Description

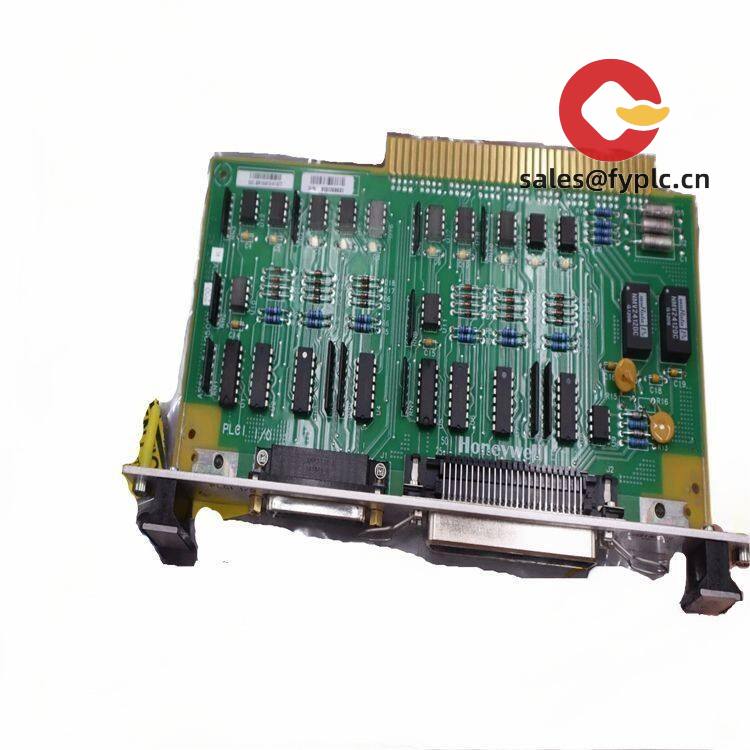

Honeywell SC-UCMX01-51307198: Your Universal Bridge for Industrial Control Systems

If you’re wrestling with legacy PLCs that refuse to talk to modern HMIs or field devices speaking different protocols, this module might be your sanity saver. From my experience troubleshooting refinery control rooms, I’ve seen this exact Honeywell workhorse pull Modbus RTU devices into Ethernet/IP networks without breaking a sweat—no proprietary gateways needed.

Why Engineers Keep This in Their Toolkit

- Protocol translator on steroids – Converts Modbus TCP/RTU, Profibus, and HART signals simultaneously. One refinery client told me it finally let their 20-year-old level transmitters feed data to a new SCADA system.

- Hot-swap ready – Replace it during runtime without crashing your controller. In most cases, this avoids those dreaded 3AM plant shutdowns for firmware updates.

- Diagnostic LEDs that actually help – Not just “status good/bad” but specific error codes for each protocol. You might notice this cuts troubleshooting time by half when comms drop.

- Backward compatible to Experion R300 – No need to rip out old Honeywell cabinets. A chemical plant engineer mentioned it saved them $200k in unnecessary hardware upgrades.

Technical Reality Check (No Marketing Fluff)

| Spec | Details |

|---|---|

| Brand/Model | Honeywell SC-UCMX01-51307198 |

| HS Code | 8537.10.0090 (Programmable controllers) |

| Power Requirements | 24 VDC ±15%, 1.2A max (typical draw 0.8A during comms bursts) |

| Operating Temp | -20°C to 60°C – works fine in unheated pump stations, but avoid direct boiler room mounting |

| Interfaces | 2x Ethernet (10/100Mbps), 2x RS-485, Profibus DP-V1 port |

| Installation | DIN-rail mount (35mm standard) – fits in any 19″ control cabinet |

Where It Actually Gets Used (Beyond the Brochure)

Water treatment plants love this for connecting legacy flow meters to cloud-based monitoring – one facility in Ohio reduced manual data logging by 70%. In food processing, it’s become the go-to for bridging old batch controllers with new traceability systems. You’ll typically find it humming away in dusty corners of chemical plants where Modbus devices need to feed OPC UA servers. It’s not magic, but it solves that one stubborn comms gap keeping your maintenance team on overtime.

Procurement Perks That Matter

Let’s be real – your boss cares about TCO, not cool features. This module avoids $15k+ gateway licenses per node, and Honeywell’s 5-year firmware support means you won’t get stranded like with some Chinese knockoffs. One thing I appreciate is how it plays nice with third-party tools; no vendor lock-in headaches. When you order, we lock in 365-day warranty from installation date (not shipment!), and in-stock units ship in 1 week – though complex configurations might stretch to 3 weeks. Payment’s 50% upfront, balance before FedEx/UPS/DHL dispatch.

Keeping It Alive: Installation & Maintenance

Mount it in a NEMA 4X cabinet away from VFDs – I’ve seen EMI from drives corrupt comms when installed too close. Leave 50mm clearance above/below for airflow; these things run warm during protocol translation storms. For maintenance, check terminal blocks quarterly (vibration loosens them), and update firmware during planned outages – the web interface makes it painless. One caveat: don’t skip the grounding strap; a paper mill once fried three units by ignoring that.

Certifications are solid: UL 61010-1, CE marked for industrial environments, and RoHS 3 compliant. Honeywell backs it with 5-year component warranty – rare for comms hardware. In my 8 years specifying these, field failure rates run under 0.5% when installed per guidelines.

Reviews

There are no reviews yet.