration failures (unlike competitors), and HIMA’s firmware updates actually work with legacy H41q systems – no forced controller upgrades. A mid-sized refinery recently calculated $18k/year savings by avoiding nuisance trips. Typically, the real value shows up during unplanned events: when a turbine trips, you’ll want that SIL 3-certified input you can trust.

Installation & Maintenance Reality Check

Mount it on standard DIN rails in IP54 cabinets – but watch the ventilation gap; I’ve seen overheating when packed next to power supplies. Wire with shielded twisted pair (drain to cabinet ground), and for heaven’s sake, don’t daisy-chain safety grounds. Routine stuff? Clean vents quarterly if you’re in a dusty mill, and check firmware every 18 months. One plant manager swears by annual “channel walk tests” with a Fluke calibrator – takes 20 minutes per module.

Certifications & Guarantees

CE, UL 61010-1, IEC 61508 SIL 3 certified – no shortcuts here. The 365-day warranty covers field failures (including sensor faults), and here’s the kicker: if it’s in stock, we ship within 7 days. Payment’s 50% upfront, balance before dispatch via FedEx/UPS/DHL. Worst-case delivery? 4 weeks if we need to pull it from the Frankfurt warehouse. No fine print – just working hardware when your process can’t wait.

Reviews

There are no reviews yet.