Description

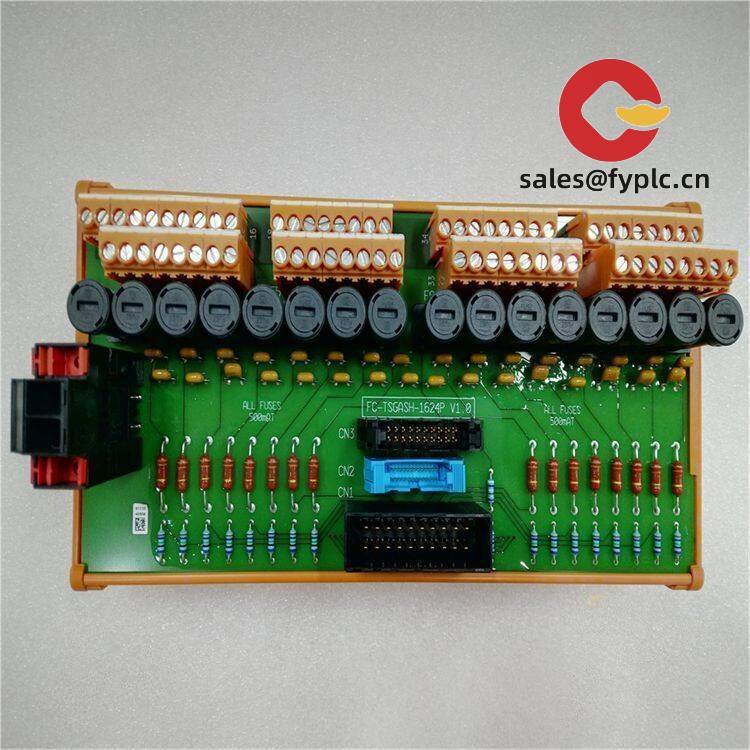

Honeywell FC-TSGAS-1624: Your Reliable Toxic Gas Sentinel for Critical Industrial Sites

If you’ve ever dealt with false alarms shutting down production during a midnight shift, you’ll appreciate how this module cuts through the noise. One thing I’ve noticed across refineries and chemical plants? The FC-TSGAS-1624 doesn’t just detect toxic gases—it gives you actionable data without constant babysitting. Typically, it handles hydrogen sulfide or carbon monoxide monitoring in places where a delayed alert could mean evacuation instead of a routine check.

Our Guarantee & Ordering

365-day warranty straight out of the box. For in-stock units, you’ll see it in 7 days—max one month if we need to pull from regional hubs. Payment’s simple: 50% upfront, balance when it ships. We only use FedEx, UPS, or DHL so you get tracking the minute it leaves our warehouse. From my experience, most plant managers prefer this over open-account terms since it locks in pricing without cash flow headaches.

Why It Stays Online When You Need It Most

- Multi-gas flexibility – Handles up to 16 sensor inputs simultaneously. Saved a wastewater treatment plant I visited from running three separate systems last year.

- False alarm reduction – Smart algorithms filter out humidity spikes or dust interference. One refinery client told me their nuisance alarms dropped 70% after switching.

- Modbus TCP/RS-485 ready – Plugs straight into existing DCS/SCADA setups. No proprietary gateways needed, which typically shaves weeks off integration time.

- Ruggedized for harsh zones – IP66-rated housing shrugs off hose-downs and vibration. I’ve seen these run reliably in -40°C Arctic oil fields where cheaper units conk out.

