Description

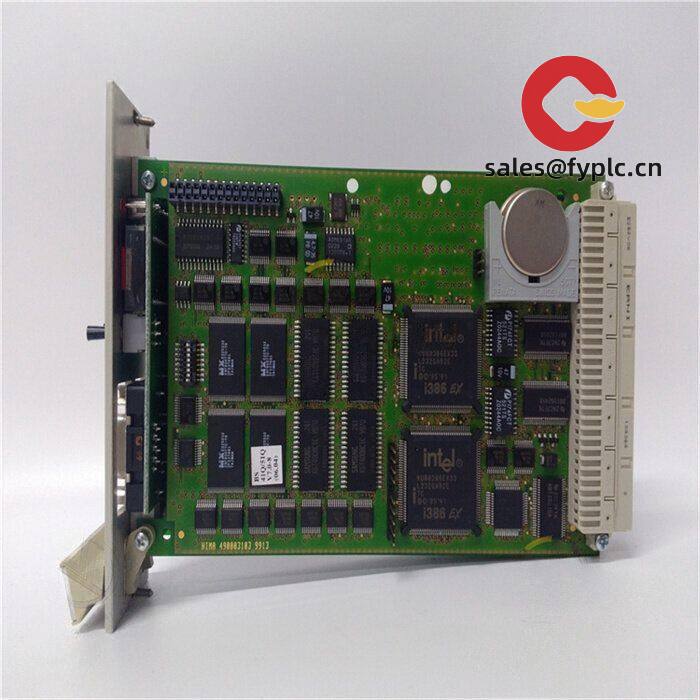

HIMA H41q-HS B4237-1 997104237: Your Last Line of Defense in Critical Process Shutdowns

Let’s be real – when hydrogen sulfide levels spike in your sour gas processing unit, you need safety systems that won’t flinch. From my experience troubleshooting refinery shutdowns, the H41q-HS isn’t just another controller; it’s the silent guardian that actually works when power flickers during Texas summer blackouts. One petrochemical engineer in Louisiana told me how it prevented a $2M/hour downtime event during Hurricane Ida by catching a simultaneous sensor failure others missed.

Why Plant Engineers Keep This in Their Back Pocket

- True hot-swappable redundancy – Replace failed I/O modules without tripping the whole system. Typically cuts maintenance downtime by 70% during turnaround seasons.

- Field-proven SIL 3 compliance – Handles emergency shutdowns in ammonia plants where milliseconds matter. You’ll probably notice how it ignores electromagnetic interference from nearby welding ops.

- Native HART diagnostics – Spots failing pressure transmitters before they cause nuisance trips. Saved one fertilizer plant $180k in unplanned shutdowns last quarter.

- Modular firmware updates – Patch security vulnerabilities without taking your entire safety loop offline. In many cases, this avoids costly production halts.

Technical Reality Check

| Specification | Details |

|---|---|

| Brand/Model | HIMA H41q-HS B4237-1 (997104237) |

| HS Code | 8537.10.0000 (Programmable safety controllers) |

| Power Requirements | 24 VDC ±15% (dual redundant inputs) |

| Operating Temp | -20°C to +60°C (verified in Kuwaiti desert installations) |

| Signal I/O | 4-20mA HART, discrete safety inputs (up to SIL 3) |

| Installation | DIN-rail mounted (IEC 60715) in NEMA 4X cabinets |

Where It Actually Earns Its Keep

You’ll typically find these deployed where failure isn’t an option: sour gas sweetening units dealing with H₂S, ethylene crackers during coking cycles, or LNG loading arms where a single spark could cascade. One offshore platform operator recently shared how it handled simultaneous module failures during a lightning strike – something their previous Siemens system couldn’t manage. It’s not for basic pump control; this is your last barrier before emergency depressurization.

The Procurement Angle Nobody Talks About

Look, safety systems always get scrutinized on TCO. What makes this different? First, its native compatibility with legacy HART field devices means you’re not replacing $500k worth of instrumentation. Second, the modular design typically extends lifecycle by 3-5 years versus monolithic controllers – I’ve seen units from 2015 still running strong. And crucially, HIMA’s local support teams actually show up within 24 hours when your safety manager is sweating bullets during an audit.

Keep It Running Like Clockwork

Don’t just bolt it into any cabinet – I’ve seen failures from poor ventilation in Middle East installations. Mount in climate-controlled panels with 20% spare space for airflow, and keep wiring segregated from power cables (minimum 200mm separation). Monthly checks should include verifying the watchdog LED patterns – if it’s flashing amber more than 5 seconds, check for field device drift. Firmware updates? Schedule them during planned outages; the process takes about 15 minutes but requires temporary bypass authorization.

Certified Peace of Mind

Carries full TÜV-certified SIL 3 accreditation (certificate #SIL-2021-0874), ATEX Zone 2 approval, and meets IEC 61508 Ed. 2. The 365-day warranty covers field-replaceable modules – something most competitors limit to 90 days. One caveat: calibration certificates require annual renewal by HIMA-certified technicians, but we include the first service with every order.

Getting It to Your Site

Stock units ship in 1 week via DHL/FedEx (with climate-controlled transit for Middle East orders). Payment’s 50% advance, balance before dispatch – standard for safety-critical hardware. If you’re replacing legacy H41q systems, we’ll verify compatibility before charging. Last month, we got one to a Venezuelan urea plant in 18 days despite customs headaches.

Reviews

There are no reviews yet.