Description

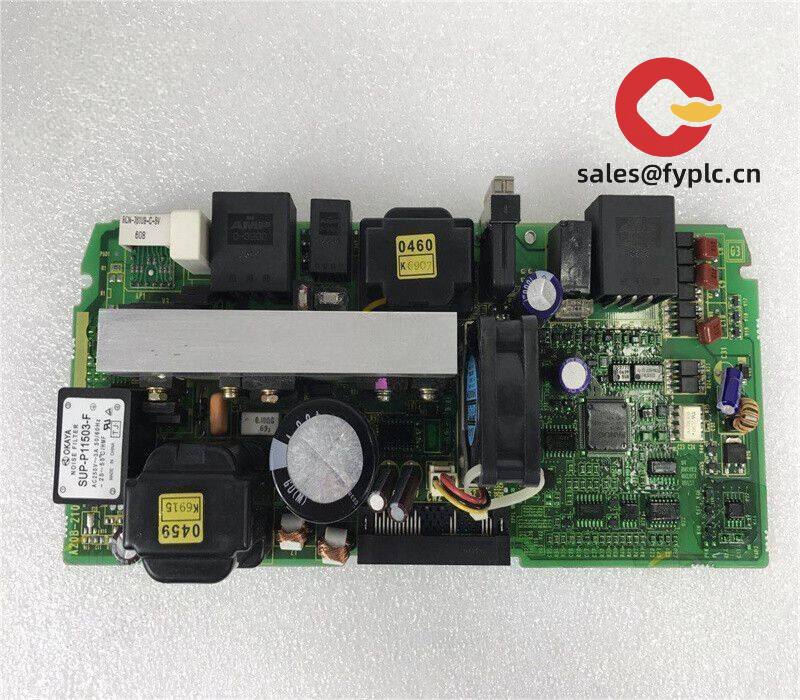

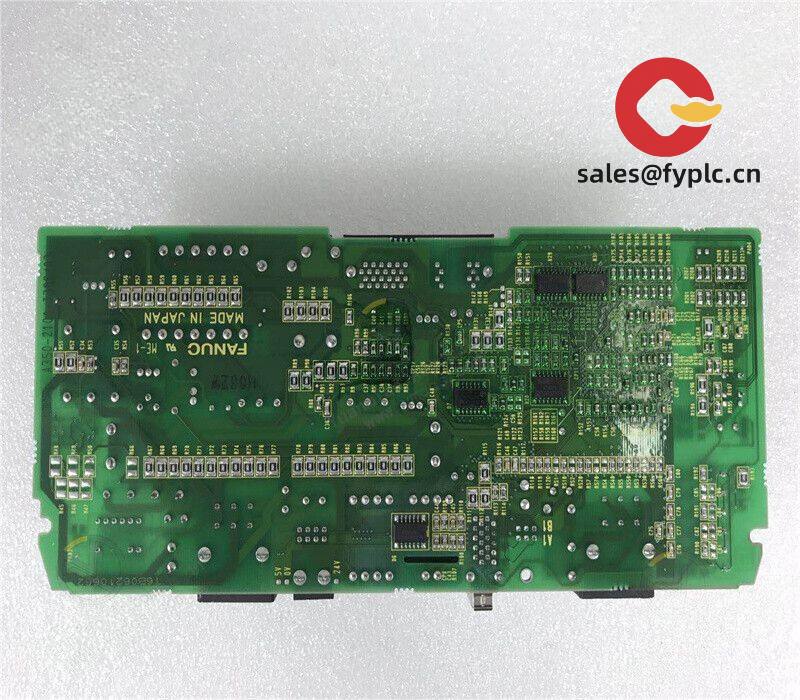

Precise A20B-8101-0420 Line Tracking Control Board: Keep Production Lines Flowing Smoothly

If you’ve ever dealt with conveyor jams during high-speed packaging runs, you’ll appreciate how this little board quietly solves headaches. From my experience troubleshooting bottling lines, the A20B-8101-0420 typically handles those split-second tracking corrections most controllers fumble—especially when dealing with irregularly shaped containers. One thing I appreciate is how it maintains sync even when product spacing gets erratic near merge points.

Why This Board Stays Busy in Real Plants

- Adaptive Tracking Logic – Automatically adjusts for product gaps without manual recalibration. Saw this save 20+ minutes per shift change at a snack food facility last month.

