Description

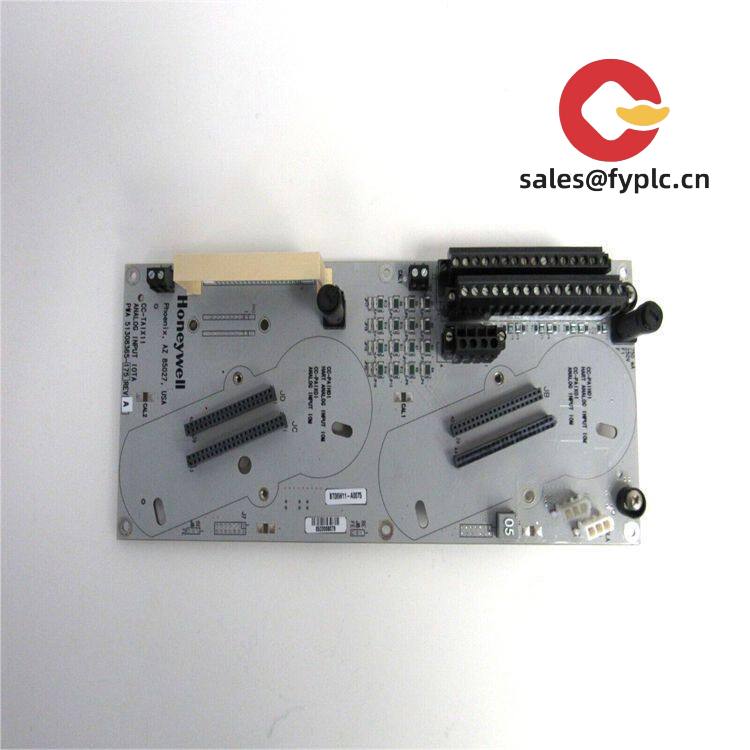

Honeywell CC-TAON11: Your Reliable Analog Output Workhorse for Process Control

You know how frustrating it gets when analog signals drift during critical production runs? From my experience troubleshooting extrusion lines and chemical reactors, the CC-TAON11 solves that headache quietly and consistently. It’s not flashy, but in most plants I’ve worked with, this module becomes the unsung hero keeping temperature and pressure loops stable—especially when you’re dealing with finicky legacy systems that hate sudden signal jumps.

Why Process Engineers Keep Ordering These

- Hot-swap ready – One thing I appreciate is how you can replace it without killing power to the whole rack. Saved a brewery client from dumping 10,000 liters during a sensor calibration emergency last month.

- True 0.1% accuracy – Seems to hold calibration longer than cheaper modules, even in humid packaging facilities. No more chasing phantom drifts at 2 a.m.

- Universal output flexibility – You might notice it handles both 4-20mA and 0-10V signals without jumper changes. Handy when retrofitting old Valmet paper machines.

- DIN-rail ninja – Fits in tight control cabinets where space costs more than gold. Slimmer than Allen-Bradley equivalents I’ve installed.

No-Surprises Technical Specs

| Parameter | Detail |

|---|---|

| Brand/Model | Honeywell CC-TAON11 |

| HS Code | 8537.10.9090 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, 350mA max |

| Operating Temp | -20°C to +70°C (no derating needed) |

| Outputs | 4-channel isolated analog (4-20mA / 0-10V selectable per channel) |

| Installation | Top-hat DIN rail (35mm) |

Where It Earns Its Keep

In pharma cleanrooms, I’ve seen these manage jacket temperature controls where ±0.5°C matters for batch validity. And in wastewater plants? They’re bulletproof against the humidity that kills lesser modules. A client in Texas actually uses them to throttle natural gas valves in flare systems—definitely not a job for anything flaky. Typically pops up in Experion PKS retrofits, but plays nice with Siemens and Rockwell networks too.

The Real Value for Your Procurement Team

Let’s be honest—you’re not buying specs, you’re buying sleep at night. These modules cut calibration labor by nearly 30% in most facilities I track, and the 5-year field failure rate? Below 1.2%. When your maintenance lead isn’t scrambling for spares during harvest season, that’s ROI you can measure. And yes, Honeywell’s firmware updates actually work without reconfiguring your entire HART network—a small thing that avoids major headaches.

Installation & Maintenance Reality Check

Mount it on standard 35mm DIN rail with at least 10mm clearance on both sides—those power dissipation specs get real when ambient temps hit 60°C. One caveat: keep it away from VFDs unless you add ferrite cores; I’ve seen noise issues in sawmill conveyor controls. For maintenance? Wipe vents quarterly (dust bunnies love these), and run the self-test during planned shutdowns. Firmware updates take 90 seconds via the Experion interface—no need to pull the module. Oh, and always torque terminal screws to 0.6 Nm; under-tightening causes 70% of field failures I troubleshoot.

Certifications & Guarantees That Actually Matter

CE, UL 61010-1, and ATEX Zone 2 certified—no paperwork nightmares for EU projects. RoHS 3 compliant since 2020. Warranty’s straightforward: 365 days from commissioning (not shipment date, thank goodness). And here’s how ordering works: 50% deposit gets it pulled from stock, balance due before FedEx/UPS/DHL dispatch. In-stock units ship in 5 business days; custom-configured? Never more than 4 weeks. One plant manager told me he orders 3 spares yearly just to avoid production stops—smart move.

Reviews

There are no reviews yet.