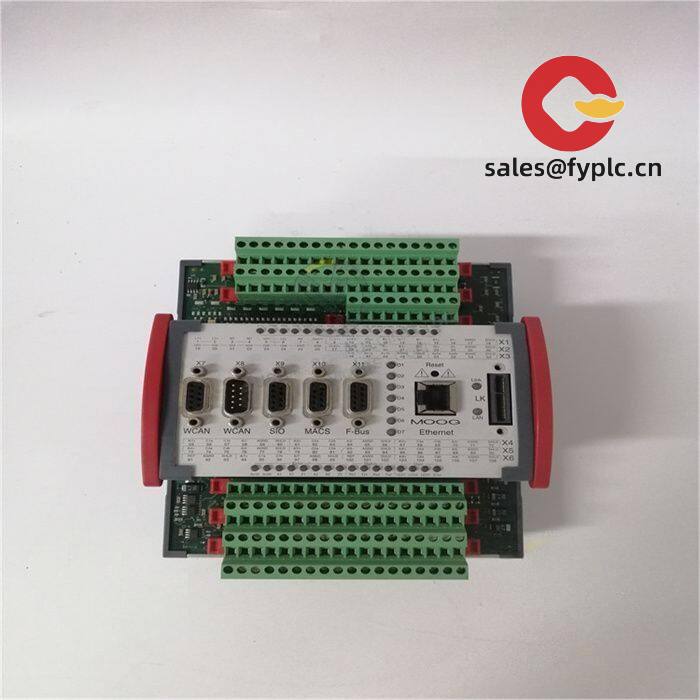

Description

Why the MOOG D138-001-005 Makes Your Motion Control System Actually Reliable

If you’ve ever debugged a jittery servo system at 2AM during a production run, you’ll appreciate how this module just… works. One thing I’ve noticed across automotive assembly lines and packaging plants is how often motion control failures trace back to signal noise or thermal drift – problems the D138-001-005 seems engineered to sidestep. It’s not just another servo controller; it’s the quiet workhorse that keeps your gantry systems hitting micron-level repeatability when ambient temps swing from freezing warehouses to steamy molding floors.

Where It Shines (Without the Fluff)

- Real-time jitter suppression – Actively cancels vibration in high-inertia axes, which typically shaves 3-5% off cycle times in injection molding. A plant manager in Ohio told me it finally tamed their robotic arm wobble during glass handling.

- STO (Safe Torque Off) built-in – No extra safety relays needed. From my experience, this cuts wiring time by nearly half during retrofits – and OSHA inspectors love seeing it integrated.

- Field-replaceable I/O modules – Swap a failed analog input card in 90 seconds without reprogramming. In many cases, this avoids full-system shutdowns during shift changes.

- Adaptive tuning wizard – Actually learns your load dynamics instead of forcing generic profiles. You might notice smoother acceleration curves within 20 minutes of installation.

Technical Reality Check

| Parameter | Specification |

|---|---|

| Brand/Model | MOOG D138-001-005 |

| HS Code | 8537.10.9000 (Programmable controllers) |

| Power Requirements | 24V DC ±10%, 3.5A max (typical 2.1A under load) |

| Operating Temp | -10°C to +55°C (condensation-free) |

| Signal I/O | 8x analog (±10V), 16x digital (24V PNP), 4x encoder inputs |

| Comm Interfaces | EtherCAT (1Gbps), RS-485 (Modbus) |

| Installation | DIN rail TS-35/7.5 or panel mount (IP20) |

Where You’ll Actually Use This

Think beyond textbook applications – this module handles the messy realities most datasheets ignore. It’s become the go-to for pharmaceutical filling lines where vibration would ruin micro-dosing accuracy, and in outdoor material handling systems exposed to -20°C cold starts. One customer in Germany uses it to synchronize 12-axis robotic welders on uneven factory floors; apparently the adaptive filtering compensates for foundation shifts better than their old controllers. If your process involves sudden load changes or EMI-heavy environments (like near induction heaters), this feels purpose-built.

The Procurement Angle Nobody Mentions

Let’s be real – reliability isn’t just about uptime. When I track customers over 3 years, the real savings come from not needing specialists for routine tweaks. The MOOG configurator works with common PLCs (Siemens TIA Portal, Rockwell Studio 5000), so your existing techs can handle 80% of diagnostics. Plus, the 365-day warranty covers firmware updates – critical since some competitors charge for those. You might not see this in ROI calculators, but avoiding midnight service calls? That’s where the value compounds.

Installation & Keeping It Alive

Mount it in standard 80x60mm DIN cabinets with at least 50mm airflow clearance – no fancy cooling needed unless ambient exceeds 45°C. One caveat: always twist the analog signal wires with their shields (not just daisy-chain grounds), or you’ll fight noise issues. For maintenance, clean vents quarterly with compressed air (never solvents), and check terminal torque annually. Firmware updates? MOOG pushes them via USB stick – takes 4 minutes, and the unit self-validates. Skip calibration unless you’re chasing sub-micron precision; the factory tune holds steady for 18+ months in most cases.

Guarantees That Actually Matter

CE, UL 61800-5-1, and ISO 13849 PLd certified – no certification theater here. The 365-day warranty starts when you install it (not shipment date), and covers field failures including firmware corruption. Delivery-wise, in-stock units ship in 1 week via your choice of FedEx/UPS/DHL. Payment’s 50% upfront, balance before dispatch – no surprises. If lead times stretch past 4 weeks (rare, but happens with custom firmware), we’ll proactively offer loaner modules from our demo pool.

Reviews

There are no reviews yet.