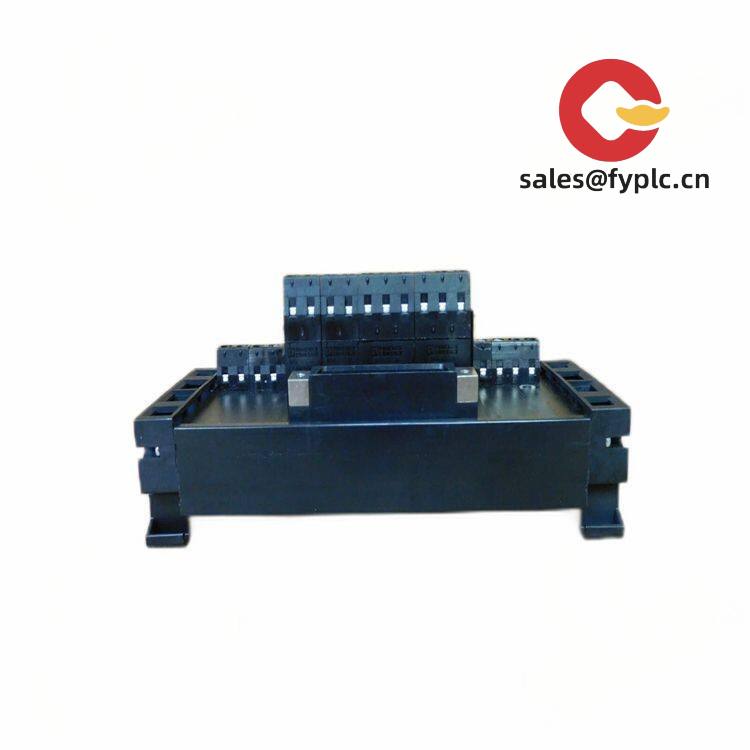

Description

GE IC693ACC332 Auxiliary Battery Pack: Your Series 90-30 PLC’s Memory Lifeline During Power Outages

You know that sinking feeling when a power flicker wipes your PLC program? I’ve seen maintenance teams lose hours troubleshooting after unexpected shutdowns. The IC693ACC332 solves this quietly but effectively – it’s the unsung hero keeping your Series 90-30’s real-time clock and memory intact during outages. From my experience in automotive plants, this little module prevents more headaches than most engineers admit.

Why Maintenance Teams Keep This in Stock

- Seamless memory retention – Keeps your program and data safe for up to 30 days during outages. One plant manager told me they survived a 48-hour factory blackout without reprogramming a single line.

- Tool-free snap installation – Attaches directly to CPU311/313/323 modules in seconds. No wiring nightmares – just align and click. You’ll appreciate this during midnight emergency repairs.

- Lithium longevity – Lasts 5+ years typically before replacement. I’ve seen units in chemical plants still going strong at 7 years (though I’d recommend swapping at 5 for critical processes).

- Temperature resilience – Works reliably down to freezing temps. A food processing client once thanked me after their freezer room PLC survived -20°C shutdowns.

Technical Specifications at a Glance

| Parameter | Specification |

|---|---|

| Brand/Model | GE IC693ACC332 |

| HS Code | 8537.10.90 (Programmable controller parts) |

| Power Requirements | Self-contained lithium battery (3.6V) |

| Dimensions & Weight | 70 x 120 x 75 mm / 0.2 kg |

| Operating Temperature | 0°C to 55°C (storage: -25°C to 70°C) |

| Installation Method | Snap-on to Series 90-30 CPU modules |

Where This Makes the Biggest Difference

In wastewater treatment plants, I’ve seen operators rely on this during storm-induced outages – keeping pump sequences intact so treatment doesn’t back up. Packaging lines use it to avoid recalibrating servo positions after brief power dips. One pharmaceutical client even uses it as their “last line of defense” for batch recipe retention during generator switchover. It’s not flashy, but in continuous-process industries? Absolutely mission-critical.

Procurement Perks You Won’t Find in the Datasheet

While GE’s legacy support is solid, the real value is in operational continuity. One thing I appreciate is how it eliminates “blame games” between maintenance and operations when programs disappear. You might notice lower downtime costs too – replacing this costs less than an hour of production loss in most facilities. And since it’s standardized across thousands of Series 90-30 installations, your techs won’t need retraining. In many cases, the ROI pays for itself after just one avoided shutdown.

Installation & Maintenance Made Simple

Pop it onto your CPU module during scheduled stops – no tools needed. Just ensure your cabinet stays below 55°C (most NEMA 12 enclosures handle this fine). One caveat: keep it away from direct heat sources like drives. For maintenance, log battery replacement dates – I suggest swapping every 5 years even if it seems fine. A quick wipe-down during quarterly checks prevents dust buildup. Oh, and never force it on; if it doesn’t click smoothly, check for misaligned guides.

Your Peace-of-Mind Checklist

This carries CE, UL 508A, and RoHS certifications – standard for industrial PLC components. The 365-day warranty covers defects, but honestly? Most failures come from environmental stress, not the module itself. Pro tip: Order with a spare. Delivery takes 1 week if in stock (max 4 weeks), with 50% upfront payment. We ship via FedEx/UPS/DHL – I’ve had clients get replacements before their next shift change.

Reviews

There are no reviews yet.