Description

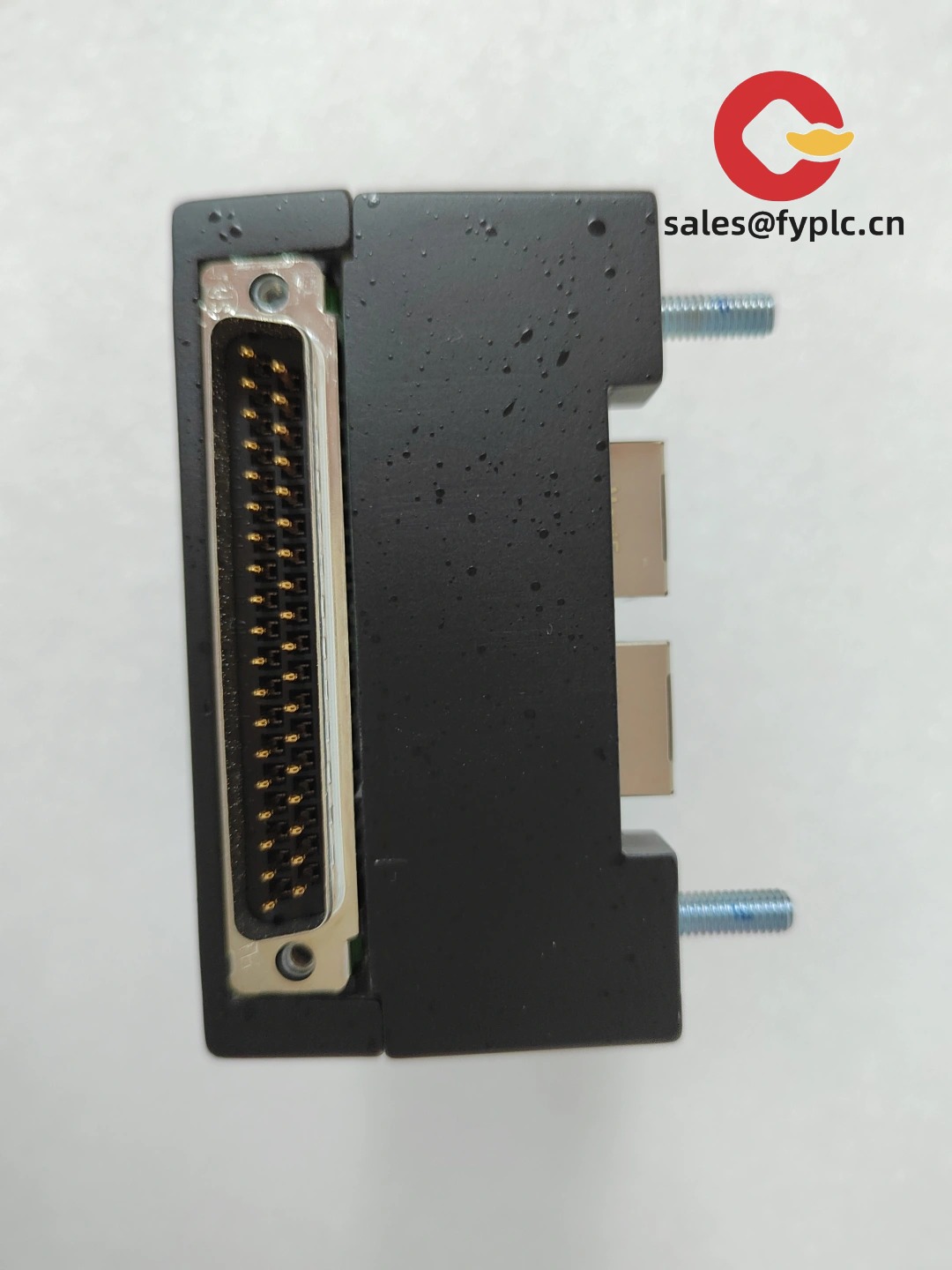

GE IS220PRTDH1BC: Your Reliable RTD Input Module for Precision Temperature Monitoring

If you’re wrestling with inconsistent temperature readings in your industrial processes, this GE Mark VIe module might just become your new best friend. From my experience troubleshooting turbine control systems, one thing I appreciate is how this RTD input module quietly handles those finicky platinum resistance thermometers without breaking a sweat. You’ll typically find it humming along in power plants or chemical facilities where a single degree off could mean costly downtime.

