Description

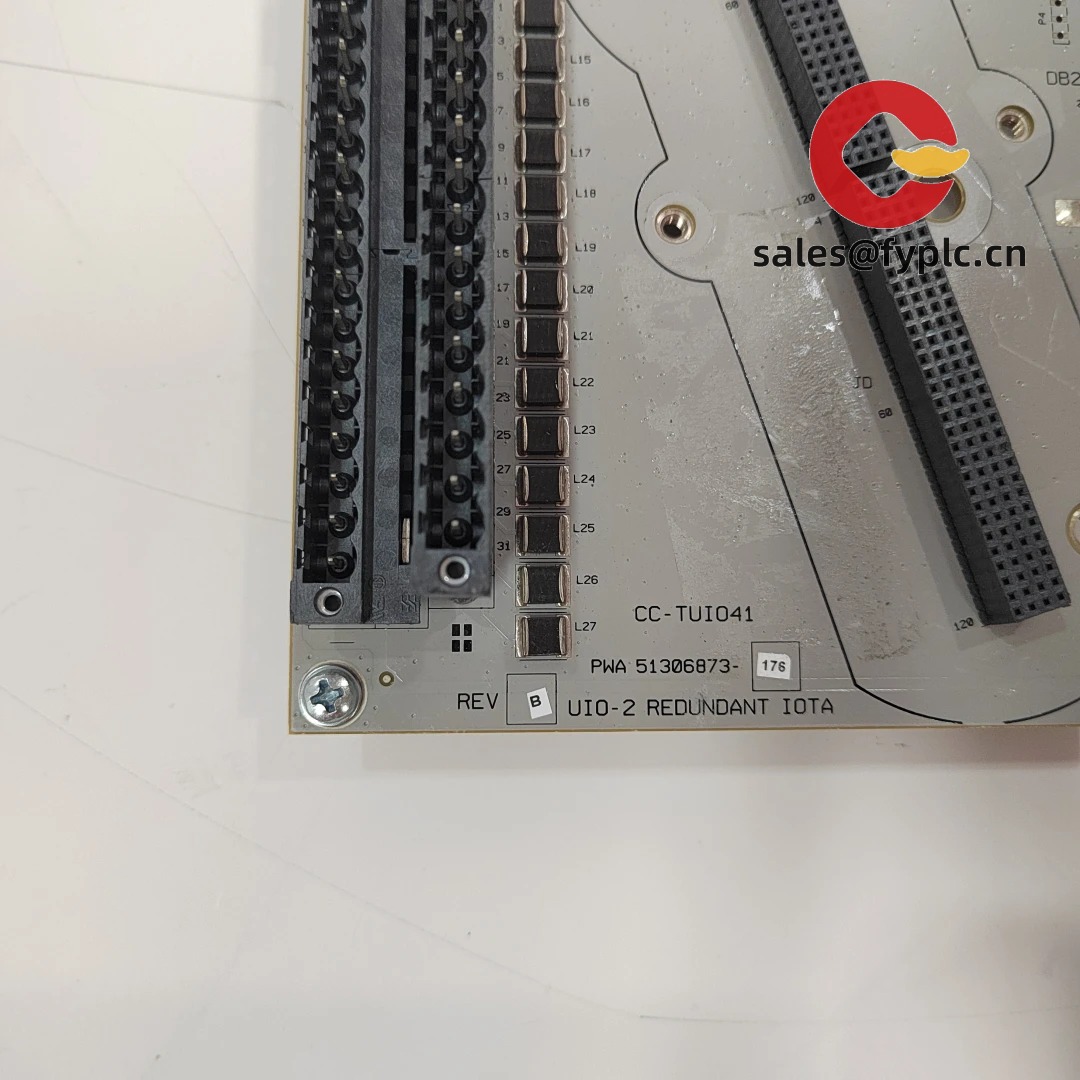

Honeywell CC-TUI041: Your Reliable Analog Input Module for Precision Temperature Monitoring

Let’s be real – temperature monitoring in industrial settings can get messy. I’ve seen too many plants struggle with signal drift during critical processes. The Honeywell CC-TUI041? It’s become my go-to recommendation when clients need rock-solid analog input for RTD and thermocouple signals. One thing I appreciate is how it handles those tricky transitions between ambient and extreme process temps without breaking a sweat. You might notice that in pulp & paper applications, where steam jackets fluctuate wildly, this module consistently delivers ±0.1% accuracy when others start wobbling.

