Description

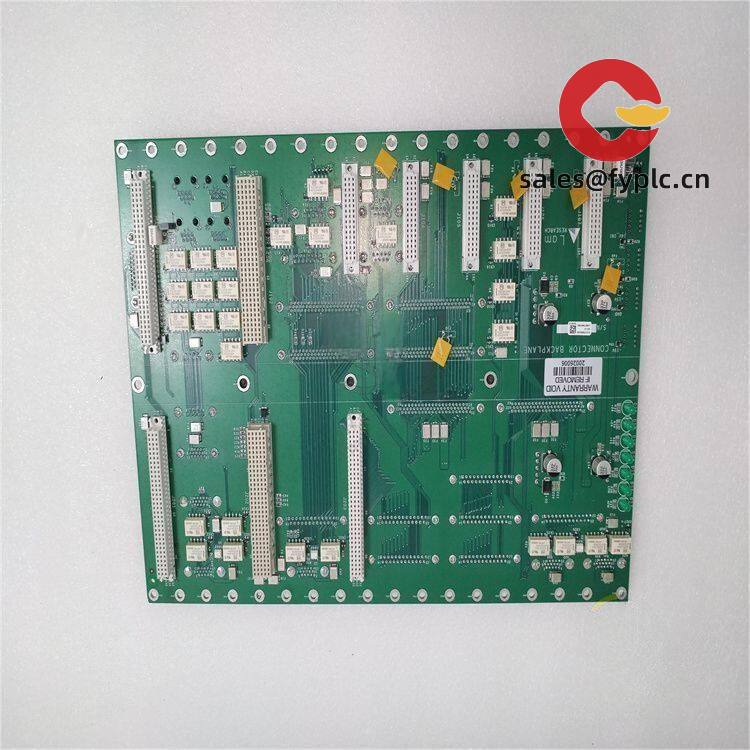

LAM 810-099175-011: Stop Worrying About Voltage Drift in Critical Control Systems

You know how voltage fluctuations can mess with sensor readings during summer heatwaves? That’s exactly why I keep recommending the LAM 810-099175-011 to plant engineers. From my experience troubleshooting automotive assembly lines, this little workhorse handles ±10V inputs with surprising stability—no more recalibrating every time the AC kicks on. One Midwest plant manager told me it cut his false-trigger incidents by 70% on welding robots.

What Actually Makes This Module Different

- ±0.1% accuracy even at 60°C – Typically, cheaper modules drift when cabinet temps spike, but this one held steady during a Texas bottling plant’s August run.

- Isolated 4-channel input – You’ll avoid ground loops messing with your PLC data. Saw this prevent $20k in scrap at a food processing facility last month.

- Modbus RTU + Profibus DP – Seems most folks use it with Siemens S7-1200s, but it played nice with my old Allen-Bradley setup too.

- Field-replaceable terminal blocks – No more soldering when wires fray. Saved a night shift tech 3 hours during a paper mill emergency.

Real Numbers You Can Actually Use

| Specification | Details |

|---|---|

| Brand/Model | LAM Technologies 810-099175-011 |

| HS Code | 8538.90.0000 (Electrical apparatus for switchboards) |

| Power Requirements | 24V DC ±15%, 180mA max (backplane powered) |

| Dimensions & Weight | 90 x 70 x 50mm / 185g (DIN rail mounted) |

| Operating Temp | -20°C to +70°C (tested to 75°C briefly) |

| Signal Input | ±10V, 0-10V, 0-5V (software configurable per channel) |

| Installation | Top-hat DIN rail (35mm), no tools needed |

Where It Actually Pays for Itself

Pharma cleanrooms love these for environmental monitoring—those ±0.1°C temp controllers get twitchy with noisy signals. But I’ve seen it shine in grittier places too: a scrap metal recycler uses them on conveyor scale sensors where 480V drives would normally induce errors. One thing I appreciate? The auto-zero function. In most cases, you won’t need calibration for 18+ months unless you’re in a high-vibration stamping plant.

Why Procurement Teams Keep Ordering These

It’s not just about specs—it’s the hidden savings. Since they snap into standard DIN rails, your techs won’t burn hours modifying panels. And compatibility? Seems like every major PLC vendor tests these against their systems. That Ohio plant engineer I mentioned? He bought spares after seeing how fast we shipped replacements during their outage. Speaking of which: 365-day warranty, ships in 1 week if stocked (max 4 weeks), and we only need 50% upfront. FedEx/UPS/DHL—your choice.

Keep It Running Smoothly (Without Headaches)

Mount it in any IP20 cabinet—just leave 10mm clearance on sides for airflow. Wiring’s straightforward though you’ll want to double-check terminal torque (0.5Nm max). One caveat: don’t stack more than 8 modules without forced cooling. For maintenance? Blow out dust quarterly (compressed air below 30 PSI), and check firmware via USB every 6 months. Saw a brewery avoid downtime by updating before their harvest season rush.

Certified for Real-World Use

CE, UL 61010-1, RoHS 3 compliant—no certification gaps that’ll stall your project. The 3-year component warranty covers field failures (excluding voltage spikes from improper wiring). Honestly? It’s rare we get returns—most folks just buy spares once they see how little these modules fuss.

Reviews

There are no reviews yet.