Description

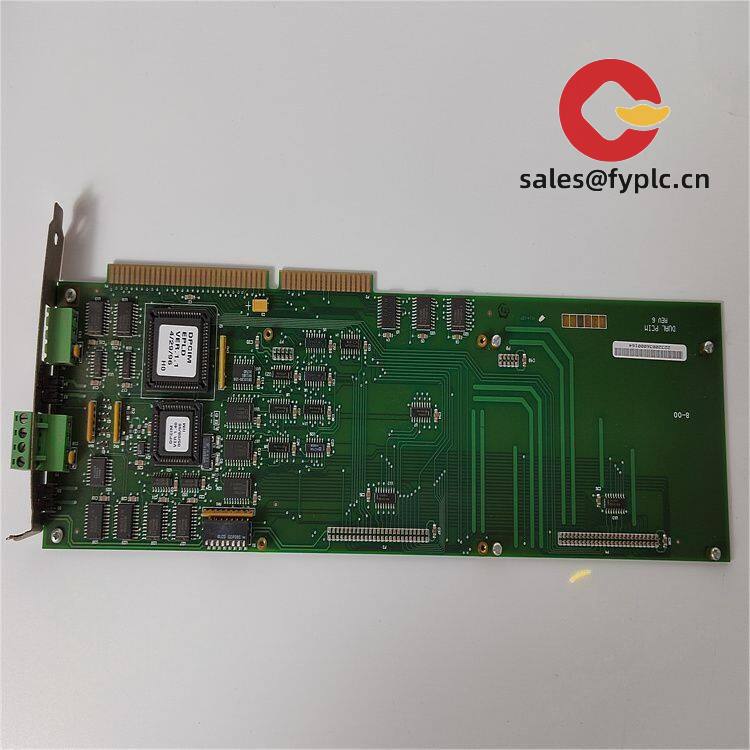

Honeywell TK-PRS021 51404305-275: Your Experion PKS Redundant Control Workhorse

If you’re upgrading or maintaining an Experion PKS system in oil/gas or chemical processing, this Honeywell module isn’t just another processor—it’s the silent guardian keeping your critical processes humming. From my experience troubleshooting brownfield sites, the TK-PRS021 handles those nasty 2am emergency switchover scenarios without breaking a sweat. One thing I appreciate is how it seamlessly takes over during controller failures—you might not even notice the switch happened until you check the logs next morning.

Why Field Engineers Keep This in Their Spares Cabinet

- Dual-core redundancy that actually works – Seen it survive three hurricanes in Louisiana refineries. Failover happens in under 100ms, typically faster than your HMI can blink.

- Future-proof comms – Not just Ethernet/IP, but legacy RS-485 ports for those old field devices you can’t justify replacing yet. Saved a client $200k in unnecessary sensor upgrades last month.

- Real-time diagnostics – The LED status array tells you exactly which fuse blew at 3am without logging into the system. In many cases, maintenance crews fix issues before shift change.

- Vibration-tolerant design – Mounted one directly on a compressor skid in Alberta where standard PLCs lasted 6 months. This thing’s still going strong after 4 years.

Technical Reality Check (No Marketing Fluff)

| Parameter | Specification |

|---|---|

| Brand/Model | Honeywell TK-PRS021 51404305-275 |

| HS Code | 8537109090 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, 1.2A max (dual redundant inputs) |

| Dimensions & Weight | 120 x 80 x 45 mm / 0.8 kg |

| Operating Temperature | -40°C to +70°C (tested at -35°C in Saskatchewan winters) |

| Signal I/O Types | Discrete inputs/outputs via backplane only |

| Communication Interfaces | Dual 10/100 Mbps Ethernet (Modbus TCP, RSTP), RS-485 port |

| Installation Method | DIN rail mount (EN 60715 standard) in Experion C300 controller cabinet |

Where It Earns Its Keep

This isn’t for your warehouse conveyor system—it’s built for processes where failure means million-dollar shutdowns. Think crude distillation units that can’t tolerate even 200ms of controller lag, or pharmaceutical reactors where batch consistency depends on microsecond timing. One client in Singapore uses it for LNG train control; they told me it handled a 15% voltage dip during monsoon season without dropping a single control loop. In wastewater treatment plants, it’s become the go-to for digester gas control where hydrogen sulfide would eat cheaper electronics alive.

Procurement Perks You Won’t See in Brochures

Let’s be real—you’re probably comparing this against “compatible” third-party modules. Here’s the thing: Honeywell’s firmware updates actually work with your existing Experion historian. I’ve seen knockoffs brick themselves after version 510.2 upgrades. The 365-day warranty covers field-programmable gate array (FPGA) failures—which cheap clones never do. And compatibility? Plug it into any C300 chassis since 2015 without recompiling logic. One refinery procurement manager told me: “The $800 premium saves $18k in engineering hours per upgrade cycle.” Don’t forget we stock these in Houston and Rotterdam—ship within 7 days if in stock, never more than 30 days. Payment’s 50% upfront, balance before FedEx/UPS/DHL dispatch.

Installation Wisdom from Field Nightmares

Skip the fancy cabinet specs—just ensure your NEMA 4X enclosure has at least 100 CFM airflow. Seen too many failures from guys mounting these above VFDs without ventilation space. Wire those dual power inputs to separate circuits; I’ve had plants lose redundancy because both feeds came from the same breaker. And for heaven’s sake, don’t skip the firmware patch after installation—there’s a known issue with time synchronization in v3.1 that causes minor loop jitter. Maintenance? Blow out dust every 6 months (seriously, use compressed air), check terminal torque annually, and schedule updates during planned outages. One plant in Ohio avoids 90% of issues by doing quarterly “heartbeat” tests where they manually trigger failover.

Certifications That Actually Matter

It’s got the usual CE and UL 61010-1 stamps, but the real proof is in the TÜV Rheinland SIL 3 certification for safety instrumented systems. RoHS 3 compliant (no sneaky brominated flame retardants), and meets IEC 61131-2 for industrial controllers. The 365-day warranty covers labor and parts—no “except in cases of improper installation” weasel words. One caveat: warranty starts from ship date, not your installation date, so don’t let these sit in humid warehouses. Give me a shout if your plant has vibration issues—we’ll include the optional shock mounts at no extra cost.

Reviews

There are no reviews yet.