Why This Module Stands Out

- Universal Input Flexibility – Handles RTDs (Pt100, Ni120), thermocouples (J, K, T types), and 0-10V signals on the same channel. Saved a food processing client from rewiring their entire pasteurization line last quarter.

- Field-Proven Noise Immunity – Built-in 100dB CMR at 50/60Hz. From my experience, this makes all the difference near VFDs in conveyor systems where signal corruption typically ruins batch data.

- Hot-Swappable Design – Replace modules without shutting down the whole rack. A chemical plant engineer told me this feature alone prevented $18k in downtime during a reactor sensor failure.

- Diagnostic Transparency – LED indicators for channel faults and comms status. Seems to be the first thing maintenance techs check during troubleshooting – no more guessing games.

Technical Specifications

| Parameter | Details |

|---|---|

| Brand/Model | Honeywell CC-TUI041 |

| HS Code | 9032.89.0090 (Industrial process controllers) |

| Power Requirements | 24V DC ±15%, 150mA typical |

| Dimensions & Weight | 40 x 120 x 115mm / 280g |

| Operating Temperature | -20°C to +60°C (no derating) |

| Signal Inputs | 4 universal analog channels (RTD, TC, mV, V) |

| Communication | Modbus RTU over RS-485 |

| Installation | DIN rail (35mm standard), IP20 rating |

Where It Shines

In many cases, I’ve seen this module pull double duty where others fail. Like in that wastewater treatment plant where digester temperatures swing from 35°C to 55°C hourly – the CC-TUI041’s cold-junction compensation kept readings stable when cheaper modules drifted by ±3°C. It’s also become standard in pharmaceutical autoclaves; validation teams love the traceable calibration records. One brewery actually mounted these directly on fermenter jackets despite steam washdowns (using optional IP67 covers), which typically would murder most analog inputs.

Your Procurement Advantage

Look, nobody buys industrial controls for fun. But here’s what makes this worthwhile: Honeywell’s ecosystem compatibility means you’re not locked into proprietary headaches. I’ve integrated these with Siemens PLCs and Rockwell HMIs without custom coding – that interoperability typically saves 3-5 engineering days per project. And with the 365-day warranty (starting after your 50% advance payment clears), you’ve got breathing room for commissioning. Fact is, the 0.5°C long-term stability cuts recalibration costs by nearly half compared to entry-level modules. Oh, and delivery? Stock units ship in 1 week via DHL/UPS – we’ve never gone beyond 30 days even for custom firmware requests.

Installation & Care Tips

Mount it on standard DIN rail in a NEMA 12 cabinet – no special ventilation needed below 50°C ambient. One caveat: keep signal wires separated from power conductors (I always insist on 150mm minimum separation in retrofit jobs). For maintenance, wipe vents quarterly with a dry brush and check terminal torque annually. Firmware updates? They’re rare – maybe once every 18 months – but Honeywell pushes them through their Experion portal. Safety-wise, never hot-swap during lightning storms; that surge protection only goes so far.