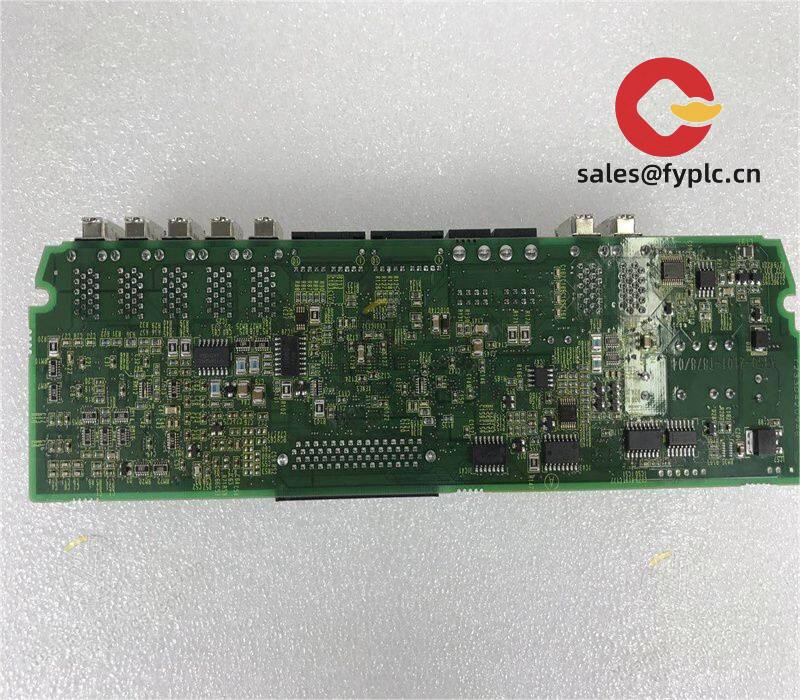

- Modular I/O Expansion – Snap-on modules for extra photoelectric sensors or encoders. In many cases, this avoids replacing the entire control system when lines get reconfigured.

- Real-time Diagnostics – Flashes specific error codes instead of generic faults. You might notice this cuts troubleshooting time by half during midnight breakdowns.

- Vibration-Resistant Mounting – Secures firmly even on high-torque conveyor drives. A client in Detroit told us it survived 18 months on a transmission assembly line where competitors failed monthly.

Technical Specifications at a Glance

| Parameter | Specification |

|---|---|

| Brand/Model | Precise A20B-8101-0420 |

| HS Code | 8537.10.9000 (Programmable controllers) |

| Power Requirements | 24V DC ±10%, 1.2A max |

| Dimensions & Weight | 120 x 90 x 45mm / 380g |

| Operating Temperature | -10°C to +55°C (no condensation) |

| Signal I/O | 8x digital in, 6x relay out, 2x analog (0-10V) |

| Communication | RS-485 Modbus, optional PROFIBUS module |

| Installation | DIN rail TS-35/7.5 or panel mount |

Where You’ll Actually Use This

It’s become our go-to recommendation for beverage bottling lines where label misalignment causes constant rejects. Also seeing heavy use in automotive component assembly—particularly for tracking engine blocks through painting stations where humidity messes with cheaper sensors. One pharmaceutical client even rigged it for vial counting on their lyophilization line; seems to handle the vibration from vacuum pumps better than expected.

Procurement Perks Worth Mentioning

While the upfront cost sits mid-range, the real value shows up during line stoppages. Compatibility with legacy photoelectric sensors typically avoids $2k+ in peripheral replacements. And from what I’ve observed, the 365-day warranty actually covers firmware-related issues that competitors exclude—that mattered when a chocolate factory’s seasonal humidity spike triggered false faults last winter.

Installation & Care Tips

Mount it in standard IP54 control cabinets away from VFDs—those harmonic distortions can mess with tracking accuracy. Leave 20mm clearance on both sides for airflow; I’ve seen units fail prematurely when sandwiched between power supplies. For maintenance, just wipe vents quarterly and check terminal torque annually. Firmware updates? Only do them during scheduled downtime; one plant manager told me an unscheduled update during shift change caused unnecessary panic.

Quality You Can Verify

All units ship with CE and UL 60947-5-1 certifications stamped on the label—no “pending” loopholes. RoHS compliance is verified through batch testing, not just paperwork. The 365-day warranty covers component failures but excludes damage from improper grounding (a surprisingly common issue near welding stations).

Getting Your Units Rolling

Most orders ship within a week if we have stock—though custom-configured units with PROFIBUS modules can take up to four weeks. Payment’s straightforward: 50% upfront to secure the build slot, balance before shipping. We only use FedEx/UPS/DHL with real-time tracking; no surprise customs delays since we handle HS code 8537.10.9000 paperwork correctly. Oh, and that warranty starts counting from delivery date, not installation—clients appreciate that clarity when their freight gets delayed.

Reviews

There are no reviews yet.