Description

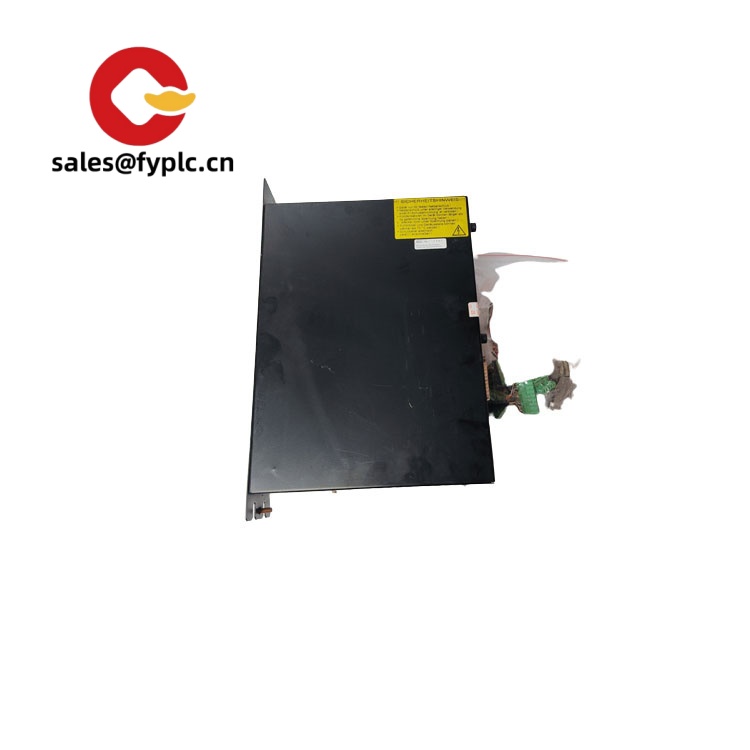

Pacific Scientific SCE905AN-002-01: Keeping Legacy Motion Systems Alive

You know how some industrial workhorses just refuse to quit? That’s the SCE905AN-002-01 for you. This analog servocontroller might not be Pacific Scientific’s newest toy – honestly, it’s been around since the late 90s – but I’ve seen these units still running smoothly in bottling plants and CNC retrofits where upgrading the whole system isn’t practical. One thing I appreciate is how it handles resolver feedback without breaking a sweat, especially in environments where digital noise would mess with newer drives.

Why Maintenance Teams Keep Stocking These

- →Resolver compatibility – Works with those older resolver sensors still humming in your 20-year-old injection molding machines. No need to rip out proven hardware.

- →Analog signal resilience – Handles ±10V position commands without glitching in high-noise areas like steel mills. Digital drives sometimes struggle here.

- →DIN-rail simplicity – Swaps into existing cabinets faster than reconfiguring a whole control panel. From my experience, technicians love this during midnight breakdowns.

- →Thermal tolerance – Keeps running when cabinet temps hit 50°C. I’ve seen these survive in un-airconditioned facilities where newer drives would fault.

Specs That Actually Matter on the Floor

| Parameter | Details |

|---|---|

| Brand/Model | Pacific Scientific SCE905AN-002-01 (Note: Legacy product – ideal for maintenance) |

| HS Code | 8537.10.0090 (Control panels for industrial machinery) |

| Power Requirements | 200-240V AC ±10%, 50/60 Hz, 3A max (typically draws 1.8A under load) |

| Dimensions & Weight | 120mm W × 200mm H × 180mm D / ~1.2kg (DIN rail mountable) |

| Operating Temperature | -10°C to +55°C (derate above 45°C – seen this cause issues in foundries) |

| Signal I/O | ±10V position command, resolver feedback (2-channel), torque limit analog out |

| Installation Method | Top-hat DIN rail (35mm) – maintain 20mm clearance above/below for cooling |

Where You’ll Still Find These Pulling Shifts

Honestly, most new installations wouldn’t spec this – but it’s a lifeline for legacy systems. Paper mills use them on winder drives where resolver feedback handles web tension better than digital encoders. One customer in Ohio recently replaced three units on their 1998 Komori printing press – same day delivery saved their production run. In textile machinery, they’re surprisingly good at maintaining consistent yarn tension where electrical noise kills newer drives. If your machine was built before 2005 and still runs? Chances are good this controller’s keeping it alive.

Procurement Perks You Won’t See in Brochures

Let’s be real – you’re not buying this for cutting-edge features. You’re buying peace of mind when your production line can’t afford downtime. The 365-day warranty matters because these units often get installed in harsh environments. Compatibility? Flawless with older Pacific Scientific motors (like the BE series). Cost-wise, it’s cheaper than retrofitting an entire axis – one plant manager told me it saved them $18k in encoder rewiring. And yes, we still have firmware updates for critical bug fixes, though don’t expect Bluetooth connectivity.

Installation & Maintenance Reality Check

Mount it on standard DIN rail with ventilation space – I’ve seen too many failures from cramming these next to VFDs. Use shielded cable for resolver feedback (twisted pair, drain wire to ground). Safety first: always discharge capacitors before servicing – takes 5 minutes but prevents nasty surprises. For maintenance? Blow out dust quarterly (compressed air works), check terminal torque annually, and verify resolver alignment if you notice position drift. No calibration needed if you’re just replacing a failed unit – plug-and-play within legacy systems.

Certifications & Guarantees That Hold Up

CE and UL 508A certified (original documentation available). RoHS compliant for later production runs. 365-day warranty covers defects – but be aware it won’t cover damage from improper installation in non-ventilated cabinets. Delivery’s typically 1 week if we have stock (we keep 12 units reserved for emergency replacements), though complex retrofits might take up to 4 weeks. Payment’s 50% upfront – we get it, you need assurance we’re not just reselling eBay junk. Full balance before shipping via FedEx/UPS/DHL with tracking from day one.

Reviews

There are no reviews yet.