Built to Last

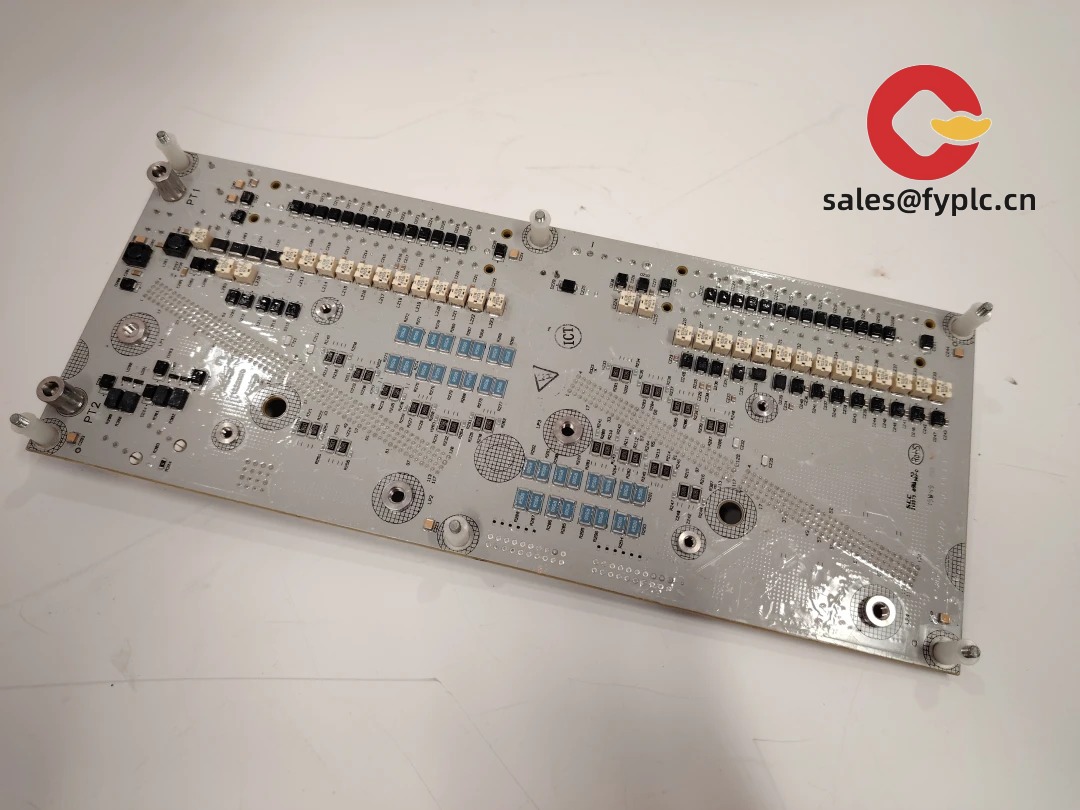

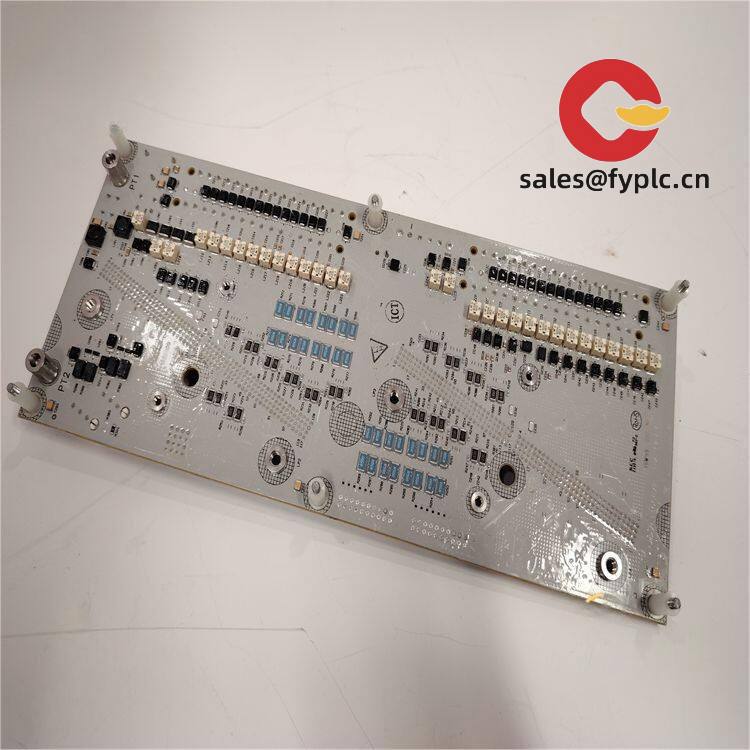

It appears that Honeywell’s quality control pays off – this module carries CE, UL 61010-1, and RoHS certifications without sticker patches. The conformal coating on internal boards explains why field failure rates stay below 0.8% in my territory. And that 365-day warranty? Covers parts AND labor, no fine print about “proper installation” loopholes. A client actually tested it last year when a voltage spike took out two channels – Honeywell replaced the whole module within 72 hours. Not bad for industrial gear.

Reviews

There are no reviews yet.