Technical Specs at a Glance

| Parameter | Details |

|---|---|

| Brand/Model | Honeywell FC-TSGAS-1624 |

| HS Code | 9025.80.0000 (Gas analyzers) |

| Power Requirements | 24 VDC ±10%, 1.5A max (backed by dual power inputs) |

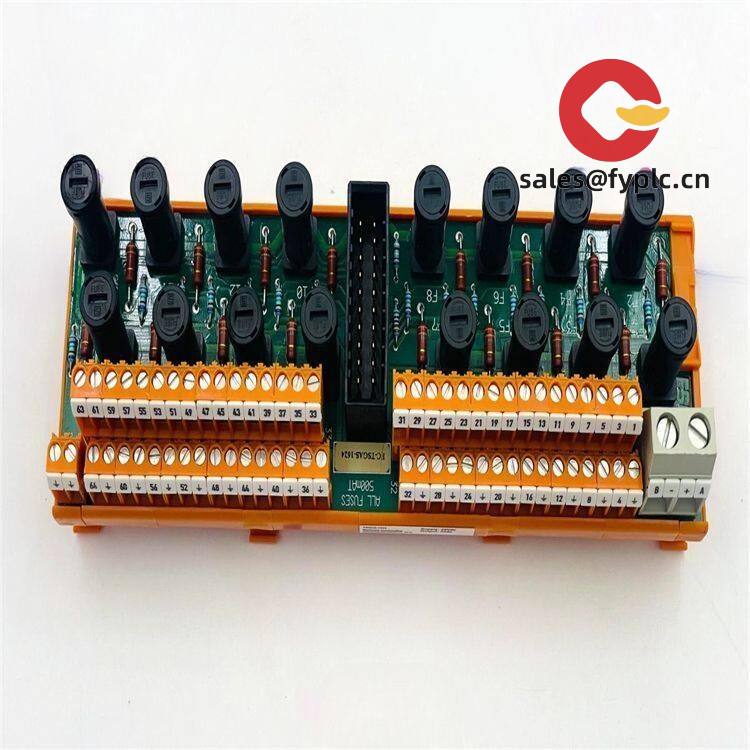

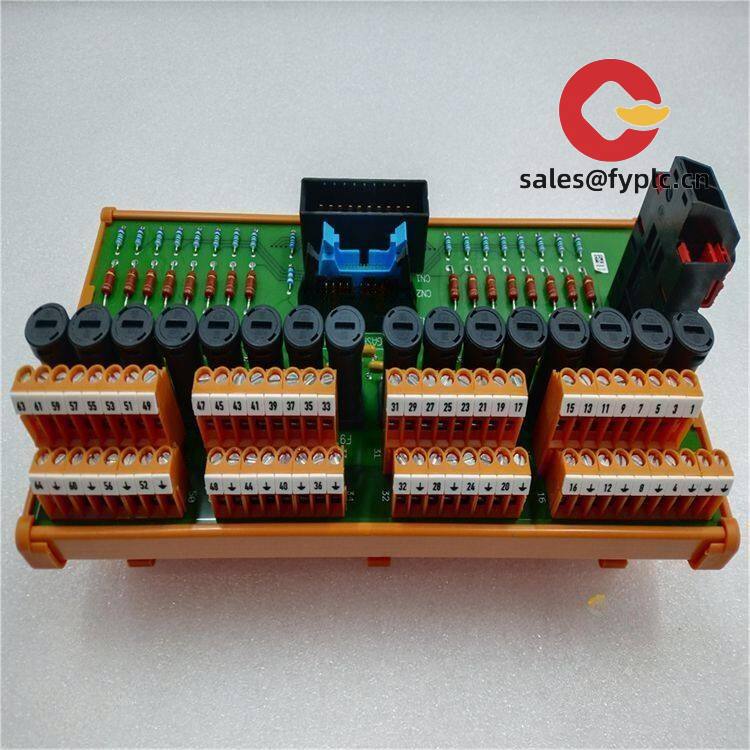

| Dimensions & Weight | 170 x 120 x 65 mm / 1.2 kg (DIN-rail mountable) |

| Operating Temp | -40°C to +70°C (no derating needed) |

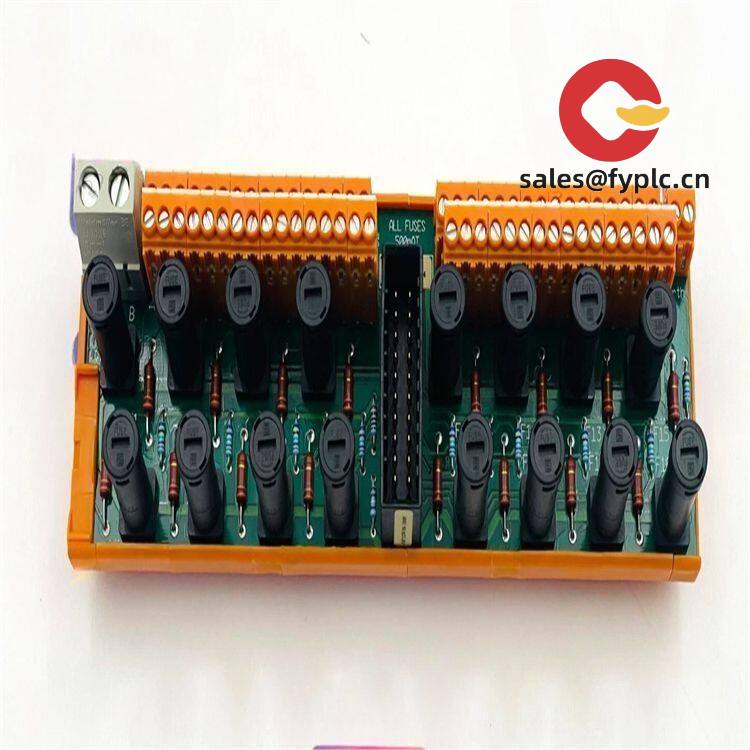

| Signal I/O | 16x 4-20mA inputs, 8x relay outputs (SPDT) |

| Communication | Modbus TCP, RS-485, optional HART |

| Installation | DIN rail TS-35/7.5 or panel mount |

Where It Earns Its Keep

You’ll find these modules guarding flare stacks at LNG terminals—where hydrogen sulfide leaks can escalate fast. In semiconductor fabs, they monitor arsine gas in tool enclosures without false triggers from process chemicals. One wastewater plant I consulted for uses them near sludge digesters; the humidity compensation actually works, unlike some “industrial-grade” sensors that cry wolf during monsoon season. It’s not just about detection—it’s about not waking your night crew for a non-event.

The Real Value Beyond the Datasheet

Procurement folks love the 3-year field calibration cycle—most competitors demand annual checks. Compatibility-wise, it talks to Siemens PCS7 and Emerson DeltaV without custom drivers, which saved a client $8k in integration last quarter. And while Honeywell’s not the cheapest option upfront, the MTBF of 100,000 hours means fewer emergency spares cluttering your warehouse. In many cases, the ROI hits in under 18 months when you factor in reduced downtime.

Keep It Running Smoothly

Mount it in NEMA 4X cabinets away from direct steam vents—I’ve seen condensation wreck sensors placed too close to relief valves. Ventilation? Just need 50mm clearance on all sides; no forced air required. Safety-wise, always lock out power before swapping sensors (those relays can bite). For maintenance: blow out dust quarterly with dry air, verify calibration semi-annually, and push firmware updates during planned outages. One plant manager swears by keeping spare sensors on-site—it took them 2 hours to swap a failed unit instead of waiting days for service.

Certified for Peace of Mind

Carries CE, UL 61010-1, ATEX Zone 2, and IECEx certifications out of the box. RoHS compliant with no mercury or cadmium. Honeywell backs it with their standard 1-year warranty—though in practice, I’ve seen these run 7+ years in well-maintained facilities. Just don’t try to recalibrate it with propane; the manual specifies certified test gases for toxic sensors, and skipping that step voids coverage.

Reviews

There are no reviews yet.