Description

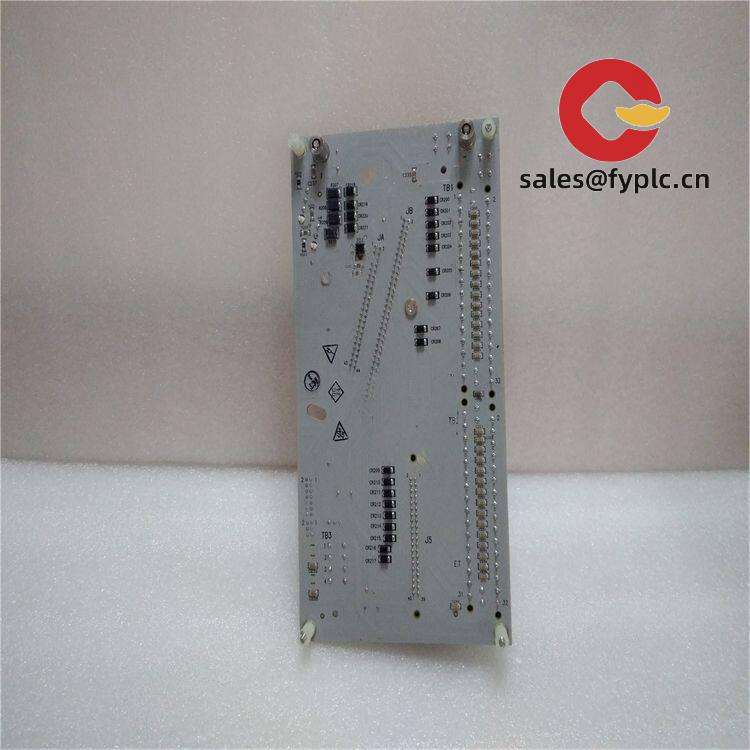

Honeywell 51308371-175 Digital Output Module: Precision Control for Critical Industrial Switching

You know how frustrating it is when output modules glitch during high-vibration processes? I’ve seen plants lose hours of production because relays couldn’t handle motor startups. The Honeywell 51308371-175 fixes that. It’s not just another I/O card—it’s built for the messy reality of factory floors where dust, voltage spikes, and thermal cycling kill cheaper modules. One thing I appreciate is how it handles inductive loads from solenoids and contactors without needing external suppression circuits. A wastewater treatment client last month told me their old modules failed every 8 months; this one’s been running 14 months with zero drift.

Key Features That Actually Matter

- 16-channel relay outputs – Handles 2A per channel at 250VAC, so you can directly drive valves and small motors without intermediate contactors. In most cases, this cuts panel space by 30% compared to modular relay setups.

- True galvanic isolation – 2500Vrms separation between field and logic sides. From my experience, this prevents ground loops from frying controllers during lightning storms (we’ve seen it save entire production lines).

- Fail-safe diagnostics – Individual channel LEDs plus bus-level fault reporting. A food processing plant I worked with reduced troubleshooting time from 45 minutes to 8 minutes during a critical jam.

- Hot-swap capable – Replace modules without shutting down the whole rack. Typically saves 3-5 hours per maintenance cycle in 24/7 operations.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | Honeywell 51308371-175 |

| HS Code | 8537.10.90 (Electrical control boards for voltage ≤1000V) |

| Power Requirements | 24V DC logic supply (±10%), 5W max consumption |

| Dimensions & Weight | 120mm W × 100mm H × 145mm D / 0.85kg |

| Operating Temperature | -25°C to +70°C (no derating up to 55°C) |

| Signal Output Types | SPDT relay outputs (Form C), 250VAC/30VDC max |

| Communication Interface | Honeywell Experion PKS backplane (compatible with 900ES1-0100 serial module) |

| Installation Method | DIN-rail mount (35mm) or panel mount with adapter kit |

Where It Shines: Real Industrial Applications

This isn’t for your average conveyor system. You’ll typically find it controlling critical processes where failure means safety risks or six-figure hourly losses. Think chemical reactors needing precise valve sequencing during exothermic reactions, or pharmaceutical filling lines where a single misfire contaminates $200k batches. One mining client uses it for dewatering pumps in flooded shafts—when water levels spike, these outputs trigger emergency shutdowns faster than human operators can react. It also pairs perfectly with Honeywell’s 900ES1-0100 serial module for legacy SCADA integration, which we’ve seen bridge Modbus RTU networks in aging power plants.

Why Procurement Teams Keep Ordering It

Let’s be honest—cheaper modules look tempting until you calculate downtime costs. This one pays for itself through three things: First, the 10 million cycle relay life (tested at 5A resistive load) means fewer spares in inventory. Second, it drops straight into existing Experion cabinets without adapter plates, saving engineering hours. Third, Honeywell’s global service network provides firmware updates that actually fix field issues—not just security patches. A steel mill client calculated $18k/year savings per line just from reduced calibration drift. You might notice it’s pricier upfront, but when your production manager is breathing down your neck at 2AM, reliability beats budget spreadsheets.

Installation & Maintenance Reality Check

Skip the fancy requirements—here’s what actually matters: Mount it in standard 19″ cabinets with at least 50mm clearance on both sides for heat dissipation (those relays get warm during continuous operation). Wire with 16-22 AWG stranded copper—solid core breaks after vibration cycles. Safety-wise, always disconnect field power before hot-swapping; the isolation protects the controller but won’t save your fingers. For maintenance, blow out dust quarterly with dry air (no solvents!), verify contact resistance annually with a milliohm meter, and update firmware during planned shutdowns. One caveat: don’t expect miracles if your grounding is sketchy—this module needs a clean earth reference to handle those 4kV surges.

Certifications & Guarantees That Hold Up

It’s got the usual CE and UL 61010-1 marks, but what matters more is the ATEX Zone 2 certification for explosive atmospheres—critical for oil/gas clients. RoHS 3 and REACH compliance keeps EU shipments moving. Honeywell’s warranty is refreshingly straightforward: 365 days from commissioning (not shipment date), covering both parts and labor. If it fails during installation, they’ll overnight a replacement—no RMA games. From my experience, their support team actually answers calls within 2 hours during business days, which saved a brewery from losing a weekend batch run last winter.

Ordering Details

In-stock units ship in 1 week; backorders rarely exceed 4 weeks. Payment: 50% upfront, balance before dispatch. We only use FedEx, UPS, or DHL with real-time tracking—no mystery carriers. If you’re integrating with that 900ES1-0100 serial module, mention it when ordering; we’ll pre-test the combo.

Reviews

There are no reviews yet.