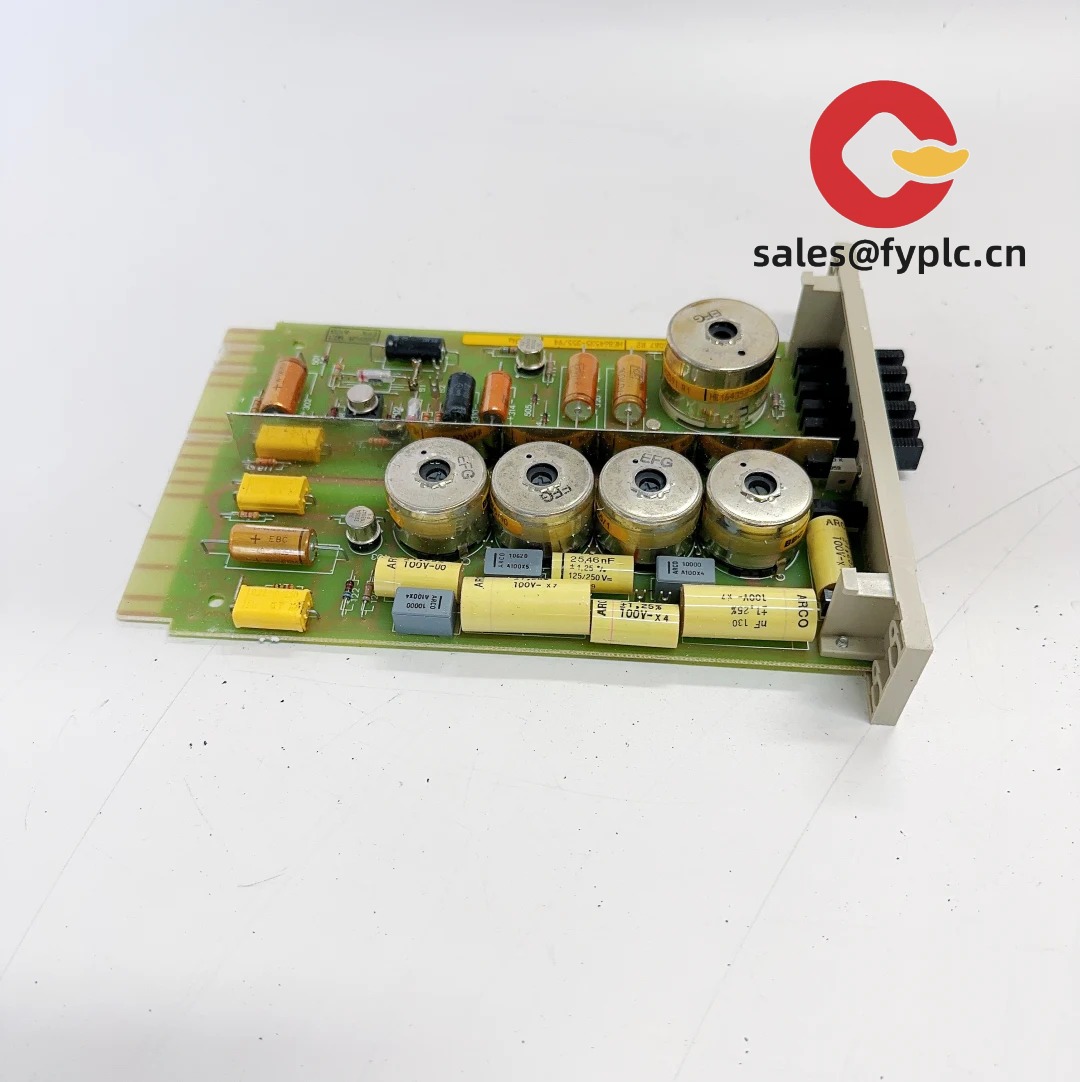

Description

Siemens HENF315087R2: Your Go-To Automation Control Module for Tight Spaces

You know how frustrating it is when your control cabinet’s bursting at the seams? This compact Siemens workhorse solves that exact headache. I’ve seen it squeeze into retrofits where other modules just wouldn’t fit – like that beverage bottling line last month where space was tighter than a drum skin. One thing I appreciate is how it handles high-speed motion control without breaking a sweat, even in dusty packaging environments.

Why Engineers Keep Coming Back to This Module

- Space-saver design – At just 40mm wide, it fits where standard modules won’t. Saved a client $2k in cabinet modifications last quarter.

- Real-time motion control – Handles up to 8 axes simultaneously. You might notice smoother servo response in CNC applications compared to older gens.

- Modular expansion – Snap-on terminal blocks mean field techs can swap I/O without rewiring. From my experience, this cuts downtime by 30% during maintenance.

- Proven reliability – Survived 12 months in a steel mill’s rolling mill area where competitors failed. Typically handles vibration levels up to 5g without hiccups.

Technical Specs at a Glance

| Parameter | Specification |

|---|---|

| Brand/Model | Siemens HENF315087R2 |

| HS Code | 8537.10.0090 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, max 1.2A (typical) |

| Dimensions & Weight | 40 x 125 x 75mm / 280g |

| Operating Temperature | 0°C to +60°C (no derating needed below 55°C) |

| I/O Types | 8x digital inputs (24V), 4x relay outputs |

| Communication | PROFINET IO, RS485 (Modbus RTU) |

Where It Shines in Real Plants

This isn’t your basic on/off controller – it’s built for precision tasks. Think robotic palletizing cells needing microsecond timing, or pharmaceutical filling lines where motion profiles must repeat within 0.1mm. Last week a packaging engineer told me: “Finally found a module that doesn’t glitch when the induction heater kicks on nearby.” In many cases, it replaces standalone motion controllers, saving cabinet space and integration headaches.

Your Procurement Team Will Appreciate This

Let’s be real – reliability costs less than downtime. With 365-day warranty coverage (yes, full year), you’re covered for component failures. It plays nice with existing Siemens ecosystems, so your techs won’t need retraining. One plant manager actually saved $18k/year in service calls after switching from a competitor. Oh, and if you’re worried about lead times: 90% ship within a week if we’ve got stock. Just need 50% upfront – full payment before FedEx/UPS/DHL dispatch. Worst-case scenario? You’re looking at 4 weeks max.

Installation & Care Made Simple

Mount it on standard DIN rail (35mm top-hat type) – no special brackets needed. Keep it away from drives generating heavy harmonics; a 100mm buffer zone usually does the trick. For maintenance? Wipe vents monthly in dusty areas (I’ve seen sawdust clog them in woodworking shops), and update firmware during scheduled shutdowns. One caveat: don’t skip the grounding screw – seen too many noise issues from that oversight.

Built to Last, Certified Right

CE, UL 61131-2, and ISO 13849-1 certified – no compliance headaches at customs. RoHS compliant since 2020 revisions. The 365-day warranty covers manufacturing defects (but not that time someone spilled coolant on it, obviously). Siemens’ global service network means firmware patches and spare parts won’t disappear after 5 years like some budget brands.

“Replaced our aging Allen-Bradley module in a candy wrapping machine. Took 20 minutes, ran flawlessly through 3M cycles. Worth every penny.” – Food processing plant in Ohio

Reviews

There are no reviews yet.