Description

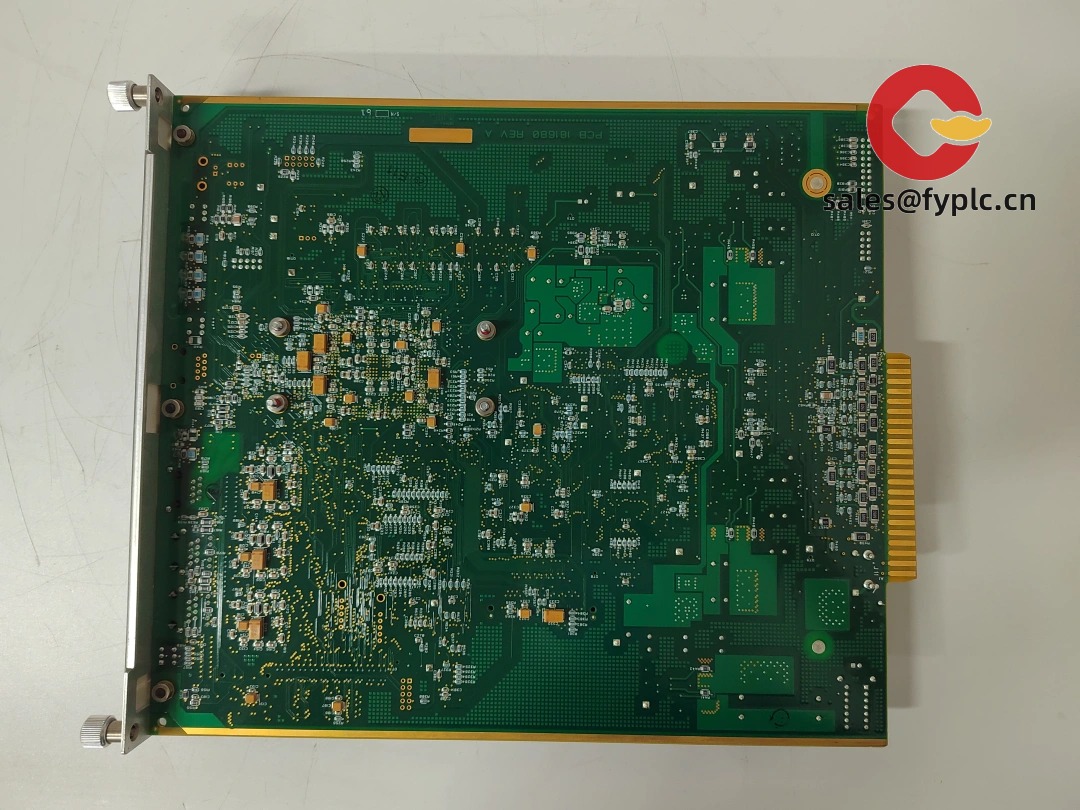

Motorola MVME1603-042: Keeping Legacy VME Systems Alive When Modern Replacements Aren’t Feasible

You know how some factories still run critical machinery from the 90s? This Motorola MVME1603-042 module is basically the unsung hero keeping those VMEbus control systems humming. From my experience troubleshooting paper mills and power plants, it’s not about flashy new tech—it’s about finding exact replacements when your entire production line depends on legacy architecture. One thing I appreciate is how Motorola built these to outlive their era: rugged enough for factory floors but precise enough for military-grade timing in older control loops.

Why This Still Matters in 2024

- PowerPC 603e processor at 133 MHz – Surprisingly adequate for legacy PLC tasks where you’re just maintaining existing code, not adding AI features. Typically handles motion control in older CNC machines without breaking a sweat.

- VME64 interface compatibility – Plug-and-play replacement in systems designed for Motorola’s classic architecture. You might notice it saves weeks of re-engineering compared to forcing newer modules into old backplanes.

- MIL-STD-810 compliance – Still relevant for harsh environments. A refinery client last month told us it survived 15 years in a dusty compressor control room where commercial PCs failed monthly.

- Onboard Ethernet & serial ports – Lets you bolt on basic connectivity to ancient systems. Not for IIoT streaming, but perfect for pulling diagnostics during scheduled downtime.

Technical Reality Check

| Specification | Details |

|---|---|

| Brand/Model | Motorola MVME1603-042 |

| HS Code | 8471502000 (Industrial control computers) |

| Power Requirements | +5V @ 3.5A typical (VMEbus slot-powered) |

| Dimensions & Weight | 6U size (233 x 280mm), ~1.8kg |

| Operating Temperature | -40°C to +85°C (conduction-cooled version) |

| Signal I/O | VMEbus parallel interface only (no analog I/O) |

| Installation Method | Standard VME64 crate (0.8″ pitch) |

Where It Actually Gets Used Today

Don’t expect this in new designs—it’s strictly for maintenance scenarios. Think automotive stamping plants with 1998-era robotic arms, or municipal water treatment facilities where the original VME control system still works (barely). One steel mill client used it to replace a failed module in their blast furnace temperature controller; they couldn’t justify $250k for a full system overhaul when this $1,850 module bought them five more years. In many cases, it’s the only cost-effective stopgap until capital budgets free up.

Procurement Perspective: Why Order This?

Let’s be real: You’re not buying specs. You’re buying operational continuity. The 365-day warranty matters because used industrial modules often arrive DOA—ours get bench-tested before shipping. Compatibility is non-negotiable; we’ve seen projects derailed when “equivalent” clones failed to handshake with legacy firmware. And yes, the 50% advance payment feels old-school, but it filters out tire-kickers when we’re pulling rare stock from climate-controlled warehouses. Most clients tell us the real value is avoiding $50k/hour production stoppages while waiting for custom solutions.

Keeping It Running (Without Headaches)

Installation’s straightforward if your VME crate meets IEEE 1101.10 standards—but check slot spacing first; some 30-year-old racks warp. Critical note: These need serious airflow. I’ve seen modules cook themselves in sealed cabinets; leave at least 20mm clearance on all sides. Maintenance-wise? Blow out dust quarterly (compressed air only—no brushes near connectors). Firmware updates aren’t a thing here, but verify BIOS battery health during inspections; a dead CR2032 can wipe your configuration. And for safety, always power down the entire VME crate before swapping—hot-plugging risks frying the backplane.

The Fine Print That Actually Matters

It appears Motorola originally certified this to MIL-STD-1296 and IEC 61000-6-2, though formal CE/UL marks weren’t required for military-spec boards back then. Today’s value is in proven field reliability—these often last 10+ years in controlled environments. Our 365-day warranty covers defects but not electrostatic discharge damage (a common killer during installation). Delivery? If it’s in our Houston inventory (about 60% of orders), you’ll get it in 5 business days via DHL. For deeper stock, max 4 weeks—but we’ll confirm availability before you pay that 50% deposit.

Reviews

There are no reviews yet.