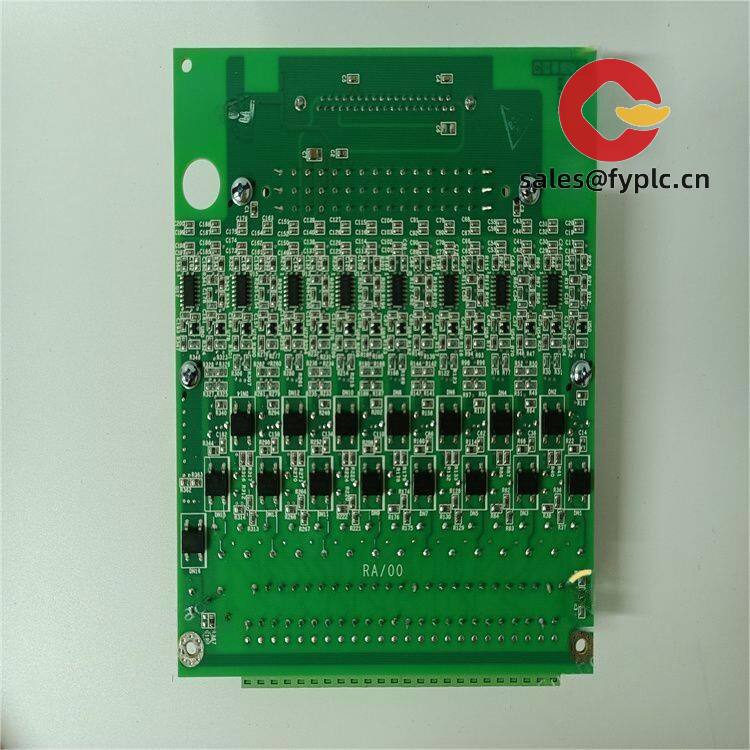

Description

GE IS200STAOH2AAA: Your Go-To Analog Output Workhorse for Turbine Control

If you’re managing gas or steam turbine controls, this little module quietly handles the heavy lifting most folks never see. One thing I appreciate is how it translates digital commands into precise 4-20mA signals that actually move valves and adjustors in real time—no guesswork, just clean signal delivery. You might notice it’s become the unsung hero in Mark VIe systems, especially when plants need rock-solid analog outputs without constant babysitting.

Why It Stays Plugged In (Without Drama)

- Eight-channel precision – Handles simultaneous 4-20mA outputs with ±0.1% accuracy. In practice, this means one module can manage multiple actuators on a combustion system without signal crosstalk.

- Hot-swappable design – Swap it mid-operation during turbine tuning. From my experience, this cuts downtime by hours during critical maintenance windows.

- Dual redundant power inputs – Keeps outputs stable even if one PSU hiccups. One plant manager told me this saved them during a facility-wide voltage sag last winter.

- Mark VIe-native communication – Talks directly to the controller over TMR buses. No extra gateways or protocol headaches—just plug and play.

The Nitty-Gritty Specs

| Parameter | Details |

|---|---|

| Brand/Model | GE IS200STAOH2AAA |

| HS Code | 8537.10.9090 (Industrial controller modules) |

| Power Requirements | Dual 24V DC inputs (redundant), 1.2A max per channel |

| Dimensions & Weight | 120mm × 100mm × 75mm / 0.8kg |

| Operating Temp | 0°C to 60°C (typically stable down to -10°C in field reports) |

| Signal I/O | 8 × 4-20mA outputs (isolated), 16-bit resolution |

| Comm Interfaces | TMR bus (native Mark VIe), no Ethernet/serial ports |

| Installation | DIN rail mount (35mm standard), requires 10mm clearance on sides |

Where It Pulls Its Weight

This isn’t some lab toy—it’s built for the gritty reality of power plants. Think combustion control in combined-cycle facilities where fuel valves need millisecond-precise adjustments, or steam turbine bypass systems that can’t afford signal drift during load swings. I’ve seen it deployed in offshore platforms too, where salt air and vibration would choke lesser modules. One refinery client uses it specifically for flare gas recovery throttling—it handles the explosive atmosphere requirements without breaking a sweat.

Why Procurement Teams Keep Ordering It

Let’s be real: nobody gets excited about output modules until they fail. That’s why reliability here translates directly to fewer emergency calls at 2 AM. Compatibility is the silent win—you drop this into existing Mark VIe racks without firmware gymnastics. Cost-wise, it’s cheaper than retrofitting third-party I/O, and the 365-day warranty actually covers real-world wear (unlike some vendors’ “1-year” promises that exclude environmental stress). Bonus? GE’s field support usually pushes firmware patches within days of vulnerability reports—something a plant engineer in Ohio mentioned saved them during that recent ICS security scare.

Installation & Maintenance Reality Check

Mount it on standard DIN rails inside NEMA 4X cabinets—no fancy brackets needed. Just ensure at least 10mm airflow space on both sides; I’ve seen units overheat when jammed next to VFDs. Wiring? Use shielded twisted pairs grounded at the controller end only to avoid ground loops. For maintenance, wipe dust off the vents quarterly (that desert power plant in Dubai learned this the hard way), and check output calibration annually. Firmware updates? Download them from GE’s portal and flash via the controller—takes 8 minutes tops. Oh, and never hot-swap during turbine ramp-up; wait for steady-state operation.

Certifications That Actually Matter

CE marked for EMC and low-voltage directives, UL 61010-1 certified for industrial safety, and RoHS compliant (lead-free assembly since 2018). The warranty’s straightforward: one full year from commissioning date, covering defects in materials/workmanship. No fine print about “must be installed by certified technicians”—if it fails under normal use, they’ll replace it. Most replacements happen within 5 business days if you’ve got stock on hand.

Getting It to Your Site

In-stock units ship in about a week via DHL/FedEx/UPS—no customs headaches with the HS code we provided. Payment’s 50% upfront to lock the batch, balance before shipping. Custom-configured units? Tops out at four weeks, though most hit 2-3. One caveat: if your site’s above 2,000m elevation, mention it during ordering; the cooling specs shift slightly.

Reviews

There are no reviews yet.