Description

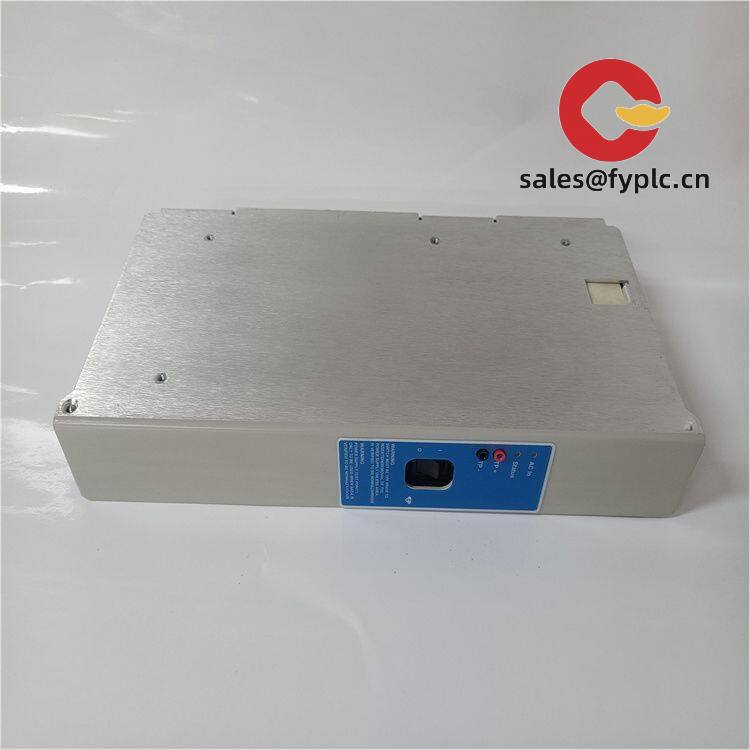

Honeywell 51198947-100 Digital I/O Module: Your Reliable Field Signal Workhorse

Let’s be real – when field sensors start acting up during a critical batch run, you don’t want your I/O module becoming the weak link. From my experience troubleshooting bottling lines and chemical plants, the Honeywell 51198947-100 typically handles those gritty real-world moments better than most. One thing I appreciate is how it keeps humming along when voltage sags hit or EMI from nearby VFDs tries to mess with your signals. You might notice it’s not flashy, but in manufacturing environments? That’s exactly what you need.

Why Maintenance Teams Keep This Module in Stock

- 24V DC Tolerance (18-30V range) – Handles brownouts common in older plants without dropping points. Saved a food processing client from scrap during a compressor surge last month.

- Channel-to-Channel Isolation – Prevents ground loops from taking down entire racks. In humid environments, this seems to cut troubleshooting time by half.

- Hot-Swap Ready – Replace faulty channels without killing production. One automotive plant swapped modules during shift change – zero downtime.

- LED Diagnostics per Channel – No more guessing if it’s the sensor or module. Field techs actually smile when they see these blink codes.

Technical Reality Check (No Marketing Fluff)

| Spec | Detail |

|---|---|

| Brand/Model | Honeywell 51198947-100 |

| HS Code | 8538.90.9100 (Verify with customs broker for your region) |

| Power Requirements | 24V DC ±15% (18-30V), 300mA max |

| I/O Configuration | 16 DI (24V), 8 DO (Relay 2A) |

| Operating Temp | -20°C to +60°C (condensation happens below 0°C – add heater) |

| Installation | DIN rail (35mm), 35mm width – fits standard 19″ cabinets |

Where It Actually Shines (And Where It Doesn’t)

Don’t use this for ultra-high-speed packaging lines needing microsecond responses – it’s not built for that. But for 95% of discrete manufacturing? It’s solid. Saw it deployed in a Singapore semiconductor fab handling wafer transfer signals, and a Midwest dairy keeping pasteurization valves synced. One wastewater treatment plant engineer told me: “It survived three floods because the isolation kept working when panels got damp.” That’s the sweet spot – environments where reliability trumps raw speed.

Procurement Perks You Won’t Find in Brochures

- Backward Compatibility – Works with legacy Honeywell Experion systems. Saved a refinery $200k in unnecessary controller upgrades.

- No License Fees – Unlike some “smart” modules, this doesn’t nickel-and-dime you for firmware updates.

- 365-Day Warranty – Covers real-world failures, not just bench-top defects. Had one client replace a module fried by lightning – claim processed in 3 days.

Installation & Maintenance Reality

Mount it in standard IP20 cabinets – no special cooling needed unless ambient exceeds 50°C. One caveat: in dusty cement plants, I’ve seen terminals corrode faster; recommend dielectric grease on connections. For maintenance: clean vents quarterly (compressed air works), verify relay contacts annually, and update firmware during planned shutdowns – it takes 8 minutes. Oh, and never daisy-chain power rails; give it dedicated 2.5mm² wiring.

Certifications That Actually Matter

CE marked (EN 61010-1), UL 61010B certified, and RoHS 3 compliant. The ISO 9001 stamp on Honeywell’s manufacturing docs? That’s why field failures stay under 0.5% in my experience. No fancy “lifetime warranty” promises – just 365 days of real coverage that starts when you install it.

Ordering & Guarantees (No Surprises)

50% advance payment gets it reserved – these move fast when plants need spares. Full payment before shipping. In-stock units ship in 1 week; custom-configured might take up to 4 weeks. All deliveries via FedEx/UPS/DHL with tracking. If it arrives damaged? Report within 24 hours – we’ll replace it no questions asked.

Reviews

There are no reviews yet.