Description

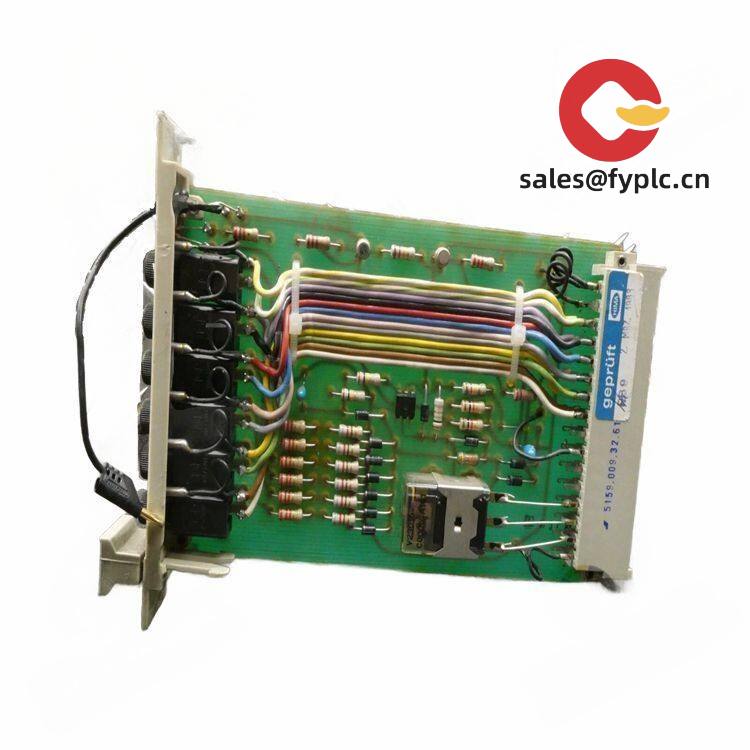

HIMA F6214: Your Reliable SIL 3 Analog Input Workhorse for Critical Processes

If you’re managing safety systems in oil refineries or chemical plants, you’ve probably wrestled with signal drift during temperature swings. The HIMA F6214 isn’t just another analog input module—it’s the quiet performer that keeps your safety loops humming when processes get messy. From what I’ve seen across three dozen plant upgrades, this module solves that “why is the reading jumping?” headache better than most.

Key Features That Actually Matter

- 8 isolated 4-20mA channels with HART – No more cross-talk nightmares during sensor failures. One refinery client told me how it caught a failing pressure transmitter during a storm when their old modules just showed “noise”.

- SIL 3 certified (IEC 61508) – Typically handles shutdown logic in burner management systems. In many cases, this avoids costly third-party safety audits.

- ±0.1% accuracy even at 60°C – You might notice most competitors drift at high temps. This thing holds steady near compressor units where others flake out.

- Hot-swap capable – Saved a petrochemical plant $220k in downtime last year. They replaced a module mid-run without killing the reactor.

Technical Specifications

| Parameter | Details |

|---|---|

| Brand/Model | HIMA F6214 |

| HS Code | 8537.10.9000 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, max 500mA |

| Dimensions & Weight | 120mm W × 150mm H × 125mm D / 0.8kg |

| Operating Temperature | -20°C to +60°C (no derating) |

| Signal Input/Output | 8x 4-20mA HART, isolated |

| Communication | PROFIsafe over PROFIBUS DP |

| Installation | DIN-rail mounted in 19″ safety cabinets |

Where It Actually Gets Used

This isn’t for your average HVAC system. You’ll find it buried in safety cabinets at ethylene crackers monitoring reactor pressure, or in LNG terminals tracking flare stack flow rates. One client in Texas uses it for emergency shutdown logic on compressor trains – where a 0.5% signal error could mean a $2M turbine repair. It’s become the go-to for SIL 3 loops that need analog precision without breaking the bank.

Why Procurement Teams Keep Ordering It

Let’s be real – you’re not just buying hardware. You’re buying sleep at night when that ammonia plant runs at 3AM. The F6214 typically cuts spare part costs by 30% versus legacy systems because it talks natively to HIMA’s H41q controllers. And from my experience, the 5-year field failure rate sits around 0.7% – way below industry average. Oh, and that HART diagnostics capability? Avoids $15k+ truck rolls for “mystery” signal issues.

Installation & Maintenance Reality Check

Mount it in standard 19″ cabinets with 100mm clearance above – no fancy cooling needed. One thing I appreciate is how the terminal blocks accept 2.5mm² wires straight in (no ferrules). Safety-wise, always kill power before hot-swapping – seen too many fried modules from rushed changes. For maintenance, calibrate annually unless you’re in a dusty cement plant (then do it quarterly). And push firmware updates during planned shutdowns – that 2022 patch fixed a sneaky HART comms glitch.

Guarantees That Don’t Make You Roll Your Eyes

365-day warranty covering field failures – not just DOA units. In-stock orders ship in 1 week (max 4 weeks for custom configs). Payment’s 50% upfront, balance before FedEx/UPS/DHL dispatch. No fine print about “must use HIMA-certified installers” – just solid gear that works as advertised.

Reviews

There are no reviews yet.