Order Placement & Guarantees

- Full 365-day warranty covering defects (starts from installation date)

- In-stock units ship within 1 week – nothing takes longer than 30 days

- Payment: 50% upfront, balance before shipment (FedEx/UPS/DHL options)

Key Features That Actually Matter

- 8-channel RTD support – Handles Pt100/Pt1000 sensors without constant recalibration headaches. In many cases, this cuts wiring costs by eliminating signal conditioners.

- ±0.1°C accuracy – You might notice tighter process control in distillation columns where temperature gradients make or break product quality.

- Hot-swappable design – Swap modules during runtime (yes, really). One refinery client told us this saved 14 hours of unplanned downtime last quarter.

- Profibus DP interface – Integrates smoothly with Siemens PLCs. Typically avoids those messy protocol gateway expenses.

Technical Specifications

| Parameter | Details |

|---|---|

| Brand/Model | GE IS220PRTDH1BC |

| HS Code | 8537.10.9000 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, 1.2A max |

| Dimensions & Weight | 120 x 180 x 75 mm / 0.8 kg |

| Operating Temperature | -20°C to +70°C (non-condensing) |

| Signal Inputs | 8x 3-wire RTD (Pt100/Pt1000) |

| Communication | Profibus DP, Mark VIe backplane |

| Installation | DIN rail (EN 60715) – fits standard 40mm rail spacing |

Where It Actually Gets Used

This isn’t some lab curiosity – you’ll spot it monitoring critical assets where temperature stability is non-negotiable. Think gas turbine bearing housings that run 24/7, or pharmaceutical reactor vessels where batch consistency depends on precise thermal control. One wastewater treatment plant I worked with uses it for digester temperature management; they told me it finally solved their seasonal sludge processing fluctuations. In pulp mills, it’s common to see these on steam drum level control systems where RTD drift used to cause unnecessary shutdowns.

Why Procurement Teams Keep Ordering It

Let’s be real – you’re not just buying a module. You’re buying fewer midnight emergency calls. The compatibility with existing Mark VIe systems means your techs won’t need weeks of retraining (unlike some newer “smart” modules that require full system overhauls). From a cost perspective, the hot-swap feature alone typically pays for itself in one avoided shutdown. And GE’s firmware updates? They actually fix real problems – last month’s patch addressed that intermittent comms dropout issue some plants were seeing with high-vibration equipment.

Installation & Maintenance Reality Check

Mount it in standard NEMA 12 cabinets with at least 50mm clearance on both sides – I’ve seen too many failures from cramming these next to VFDs. Ventilation matters more than you’d think; keep ambient temps below 60°C if you want to hit that ±0.1°C spec consistently. For maintenance, skip the monthly calibrations unless you’re in a high-dust environment (like cement plants). What actually helps? Blowing out the vents quarterly with dry air and checking terminal torque every 6 months. Oh, and update firmware during planned outages – not when things are melting down.

Certifications & Quality Assurance

It’s CE marked and UL 61010-1 certified – no paperwork nightmares for your safety team. GE’s manufacturing follows ISO 9001 with component traceability back to batch numbers (handy when you’re debugging field issues). The warranty covers full replacement for defects, but here’s what’s not in the brochure: their support engineers actually answer the phone. One client in Alberta called during a -40°C winter outage and had remote diagnostics running in 22 minutes. Not bad for industrial gear.

Reviews

There are no reviews yet.